You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AEA HP Carbine TD/Assassin .25 cal without the moderator not cycling in semi-auto

- Thread starter LLPersonalProtection

- Start date

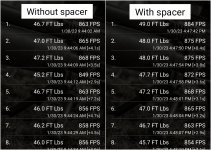

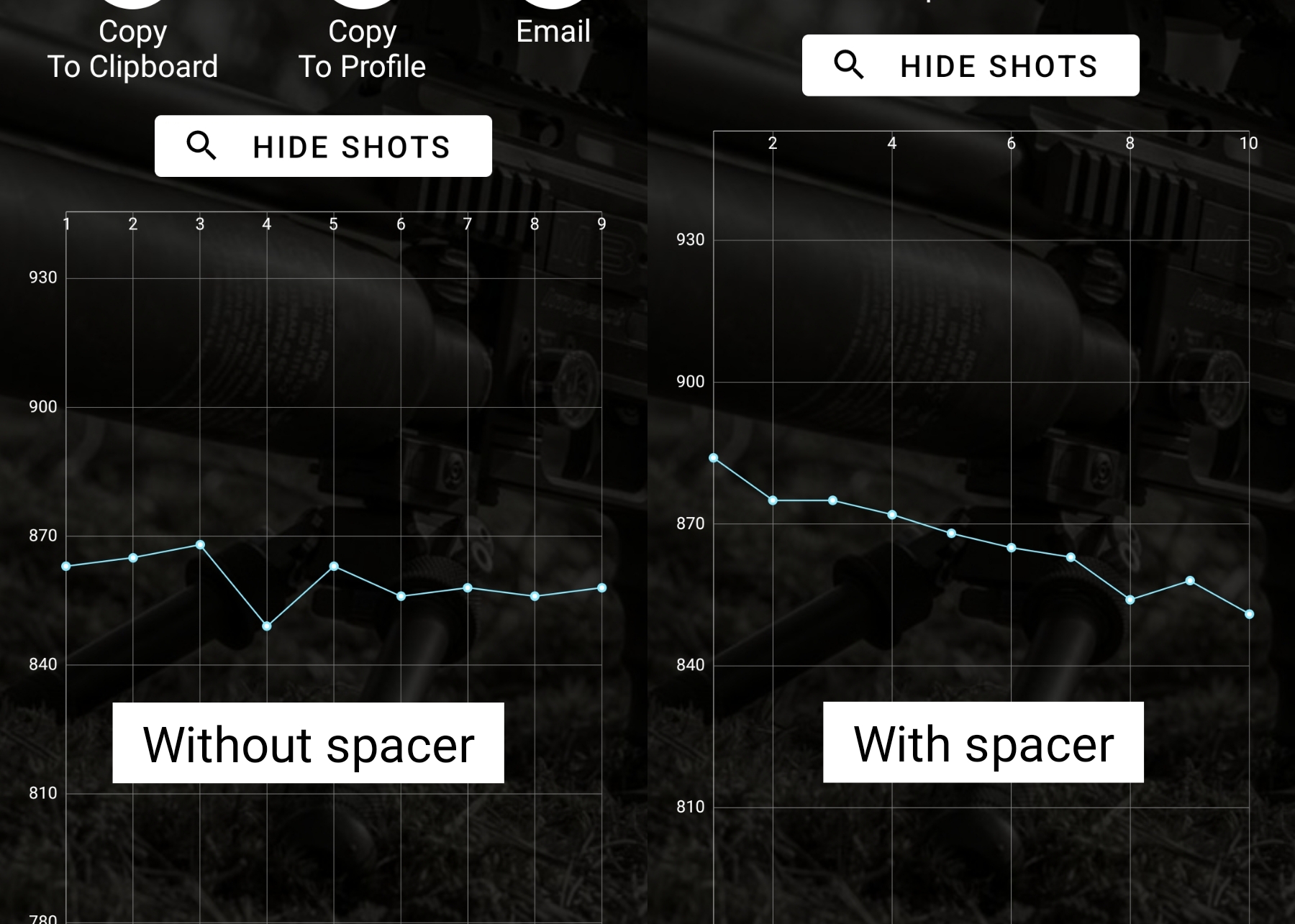

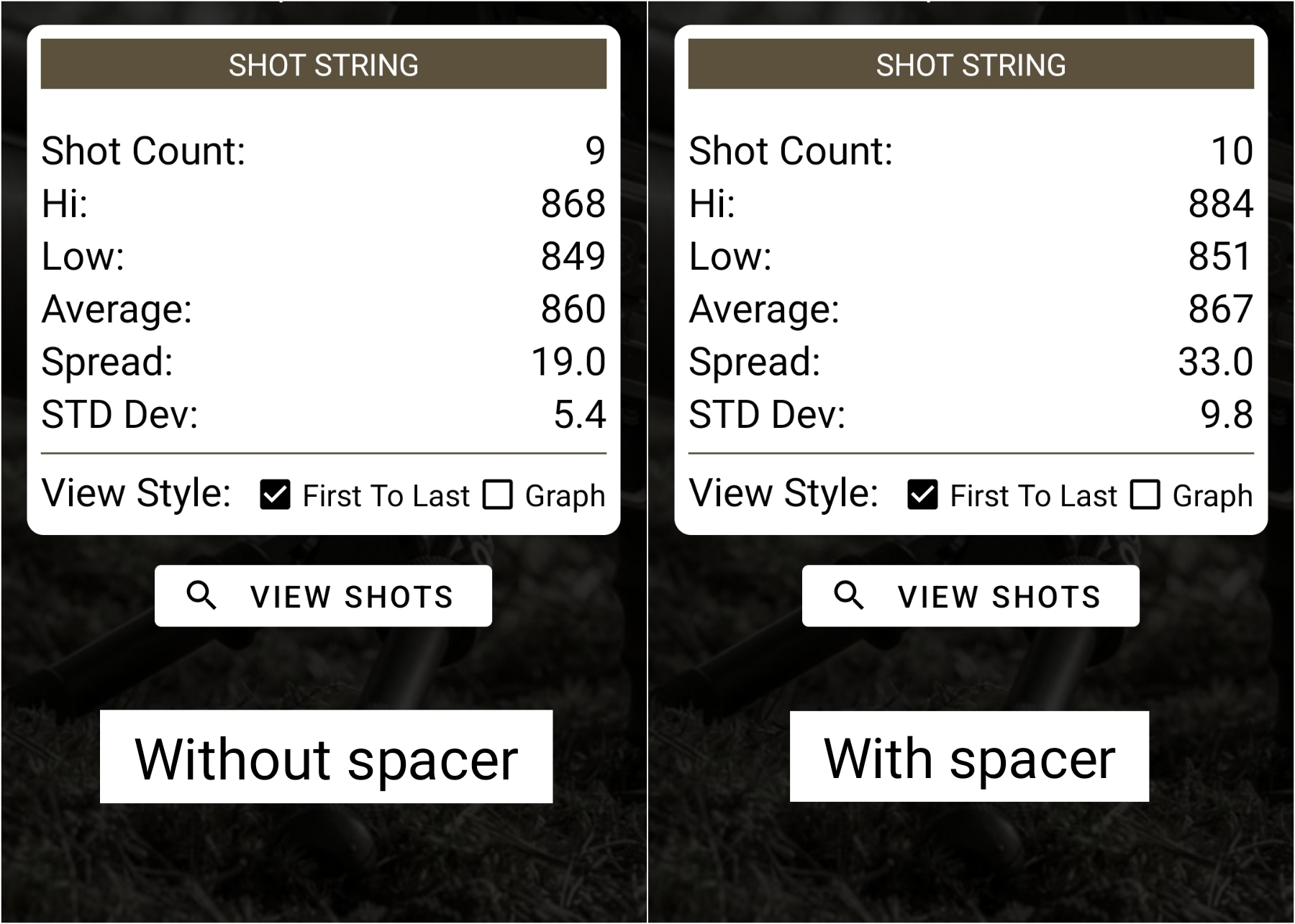

The hammer springs get week. I have mine spaced about 3/8". Velocity on mine dropped about 100 fps a while back. With this spacer its back to where it was 27 g slug at 900 fps. I think you have enough pressure with your setup.

I detuned mine some so it would not cycle so hard. I had it so light that it would not cycle without a pellet in it. Couple months later it became unreliable and didn't sound as strong. When I checked velocity it was down. That is when I realized it needed more hammer spring, I ground down A 5/16 nut and stuck it inside the stock end. Later I made some bushings on the lathe of different widths.

I would try spacers first. I polished the spring guide rod and hammer. Use a good lube and lube the cylinder inside the shroud too. Sorry to lead you astray. Pictures helped me I thought your setup was different. The hole in picture one is a bit over 3/8" looks like that is what yours is from what I can tell.

Here is the sweet spot for me on the cylinder adjustment. You can see about two threads of the rod going past the cylinder. Also this cylinder can get sticky and slow down the cycling. I like running my dry as possible.

View attachment 326729

Ok... Interestingly enough, I pulled out the rear spring and just stretched it out. I tried putting in one of those quarter inch shims and it wouldn't allow me to screw the stock and on all the way so I just left it out this time. I did however, make the small adjustment where there is only two threads showing on the blowback piston and sure asLooks good to me.

No I don't know if it was one or the other or a combination of both however, if it was the spring, it should revert back to where it was in the near future

Upvote 0

D

Deleted member 15252

Guest

Alright ID of the bushing is .220, OD is .340, height is .250. My guide rod diameter measures .215, the hole in the stock ID is .352. So the bushing OD needs to be small enough to fit into the stock hole and bushing ID large enough to allow guide rod to pass through. The guide rod fits into the guide pilot hole on stock end. (Pic 3) Bushing will ride over the guide rod resting on the outside of the guide pilot hole on stock end, spring will ride on top of this bushing. Numbers I'm giving you are not critical but have to be close.

To install the stock you have to have gun UNCOCKED. Guide rod must be in the guide pilot hole and through the bushing or you cannot get the stock back on. Picture four is how the guide rod and spring should look if the hammer is all the way forward. This is what you want.

![PhotoPictureResizer_1674827257645_copy_1376x877[1].jpg PhotoPictureResizer_1674827257645_copy_1376x877[1].jpg](https://www.airgunnation.com/attachments/photopictureresizer_1674827257645_copy_1376x877-1-jpg.326994/)

![PhotoPictureResizer_1674827311197_copy_1451x728[1].jpg PhotoPictureResizer_1674827311197_copy_1451x728[1].jpg](https://www.airgunnation.com/attachments/photopictureresizer_1674827311197_copy_1451x728-1-jpg.326995/)

![PhotoPictureResizer_1674827151289_copy_1022x811[1].jpg PhotoPictureResizer_1674827151289_copy_1022x811[1].jpg](https://www.airgunnation.com/attachments/photopictureresizer_1674827151289_copy_1022x811-1-jpg.326996/)

![PhotoPictureResizer_1674828921764_copy_1612x1209[1].jpg PhotoPictureResizer_1674828921764_copy_1612x1209[1].jpg](https://www.airgunnation.com/attachments/photopictureresizer_1674828921764_copy_1612x1209-1-jpg.327001/)

To install the stock you have to have gun UNCOCKED. Guide rod must be in the guide pilot hole and through the bushing or you cannot get the stock back on. Picture four is how the guide rod and spring should look if the hammer is all the way forward. This is what you want.

Last edited by a moderator:

Upvote 0

Ahhh... I see. I had the bushing fit in the stock, but the ID was just large enough for the smaller Tipp at the end, not for the OD of the entire rod.

Thanks a bunch! I'll report back my findings afterwards LOL

Thanks a bunch! I'll report back my findings afterwards LOL

Upvote 0

UPDATE:

Searched Lowes, Home Depot, & three ACE Hardwares...no spacers lol...so I used and expansion spring. I figured an already compressed metal spring should work also...which it has . I just cut her down to just about 1/4".....these were the immediate findings with a full top off at 3400psi using 28.24gr H&N Baracuda Hunter Extremes. I was able to get the extra 10-15 I was searching for however, looks like on this one test, the stand deviation/consistency took a hit. I will reload/air up and attempt with a couple mags to see if she flattens out a little otherwise, I'm very content with those #s. Thank you for the assistance and the tips

. I just cut her down to just about 1/4".....these were the immediate findings with a full top off at 3400psi using 28.24gr H&N Baracuda Hunter Extremes. I was able to get the extra 10-15 I was searching for however, looks like on this one test, the stand deviation/consistency took a hit. I will reload/air up and attempt with a couple mags to see if she flattens out a little otherwise, I'm very content with those #s. Thank you for the assistance and the tips

Searched Lowes, Home Depot, & three ACE Hardwares...no spacers lol...so I used and expansion spring. I figured an already compressed metal spring should work also...which it has

Attachments

Upvote 0

Do you happen to know what the shroud thread size on you HP TD is? I recently got one of these but the moderator adapter that was sent to me does not fit (I ordered the recommended size). I'm assuming the thread size must be different for the carbon fiber shroud vs the aluminum. Thanks in advance.

Upvote 0

D

Deleted member 15252

Guest

Mine is the aluminum shroud. They should be the same size. Thread size is 30mm diameter 1mm thread.

Upvote 0

I ordered a HP TD Carbine and the DonnyFL adapter from foxairpower and the one I got definitely didn't fit. I emailed him and he said he was going to check on the correct size and get back to me. I figured maybe it was a different size but maybe he sent the wrong one . When I get home tonight I'll meaure the one that was sent. Thanks for the info!

. When I get home tonight I'll meaure the one that was sent. Thanks for the info!

Upvote 0

You making these bushings too?Alright ID of the bushing is .220, OD is .340, height is .250. My guide rod diameter measures .215, the hole in the stock ID is .352. So the bushing OD needs to be small enough to fit into the stock hole and bushing ID large enough to allow guide rod to pass through. The guide rod fits into the guide pilot hole on stock end. (Pic 3) Bushing will ride over the guide rod resting on the outside of the guide pilot hole on stock end, spring will ride on top of this bushing. Numbers I'm giving you are not critical but have to be close.

To install the stock you have to have gun UNCOCKED. Guide rod must be in the guide pilot hole and through the bushing or you cannot get the stock back on. Picture four is how the guide rod and spring should look if the hammer is all the way forward. This is what you want.

View attachment 326994

View attachment 326995

View attachment 326996

View attachment 327001

Upvote 0

D

Deleted member 15252

Guest

Daygo 619

Sent you a PM

Looking at the shot string info above is interesting. On my old spring velocity jumped up and shot count went down. I ordered a new spring and installed and velocity stayed the same with and without spacers. Comparing the length of the spring to the old spring was same length. Wire size though was .8mm thicker on the new spring compared to the old. So I am not sure if they have two strengths of springs for this gun or what.

Sent you a PM

Looking at the shot string info above is interesting. On my old spring velocity jumped up and shot count went down. I ordered a new spring and installed and velocity stayed the same with and without spacers. Comparing the length of the spring to the old spring was same length. Wire size though was .8mm thicker on the new spring compared to the old. So I am not sure if they have two strengths of springs for this gun or what.

Upvote 0

Great info man! Thanks for that.The hammer springs get week. I have mine spaced about 3/8". Velocity on mine dropped about 100 fps a while back. With this spacer its back to where it was 27 g slug at 900 fps. I think you have enough pressure with your setup.

I detuned mine some so it would not cycle so hard. I had it so light that it would not cycle without a pellet in it. Couple months later it became unreliable and didn't sound as strong. When I checked velocity it was down. That is when I realized it needed more hammer spring, I ground down A 5/16 nut and stuck it inside the stock end. Later I made some bushings on the lathe of different widths.

I would try spacers first. I polished the spring guide rod and hammer. Use a good lube and lube the cylinder inside the shroud too. Sorry to lead you astray. Pictures helped me I thought your setup was different. The hole in picture one is a bit over 3/8" looks like that is what yours is from what I can tell.

Here is the sweet spot for me on the cylinder adjustment. You can see about two threads of the rod going past the cylinder. Also this cylinder can get sticky and slow down the cycling. I like running my dry as possible.

View attachment 326729

Can you or someone remind me of the air gauge thread sizes on the HP Carbine?

I'm thinking about a digital gauge upgrade. Thanks

Upvote 0

Hey bud I can't post on classifieds yet but I seen the aea you got... I'm in Cartersville ga please pm me

Upvote 0

So aea carbine uses this to run a donny I wanna run a fatboy 2.0 keep the package even more backpack friendly fatboy is short an can change calibers is this the adapter https://www.thepelletshop.com/products/aea-hp-series-1-2-x-20-adapter-a77

Upvote 0

YesSo aea carbine uses this to run a donny I wanna run a fatboy 2.0 keep the package even more backpack friendly fatboy is short an can change calibers is this the adapter https://www.thepelletshop.com/products/aea-hp-series-1-2-x-20-adapter-a77

Upvote 0