Hi guys,

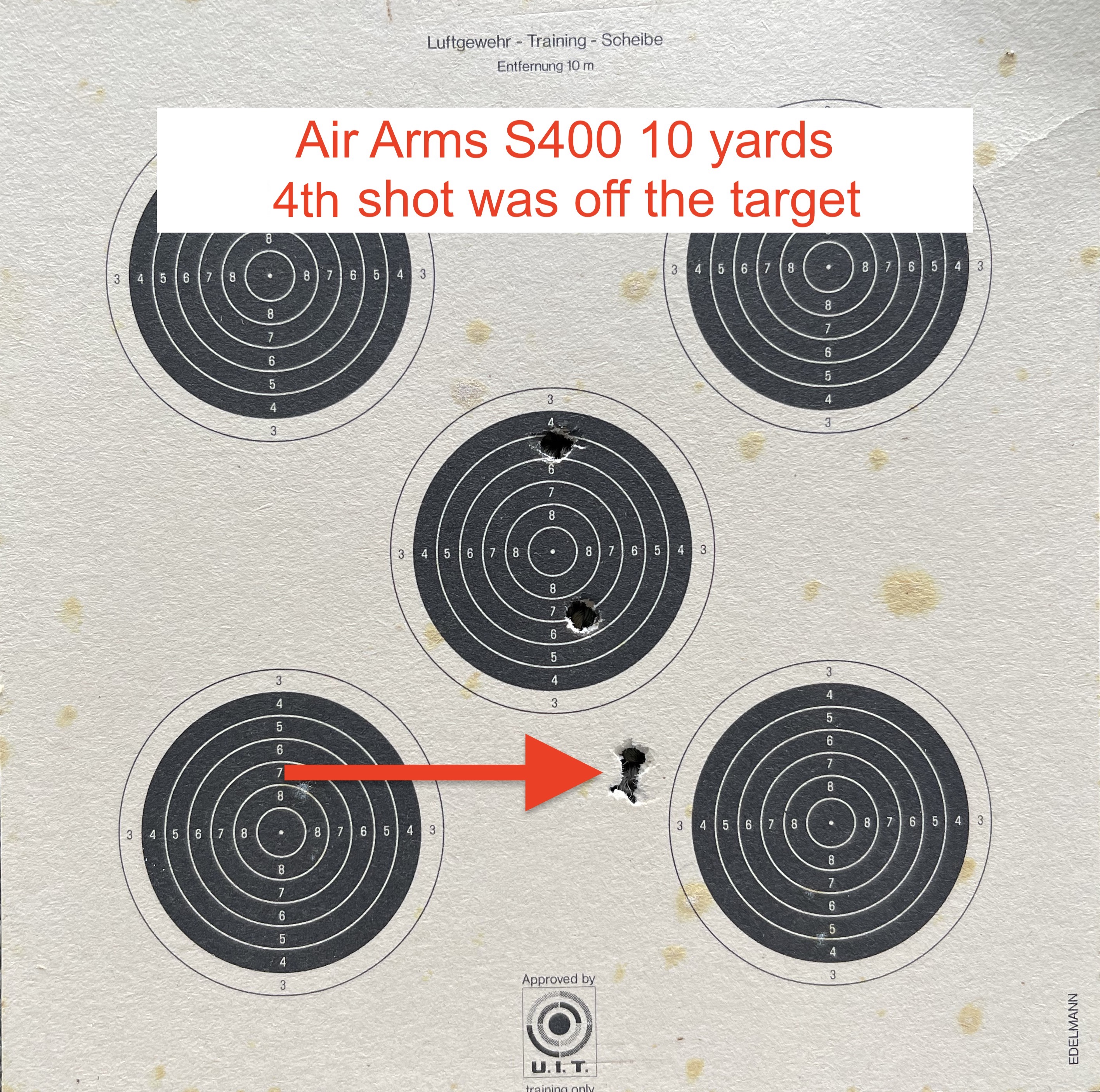

I gave my reliable S400 to my neighbor. He brought it back saying it wasn't hitting the target. I thought it needed air since it was low. I filled it up and it was hitting all over the place. I mean crazy. I thought it was the cheap scope and put a trusty Leupold on and it was still having issues. The last target (see below) showed that it's keyholing.

I looked down the muzzle, and I could be wrong, but the centerline of the bore looks like it is out of alignment compared to the baffle or whatever you call the end of the barrel on the Air Arms. It looks like the bullet would hit the baffle. But, I can't see any marks showing bullet strike. My question is if this is possible with the air arms barrel? Can it get out of alignment with the baffle if it was dropped or took a hit?

Thanks,

Dave

I gave my reliable S400 to my neighbor. He brought it back saying it wasn't hitting the target. I thought it needed air since it was low. I filled it up and it was hitting all over the place. I mean crazy. I thought it was the cheap scope and put a trusty Leupold on and it was still having issues. The last target (see below) showed that it's keyholing.

I looked down the muzzle, and I could be wrong, but the centerline of the bore looks like it is out of alignment compared to the baffle or whatever you call the end of the barrel on the Air Arms. It looks like the bullet would hit the baffle. But, I can't see any marks showing bullet strike. My question is if this is possible with the air arms barrel? Can it get out of alignment with the baffle if it was dropped or took a hit?

Thanks,

Dave