So I received my CS4 on 19 Feb 2024. Took the case apart to install an hour meter (which didn't work like I wanted it to, so ordered a different one).

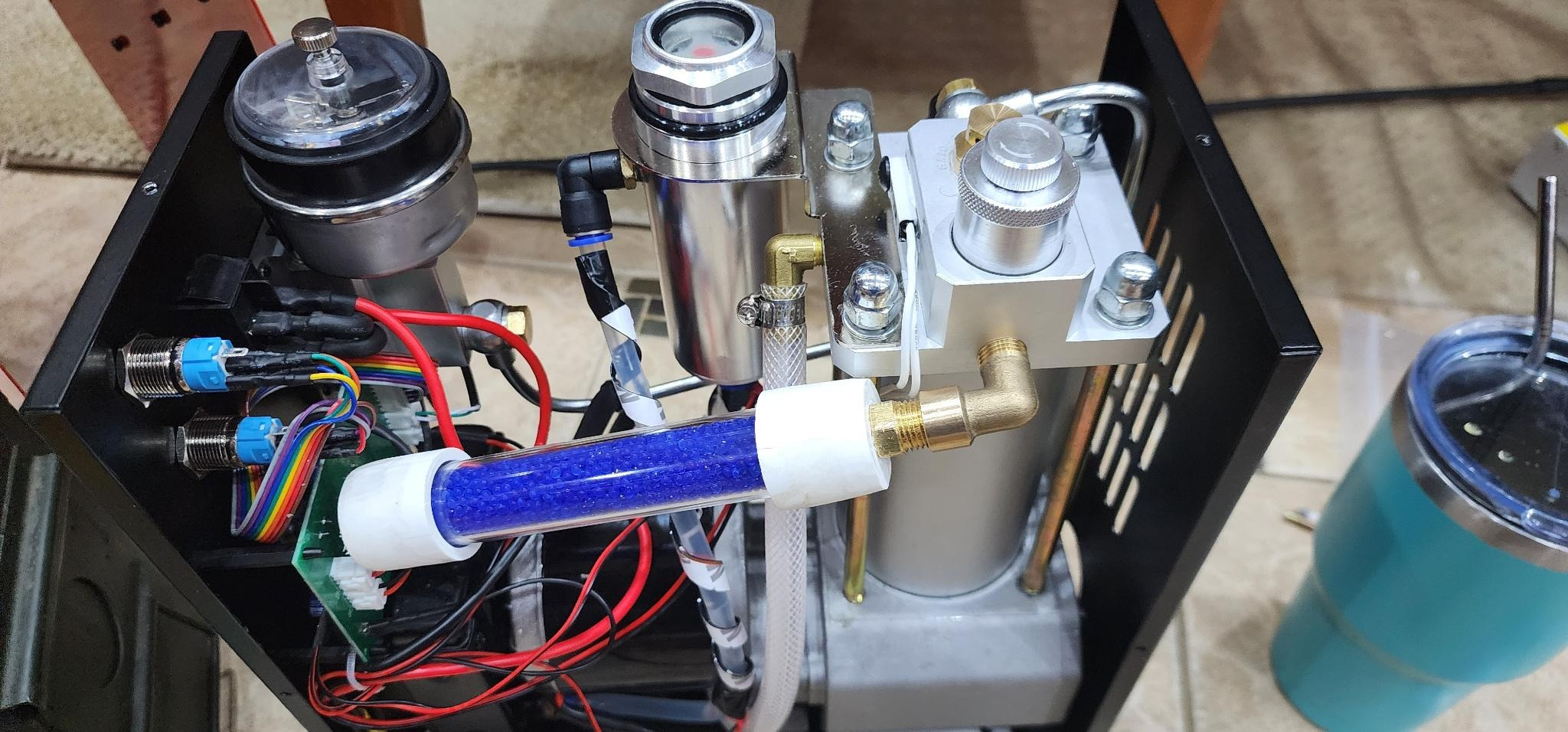

Removed the small pre-filter and installed my homemade one with color-changing silica beads in it. (Two 3/4" PVC caps, tube wrapped with electrical tape to make a snug fit. Intake end has holes drilled in it, output end has a 3/8" brass pipe fitting to mate with the brass elbow into the compressor head).

Had some rusty water inside the bag when it arrived. No large debris in the water tank, but I flushed it about five times with tap water until it ran clear (was a little murky at first). Then put some Dawn dish soap in the reservoir and ran it for a couple of minutes, then began flushing it. After several fill/run/flush cycles, it was running clear. Then I purged the system completely of water, and finished by filling it with 250 ml of distilled water.

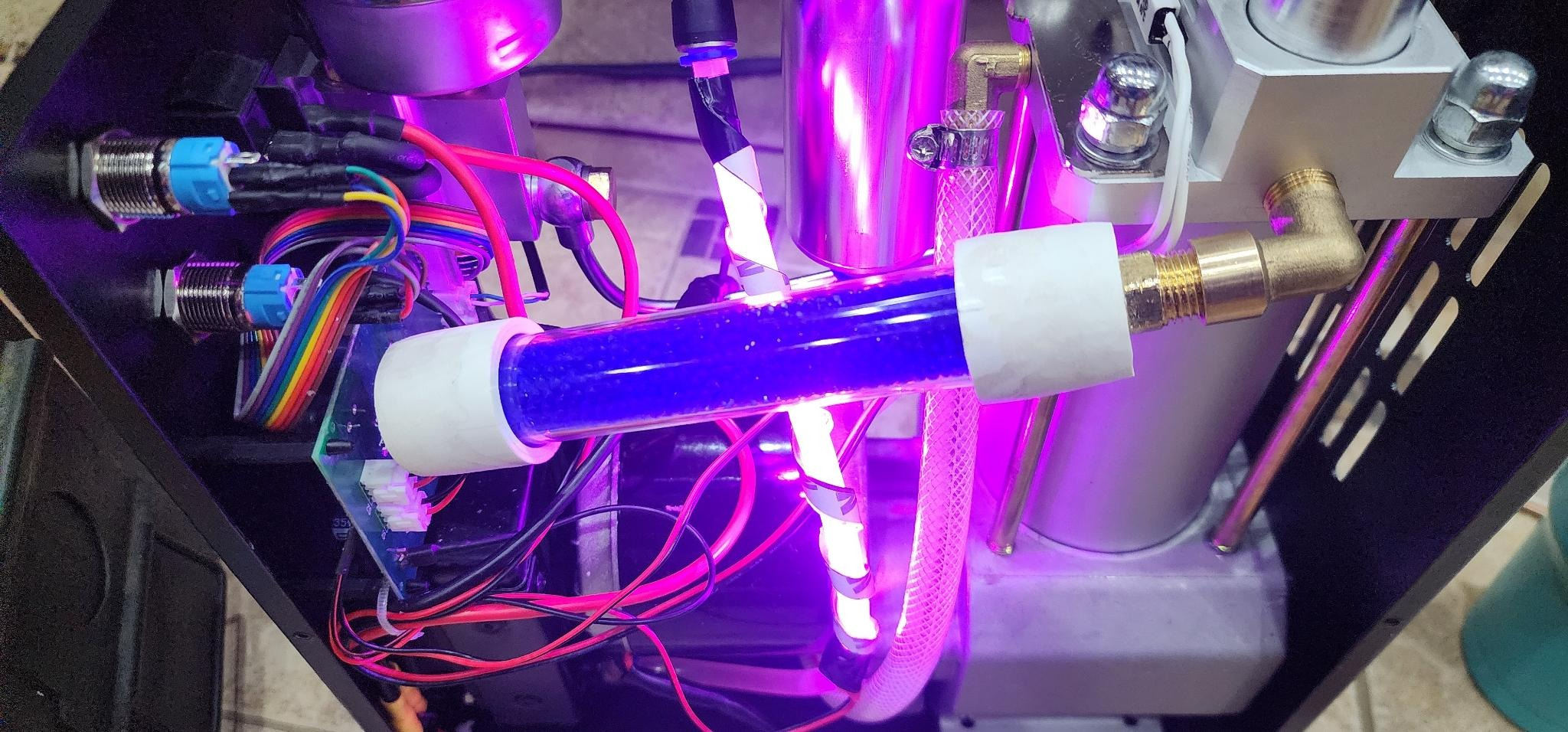

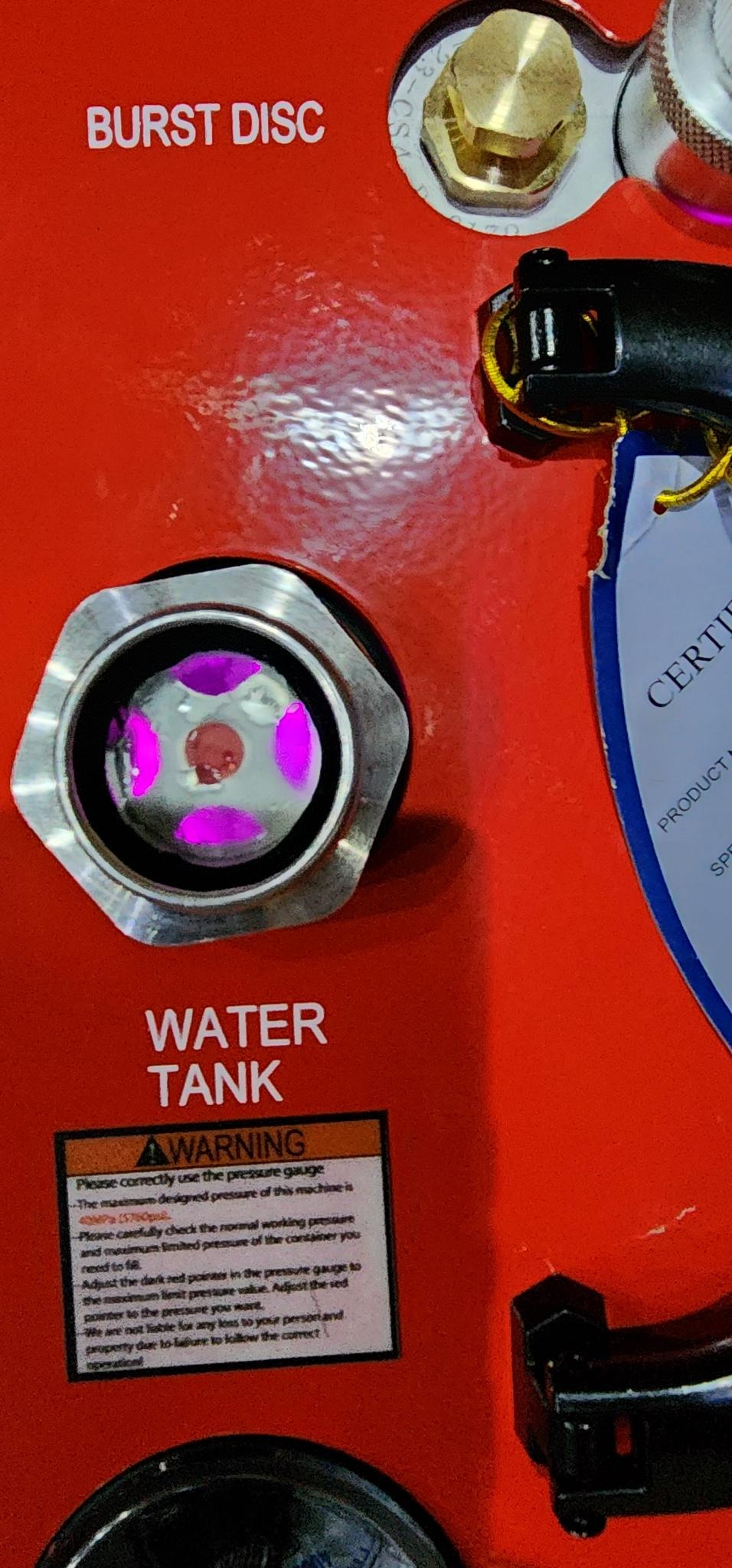

Connected some LED strips to the coolant hoses to make the water flow easy to see when running. Soldered them to the pump contacts so that they come on when the power switch is switched on.

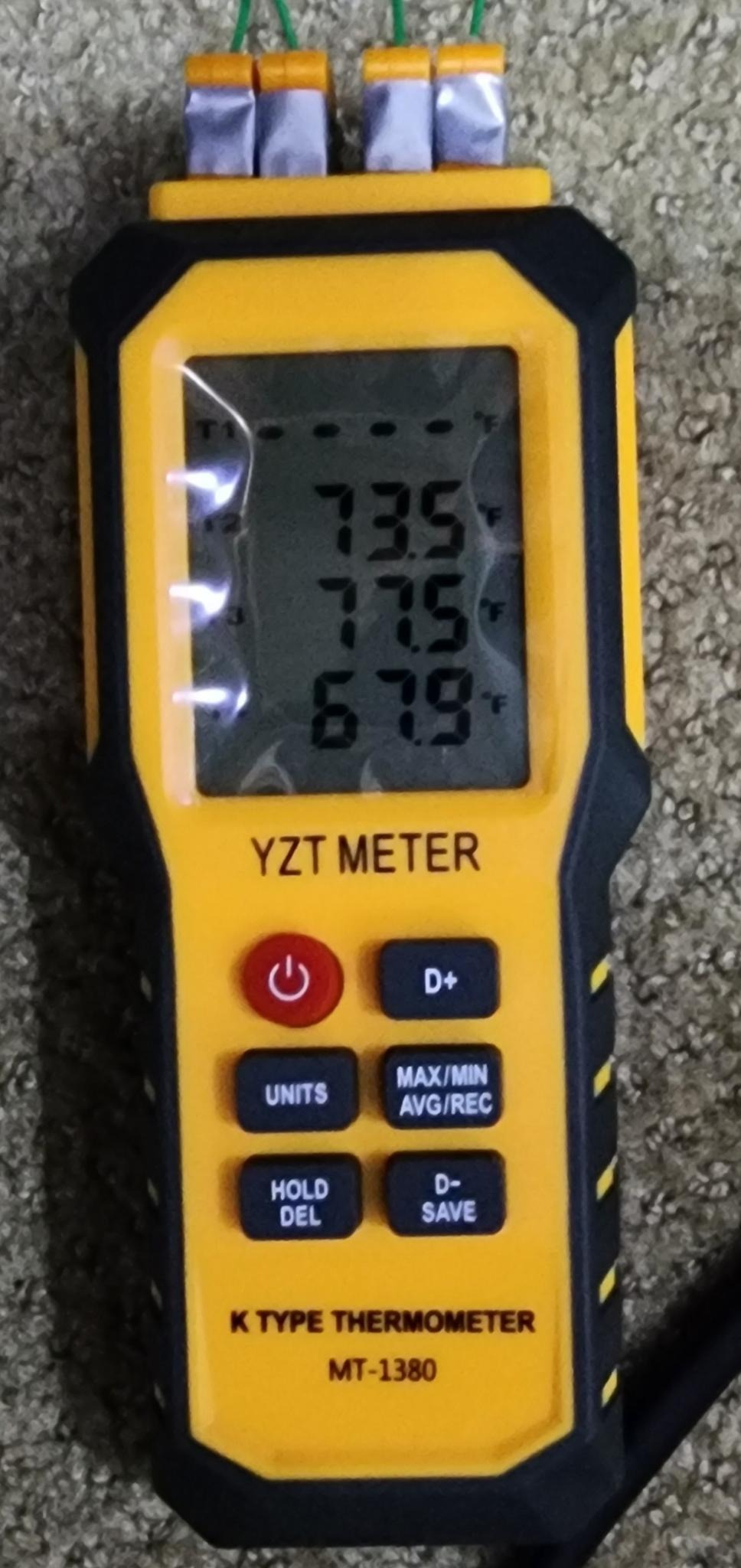

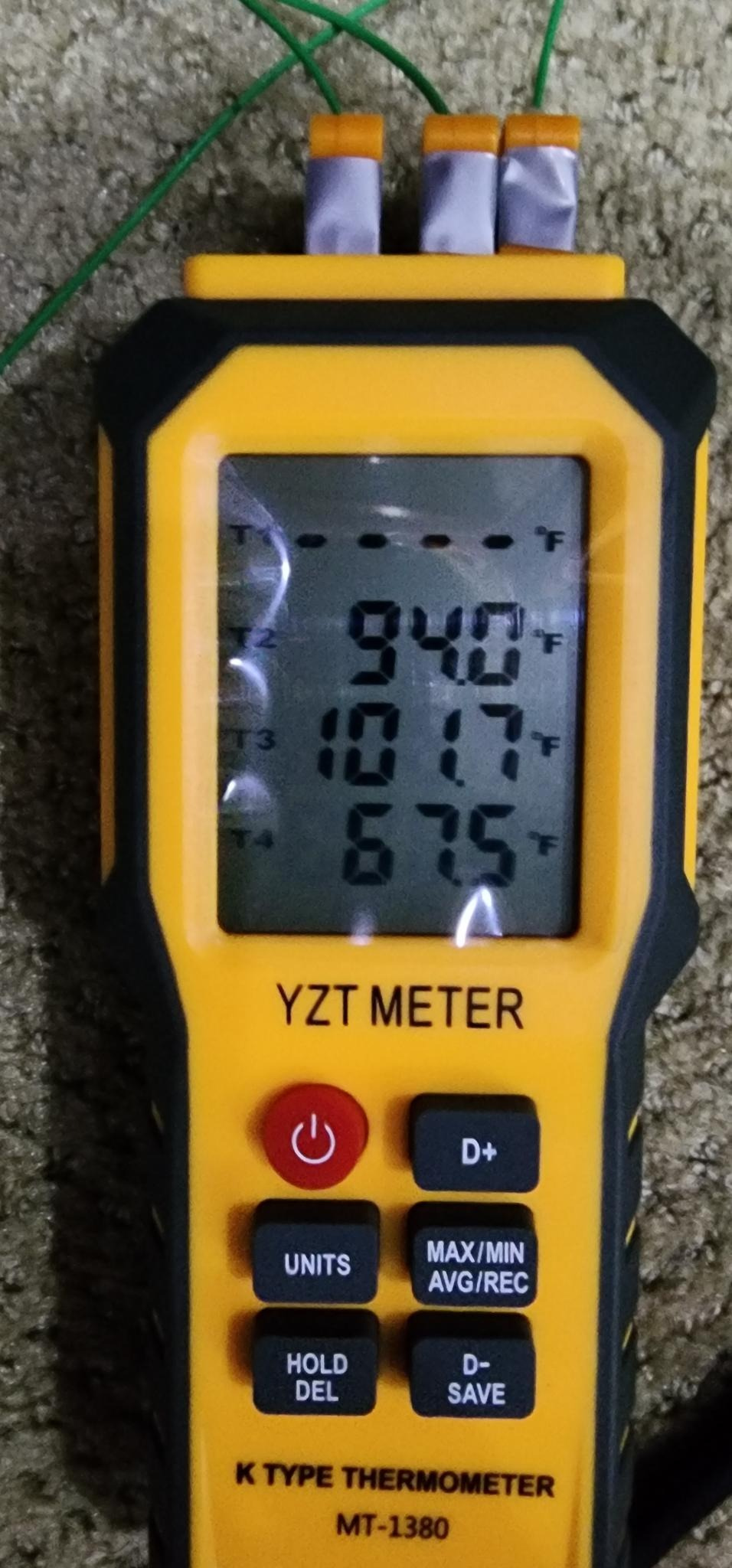

Also added a 4-sensor temperature logger, but one sensor (to the motor) is faulty. Waiting on the seller to get back to me on a replacement. Have the sensors on the Head, Coolant tank, Motor, and Ambient air for tracking purposes. (Temps are - MHCA - Motor, Head of cylinder, Coolant tank, Ambient)

(Start of the 2-hour break-in run)

(Temps after 30 minutes)

Currently running the compressor for two hours with no load, though I saw nothing about that in the owner's manual, only saw it here on AGN. Where did this info come from?

Sadly, mine is one of the non-fluted cylinders. Darn the bad luck!

Parts:

Hour meter #1: (returned because it is too large and the backlight won't come on when the power switch is turned on) - https://www.amazon.com/gp/product/B0C539D7R8

Replaced with this one. Smaller footprint, allowed me to install it in the back of the lower case, as opposed to the top cover, which would require disconnecting wires every time I opened the case:

Hour meter #2: https://www.amazon.com/dp/B0C2XZ3SYV

Plastic tube for pre-filter: https://www.amazon.com/dp/B08ZM5BCQJ

Silica for pre-filter: https://www.amazon.com/dp/B09QFJQQ7Q

Big air filter: https://www.amazon.com/dp/B0BBM4BB84

Small air filter: https://www.amazon.com/dp/B07M8KTS9B

Temperature logger: https://www.amazon.com/dp/B0C39TKV4X

LED strips: https://www.amazon.com/dp/B014V4RO2W

Removed the small pre-filter and installed my homemade one with color-changing silica beads in it. (Two 3/4" PVC caps, tube wrapped with electrical tape to make a snug fit. Intake end has holes drilled in it, output end has a 3/8" brass pipe fitting to mate with the brass elbow into the compressor head).

Had some rusty water inside the bag when it arrived. No large debris in the water tank, but I flushed it about five times with tap water until it ran clear (was a little murky at first). Then put some Dawn dish soap in the reservoir and ran it for a couple of minutes, then began flushing it. After several fill/run/flush cycles, it was running clear. Then I purged the system completely of water, and finished by filling it with 250 ml of distilled water.

Connected some LED strips to the coolant hoses to make the water flow easy to see when running. Soldered them to the pump contacts so that they come on when the power switch is switched on.

Also added a 4-sensor temperature logger, but one sensor (to the motor) is faulty. Waiting on the seller to get back to me on a replacement. Have the sensors on the Head, Coolant tank, Motor, and Ambient air for tracking purposes. (Temps are - MHCA - Motor, Head of cylinder, Coolant tank, Ambient)

(Start of the 2-hour break-in run)

(Temps after 30 minutes)

Currently running the compressor for two hours with no load, though I saw nothing about that in the owner's manual, only saw it here on AGN. Where did this info come from?

Sadly, mine is one of the non-fluted cylinders. Darn the bad luck!

Parts:

Hour meter #1: (returned because it is too large and the backlight won't come on when the power switch is turned on) - https://www.amazon.com/gp/product/B0C539D7R8

Replaced with this one. Smaller footprint, allowed me to install it in the back of the lower case, as opposed to the top cover, which would require disconnecting wires every time I opened the case:

Hour meter #2: https://www.amazon.com/dp/B0C2XZ3SYV

Plastic tube for pre-filter: https://www.amazon.com/dp/B08ZM5BCQJ

Silica for pre-filter: https://www.amazon.com/dp/B09QFJQQ7Q

Big air filter: https://www.amazon.com/dp/B0BBM4BB84

Small air filter: https://www.amazon.com/dp/B07M8KTS9B

Temperature logger: https://www.amazon.com/dp/B0C39TKV4X

LED strips: https://www.amazon.com/dp/B014V4RO2W

Last edited: