This is a post purely for sharing

It does not involve advertising or trading. I have not officially joined the forum and have already applied and are waiting for Mr. Mike's approval.

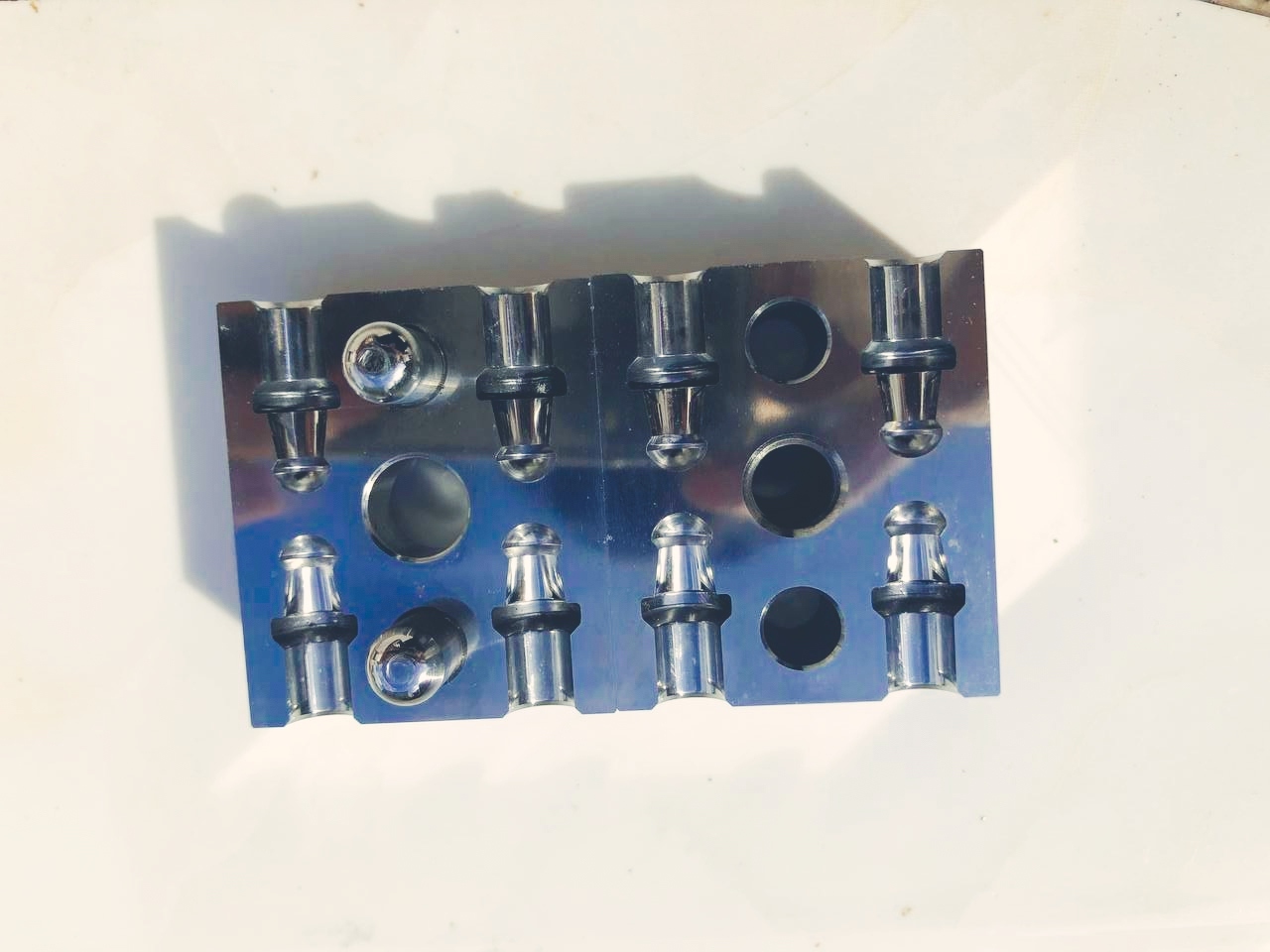

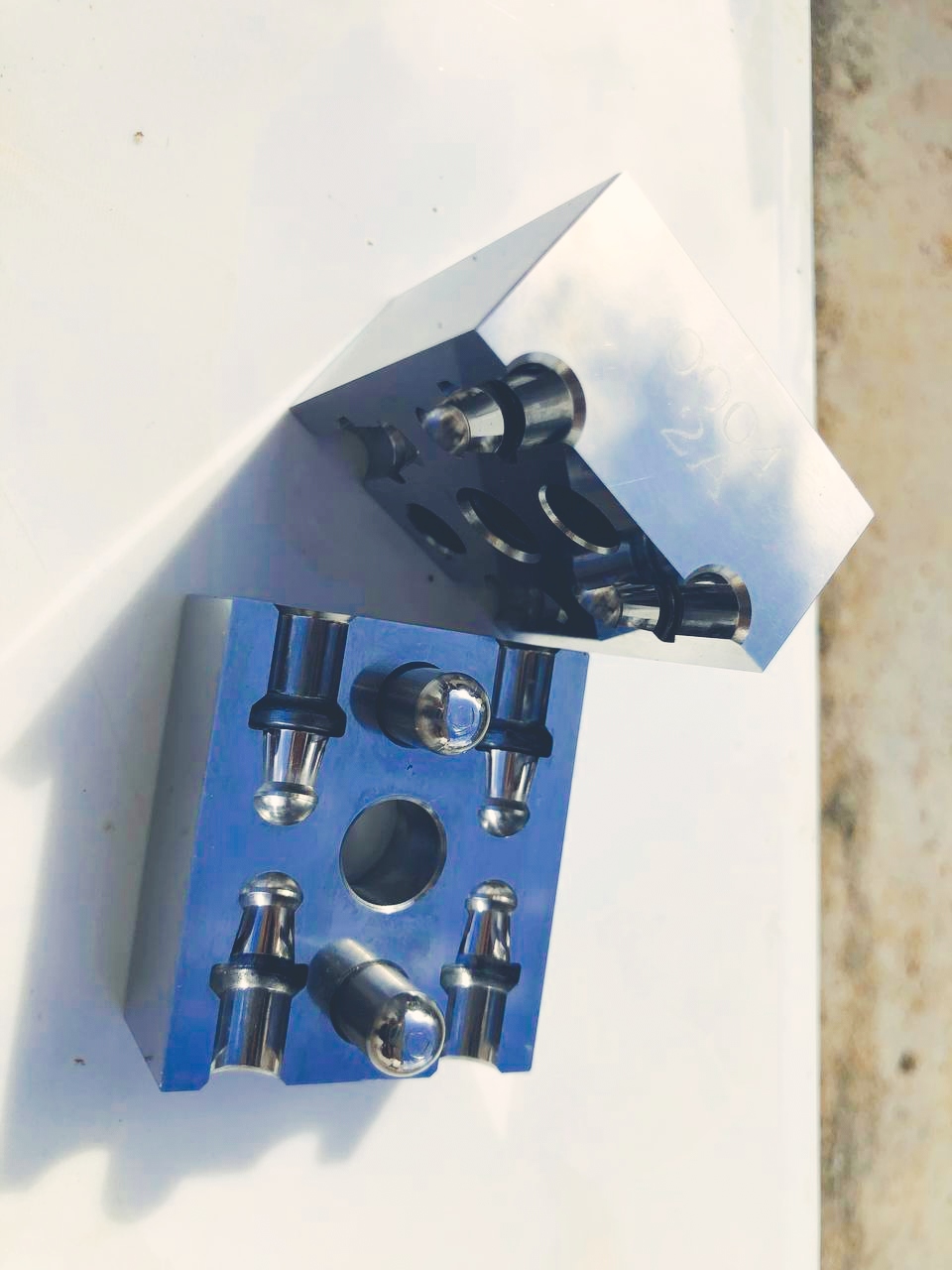

This is an interesting design, the design theme is lightweight, to reduce the weight of the mold

In the end, I successfully reduced it to less than 0.5 kilograms.

This is a semi-automatic mold. You only need to put in the material, flat bottom punch - pointed bottom punch - flat bottom punch, and you can get 4 full and precise pellets. The pellets produced by the four holes have the same weight. of.

The size of pellets is 6.35-6.36, tolerance +0.01MM

The resulting pellets are as bright as a mirror.

The mold uses 440C stainless steel, and the hardness reaches HRC 55 after heat treatment.

This material is difficult to rust, and the mold adopts mirror technology. The final effect is as bright as a mirror

This mold requires the use of: Mirror surface grinder-ordinary CNC-slow wire cutting-processed by high-precision Makino IQ500

It takes a week to complete the entire process to produce a high-quality pellets mold. This mold has no service life and can be used almost for a lifetime, provided you use it correctly.

The lead material has been stored for too long, and the lead made in China has no anti-corrosion design, causing the lead to turn black. In fact, if you use new lead, the pellets will be the same as the mirror. You can look at the first pellets on the left. The tail skirt part is the real effect, just like a mirror.

It does not involve advertising or trading. I have not officially joined the forum and have already applied and are waiting for Mr. Mike's approval.

This is an interesting design, the design theme is lightweight, to reduce the weight of the mold

In the end, I successfully reduced it to less than 0.5 kilograms.

This is a semi-automatic mold. You only need to put in the material, flat bottom punch - pointed bottom punch - flat bottom punch, and you can get 4 full and precise pellets. The pellets produced by the four holes have the same weight. of.

The size of pellets is 6.35-6.36, tolerance +0.01MM

The resulting pellets are as bright as a mirror.

The mold uses 440C stainless steel, and the hardness reaches HRC 55 after heat treatment.

This material is difficult to rust, and the mold adopts mirror technology. The final effect is as bright as a mirror

This mold requires the use of: Mirror surface grinder-ordinary CNC-slow wire cutting-processed by high-precision Makino IQ500

It takes a week to complete the entire process to produce a high-quality pellets mold. This mold has no service life and can be used almost for a lifetime, provided you use it correctly.

The lead material has been stored for too long, and the lead made in China has no anti-corrosion design, causing the lead to turn black. In fact, if you use new lead, the pellets will be the same as the mirror. You can look at the first pellets on the left. The tail skirt part is the real effect, just like a mirror.