- Apr 25, 2021

- 4,124

- 6,264

- 84

Hello everyone,

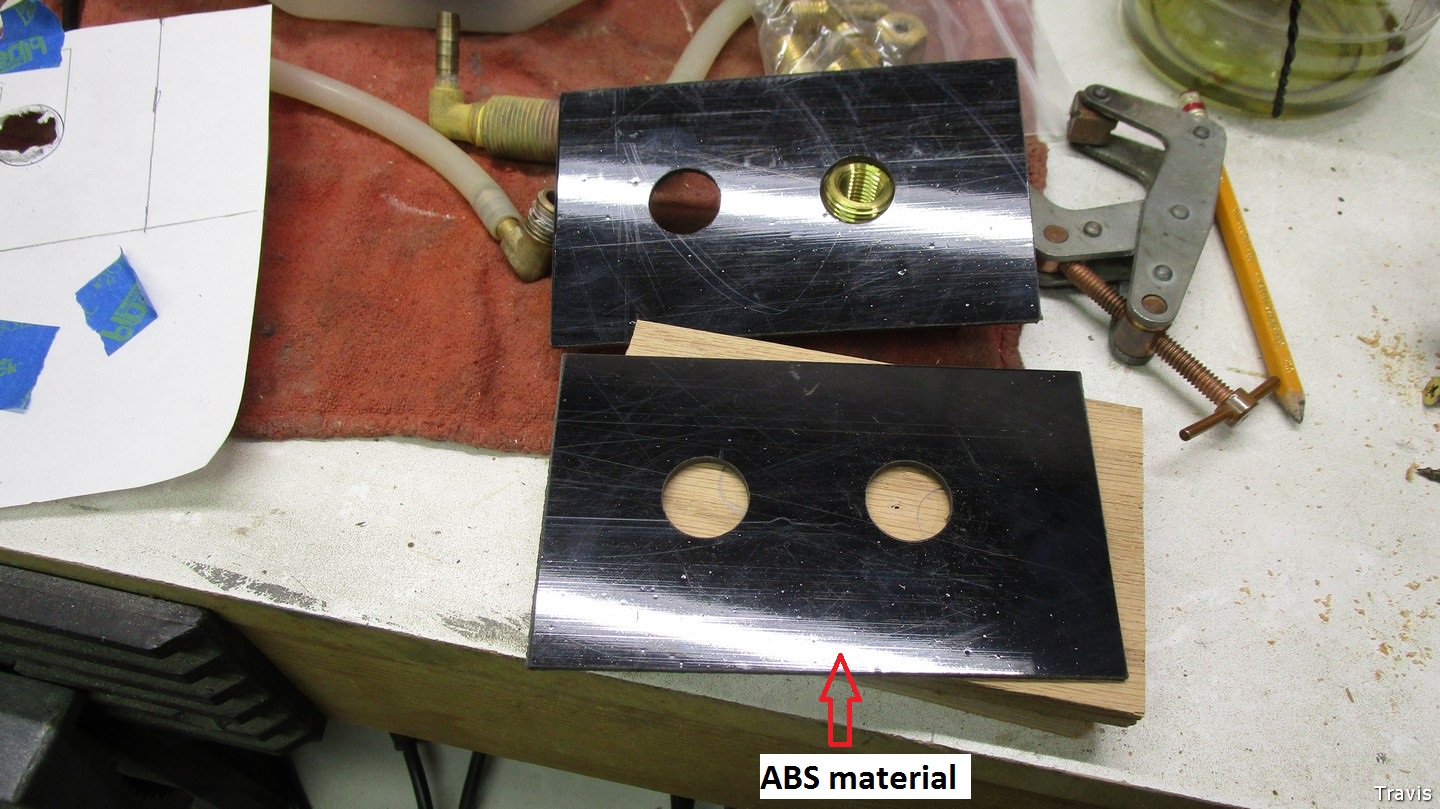

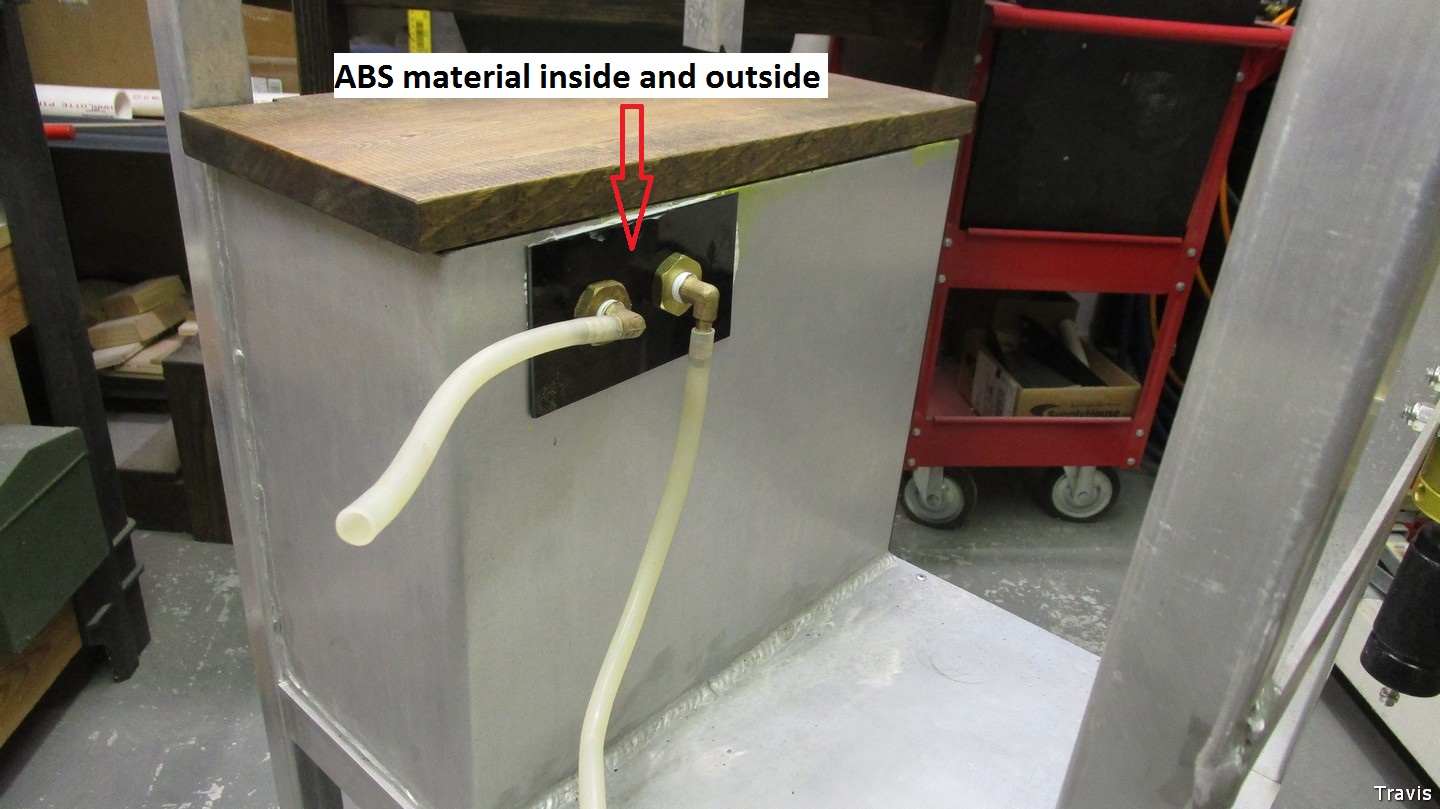

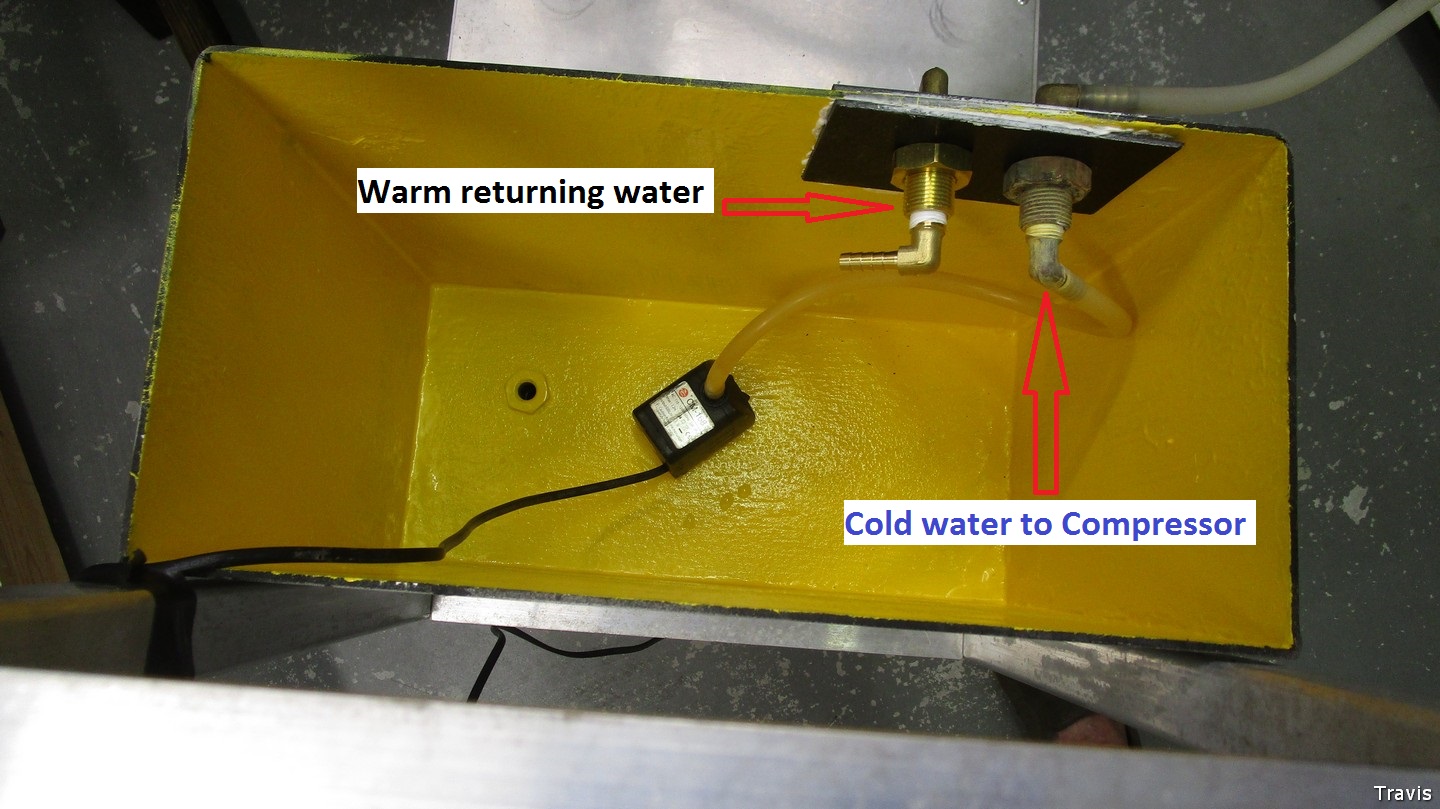

Well I decided to do a rebuild on the Compressor Stand while I had the Yong Heng Compressor out for an oil change. I noticed a very slight erosion around the output side on the brass bulkhead fitting. The problem was my fault for using a stainless star washer which set up some electrolysis. I went ahead and applied 3 coats of Yellow paint to the inside of the 5-gallon water tank for two reasons; 1) help insulate the aluminum plate and 2) to make it much easier to see the treated water in the tank. I also decided to completely isolate the brass bulkhead fittings from the tank. First I oversized the holes in the tank so that the bulkhead fittings could be “centered” in the holes thus isolating them from the aluminum plate. Next I bought some dielectric ABS material ( the black plastic in the photos ) and precisely drilled two .75" holes spaced exactly “center to center” to match the holes in the aluminum. This arrangement gave me almost a 1/8" clearance around the brass from the aluminum. Now the brass bulkhead fittings are not in contact at all with the aluminum tank material. Finally as an added precaution I applied a layer of Silicone to the interior side of the ABS material before attaching both pieces to the tank. I hope the photos make clear this procedure.

Reinstall the water pump, the compressor, the light, the top and all I need now is 4 gallons of distilled water with the water treatment and this baby should be ready to go for another year.

ThomasT

Well I decided to do a rebuild on the Compressor Stand while I had the Yong Heng Compressor out for an oil change. I noticed a very slight erosion around the output side on the brass bulkhead fitting. The problem was my fault for using a stainless star washer which set up some electrolysis. I went ahead and applied 3 coats of Yellow paint to the inside of the 5-gallon water tank for two reasons; 1) help insulate the aluminum plate and 2) to make it much easier to see the treated water in the tank. I also decided to completely isolate the brass bulkhead fittings from the tank. First I oversized the holes in the tank so that the bulkhead fittings could be “centered” in the holes thus isolating them from the aluminum plate. Next I bought some dielectric ABS material ( the black plastic in the photos ) and precisely drilled two .75" holes spaced exactly “center to center” to match the holes in the aluminum. This arrangement gave me almost a 1/8" clearance around the brass from the aluminum. Now the brass bulkhead fittings are not in contact at all with the aluminum tank material. Finally as an added precaution I applied a layer of Silicone to the interior side of the ABS material before attaching both pieces to the tank. I hope the photos make clear this procedure.

Reinstall the water pump, the compressor, the light, the top and all I need now is 4 gallons of distilled water with the water treatment and this baby should be ready to go for another year.

ThomasT