Has anyone put the high output valve and 4500 psi bottle from African air ordinance on the texan .257 im curious what the result where. I can't find any info searching online or the forums.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

African air ordinance Texan 257

- Thread starter Seth0764

- Start date

I have the valve arriving this next week. Jeremy said the tank would follow and is coming direct from the manufacture although I will probably not use it. I have already put on a carbon fiber tank and will most likely continue to use it at the 3600 psi fill. I cracked the seat on the OEM valve shooting it at 3600 psi. See photo. Hopefully the AAO valve will flow more air than the OEM valve at the 3600 PSi fill.

Here is a post I made on results with the CF tank and 3600 PSI.

https://www.airgunnation.com/topic/i-feel-the-need-for-speed-new-cf-tank-on-the-small-bore-texan-257/

Here is a post I made on results with the CF tank and 3600 PSI.

https://www.airgunnation.com/topic/i-feel-the-need-for-speed-new-cf-tank-on-the-small-bore-texan-257/

Upvote 0

Cool! my lss version arrived yesterday. I look forward to seeing your results with the new valve

Upvote 0

Waste of money. The 257 valve is a 308 valve. It is way over bore size.

Plus the 257 shoots bullets faster then there accurate already. Specially if you add a 3600 psi tank.

If you want a better poppit I could make you one. Simple cheap fix

Plus the 257 shoots bullets faster then there accurate already. Specially if you add a 3600 psi tank.

If you want a better poppit I could make you one. Simple cheap fix

Upvote 0

Waste of money. The 257 valve is a 308 valve. It is way over bore size.

Plus the 257 shoots bullets faster then there accurate already. Specially if you add a 3600 psi tank.

If you want a better poppit I could make you one. Simple cheap fix

At the same pressures it performs no better than the OEM valve, based results shooting across a Magnetospeed v3. Pressures up to 3625 PSI. I see no point going to higher pressures. First losing usable fill pressure from a SCBA bottle, and second it would only push bullets into the transonic speed but not get well into supersonic speed killing accuracy. The barrel twist rate will not stabilize heavier bullets so no way to use that 4500 PSI power.

The valve seat poppet does look more robust than the OEM part, which is why I went ahead on bought the AAO valve. But it was kind of a performance bust.

Upvote 0

If the twist was 1-12 could it be enough for 100 to 108 g .. because the texan with a 3600 psi fill could easily push 110g in the 950fps...because as far I have read the 1-10 has not been a success story..

Upvote 0

From the twist rate calculator it looks like 1:12 would be too slow. 1:10 looks okay by not great. My money would be on a 1:9 to 1:7. I seem to recall TJ’s options was 14, 10, & 7 . The sub sonic speed seems to need more twist based on looking at results from the calculator.

But look at it this way. The 257 Texan even with the 1:14 twist barrel is still probably the AG BC Speed King.??

But look at it this way. The 257 Texan even with the 1:14 twist barrel is still probably the AG BC Speed King.??

Upvote 0

Yup...but I just wanted a second barrel .. to push 3 of my molds that have 100g + accurately..rcbs 100 - 257-418 --- 257-325 ...Q.. does a airgun could have the power for such a fast twist..? I will write him to se if he could have a mandrel made -- Loren what do you think of a 1: 8.5 Twist...in the middle of 9 n 7..? Twist

Upvote 0

Why not get the 1:7? Being a little fast doesnt seem to effect the smaller calibers. I have shot 65 gr in my 1:14 and it shoots 92 gr just the same

Upvote 0

I agree with Doug, just go with the 1:7. I have thought about a second .257 Texan with a 1:7 barrel so I could shoot this bullet. But to just have a second barrel to swap, it would not be worth it to me. The 1:14 is really the right twist for a very broad range of bullet weight. Like Doug said 60gr to 90+gr. it shoots them all well.

Upvote 0

Thanks.. a lot .Loren. n Dyotat100.. for me I already have a custom condor with the Doug valve , hammer n spring..with 29" tj shooting awesome...will contact tj to see if he has the 1-7 available....

Upvote 0

I repeat that Waste of money. The 257 valve is a 308 valve.Waste of money. The 257 valve is a 308 valve. It is way over bore size.

Plus the 257 shoots bullets faster then there accurate already. Specially if you add a 3600 psi tank.

If you want a better poppit I could make you one. Simple cheap fix

interesting. you can make a 257 valve a 308 valve. How?. it would be good if I could get a 308 valve for the 257 texa rifle.

great.

I am a Texan 257 caliber air rifle beginner. how could I make 257 more efficient.

what should be done or bought?.

Upvote 0

I think you are misunderstanding. The .257 and .308 have the same valve as in identical parts. You don't need to do anything to it.I repeat that Waste of money. The 257 valve is a 308 valve.

interesting. you can make a 257 valve a 308 valve. How?. it would be good if I could get a 308 valve for the 257 texa rifle.

great.

I am a Texan 257 caliber air rifle beginner. how could I make 257 more efficient.

what should be done or bought?.

Get a 257420 mold and just shoot it as is until you figure out what you want to change. Theses rifles are made for power not efficiency

Upvote 0

now I understood. 70 grain pellet.I think you are misunderstanding. The .257 and .308 have the same valve as in identical parts. You don't need to do anything to it.

Get a 257420 mold and just shoot it as is until you figure out what you want to change. Theses rifles are made for power not efficiency

257420 mold

that's it then.

An engineer told me that you need to know three things:

3 things you can do that need additional work on PCP airguns: #1 - Increased barrel length #2 - Increased bottle pressure #3 - Improved valve power and efficiency.

how would this be possible and how would you do this yourself.

Upvote 0

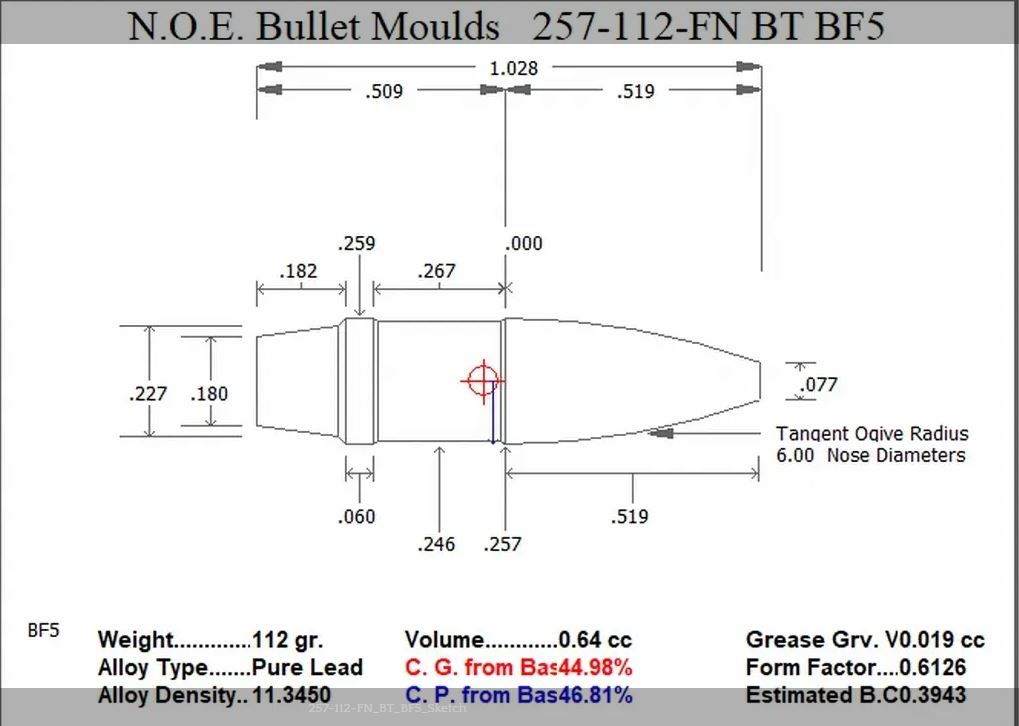

I'm hopeful for you and your results.. If going with heavier slugs like that 112 grain NOE a 1000 fps should be pretty easy to get. I really think the 1-7 twist 257 should be good.

Upvote 0

I was thinking of the bill where 1-7 was 120grain smk, 130grain nosler spitzer. 140 grain smk. 155 grain smk. 6.5= 155 grain 1007.5 fps. if this is true when 140 was 910 fps. 1-7 was 155 grains.I'm hopeful for you and your results.. If going with heavier slugs like that 112 grain NOE a 1000 fps should be pretty easy to get. I really think the 1-7 twist 257 should be good.

that theory strong bottle. I know a bottle that can withstand a maximum of 1020 bar. a good valve for that. where the

( ""valve from?"").

barrel is enough.

Upvote 0

And,I'm hopeful for you and your results.. If going with heavier slugs like that 112 grain NOE a 1000 fps should be pretty easy to get. I really think the 1-7 twist 257 should be good.

what would be the 257 output if the valve was 0.457 caliber?. pressure supply to 257 barrels. bottle max pressure 1020 bar. 14,000 psi = 965 bar. 14,000 psi supply.

how to get the durability of the valve?

Upvote 0

And,

what would be the 257 output if the valve was 0.457 caliber?. pressure supply to 257 barrels. bottle max pressure 1020 bar. 14,000 psi = 965 bar. 14,000 psi supply.

how to get the durability of the valve?

I'm hopeful for you and your results.. If going with heavier slugs like that 112 grain NOE a 1000 fps should be pretty easy to get. I really think the 1-7 twist 257 should be good.

Upvote 0