I just tried using my compressor and there is air leaking from where the filter is and where the metal coil is at. It feels like air leaking out from the spot where the metal coil attaches to the factory filter. Any idea what is wrong? I can feel the air hissing out where that nut is.

- The AGN App is ready! Search "Airgun Nation" in your App store. To compliment this new tech we've assigned the "Threads" Feed & "Dark" Mode. To revert back click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air venturi 4500 problem, air leak near filter

- Thread starter elittle1234

- Start date

It looks like a steel threaded nut, not sure about the type it is. I'm going to try changing the burst disc to see if that works. I don't know much about compressors lol

Upvote 0

If it's leaking by the tube nut in your photo, then it's not the burst disk and changing it will have no effect on the leak. Typically, this type of fitting is a compression type with a conical ferrule. These fittings will be damaged if you overtorque them to try and stop leaks. You can either make a new tube assembly, buy a tube assembly from OEM, or convert the entire connection with a hose rated for the pressure. With some soapy water, drip some on the tube nut to pinpoint the leak area. Most likely where the tube enters the nut.

Upvote 0

Changing the burst disc seems to have worked, but there is still air gushing out. Now I'm not sure if it's been doing this all along and if its supposed to or if it's broken. It filled 2 bottles to 4500 just fine.

Any one here have this AV 4500 compressor? Does yours have air being released out of the area of the burst disc while it runs?

Sorry for the noob questions but it is HPA so I really want to respect it and not blow my garage apart.

Any one here have this AV 4500 compressor? Does yours have air being released out of the area of the burst disc while it runs?

Sorry for the noob questions but it is HPA so I really want to respect it and not blow my garage apart.

Upvote 0

Check for leaks with soapy water or paper flag, not fingers (painful and potentiallt deadly). Burst disk shouldn't leak. Compression fitting looks loose (tube off center in nut, it is possible for it to be that way but not usually).

Upvote 0

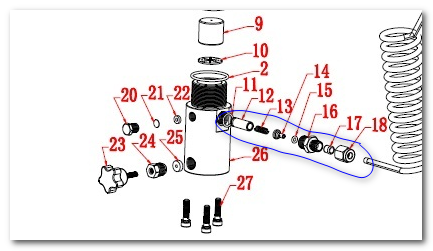

Agree with Sergey, pinpoint the leak area first. It could be the fitting that screws into the filter housing or the compression nut tightness itself. Also make sure it's just not the bleed valve leaking a little bit. It won't hurt anything to unscrew the compression nut while holding a back-up on the other fitting so it don't unscrew at the same time you're unscrewing the compression nut. After you loosen the compression nut and it turns freely you might have to lightly tap on the tubing while pulling out on it to break the seal. While you're at it go ahead and pull the other fitting. There is a check valve behind that fitting that might need cleaning. Going back together snug up the first fitting, start the compression nut and again hold a back up on the first fitting and snug the compression fitting up. It's just a good practice I think to use the back up method. Here's a snippet of the fittings and the internal check valve.

Upvote 0

If by changing your burst disk allowed pressure to build, you had two leaks. You apparently fixed one of them. Your original post only mentioned the leak at the fitting in the photo.

So it appears you know pretty close to zero about HPA compressors. But that’s OK, nobody on this site woke up one morning and overnight the great creator downloaded certain knowledge into our brain bucket. I admire your wanting to diagnose and repair and ask on AGN for assistance. Good move.

The fitting that another member asked you about (compression fitting) is shown in the photo I attached. The whitish line in the photo is a plastic line but in your case it’s actually a stainless steel line.

Starting on the left side of the photo, that is the fitting body. The next piece is called a front ferrule, the next piece is a back ferrule and the hex piece is a compression nut.

A gas seal is achieved of course by tightening the nut to a specific torque or number of turns of the nut, specified by the manufacturer of that fitting.

I worked for a company named Swagelok who, what we were told, invented the design in the 1960’s I believe. Anyway, on 1/4” and 6mm tubing the fitting is tightened 1 1/4 turns to create the seal.

We were taught when loosening the compression portion of the fitting to put a Sharpie match mark on the fitting body and compression nut. Upon re-tightening you tighten a little past the match marks. Most people don’t do that in the real world but that’s how we were trained. Note: different size tubing was tightened to different numbers of revolutions.

To determine where the leak is on your fitting as mentioned, start by putting a drop of soapy water where the tube enters the compression nut, then at the left side of the nut and then finally check where the fitting body screws into the compressor water seperator. Most often the leak is usually at one or both sides of the compression nut.

Also, DO NOT loosen or tighten pressure fittings while they are pressurized, they can burst and shrapnel can fly at very high velocity or a high pressure jet of air can pierce your skin and cause an air embolism.

Be careful, read, ask, learn.

So it appears you know pretty close to zero about HPA compressors. But that’s OK, nobody on this site woke up one morning and overnight the great creator downloaded certain knowledge into our brain bucket. I admire your wanting to diagnose and repair and ask on AGN for assistance. Good move.

The fitting that another member asked you about (compression fitting) is shown in the photo I attached. The whitish line in the photo is a plastic line but in your case it’s actually a stainless steel line.

Starting on the left side of the photo, that is the fitting body. The next piece is called a front ferrule, the next piece is a back ferrule and the hex piece is a compression nut.

A gas seal is achieved of course by tightening the nut to a specific torque or number of turns of the nut, specified by the manufacturer of that fitting.

I worked for a company named Swagelok who, what we were told, invented the design in the 1960’s I believe. Anyway, on 1/4” and 6mm tubing the fitting is tightened 1 1/4 turns to create the seal.

We were taught when loosening the compression portion of the fitting to put a Sharpie match mark on the fitting body and compression nut. Upon re-tightening you tighten a little past the match marks. Most people don’t do that in the real world but that’s how we were trained. Note: different size tubing was tightened to different numbers of revolutions.

To determine where the leak is on your fitting as mentioned, start by putting a drop of soapy water where the tube enters the compression nut, then at the left side of the nut and then finally check where the fitting body screws into the compressor water seperator. Most often the leak is usually at one or both sides of the compression nut.

Also, DO NOT loosen or tighten pressure fittings while they are pressurized, they can burst and shrapnel can fly at very high velocity or a high pressure jet of air can pierce your skin and cause an air embolism.

Be careful, read, ask, learn.

Last edited:

Upvote 0

Here’s a link to some good info on common HPA compression fittings.

www.beswick.com

www.beswick.com

The Basics of Compression Fittings

Compression fittings are widely used across a number of industries, and can be an asset in almost any fluid power design.

Last edited:

Upvote 0

If it filled two bottles to 4500# I don't think you have a leak that is gushing out. It would be next to impossible to fill to that pressure. Could it be the air from the motor's fan? It'll hit about where you're looking and feeling the air moving.Changing the burst disc seems to have worked, but there is still air gushing out. Now I'm not sure if it's been doing this all along and if its supposed to or if it's broken. It filled 2 bottles to 4500 just fine.

Any one here have this AV 4500 compressor? Does yours have air being released out of the area of the burst disc while it runs?

Sorry for the noob questions but it is HPA so I really want to respect it and not blow my garage apart.

Upvote 0

I'm going to look like a fool here but I'll admit to it, it might have been air blowing out some part in the bottom I'd never noticed before that is totally normal. I did find a small leak in one of my fill whips that was making a hissing noise. I replaced that and now everything seems to be like it was before.

Upvote 0

That "some part in the bottom" was more than likely the air coming off the fan. Glad it's working out though.

Upvote 0

Or the drain valve.That "some part in the bottom" was more than likely the air coming off the fan. Glad it's working out though.

Upvote 0