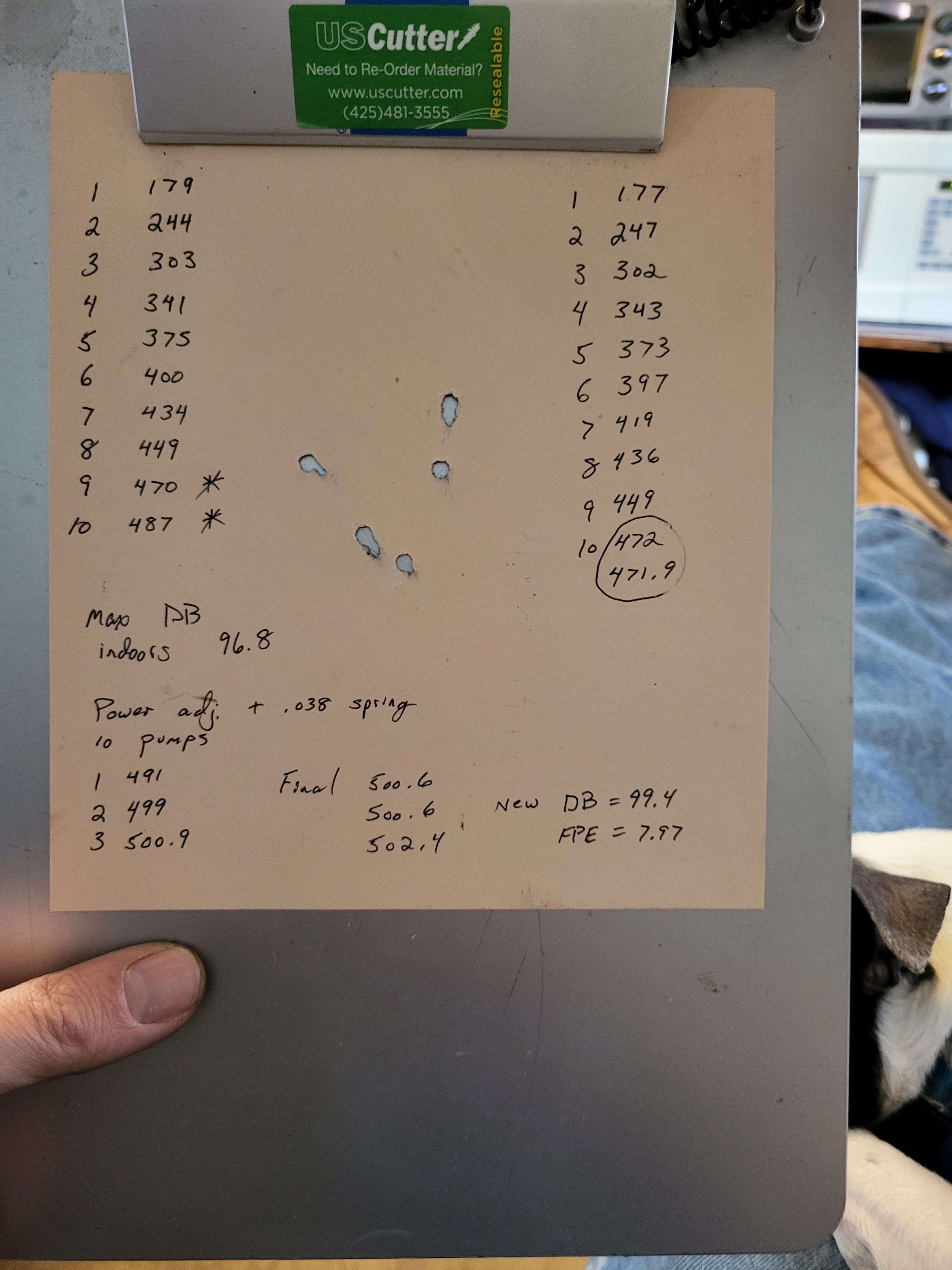

The stock configuration we all know. The numbers of the left column are completely stock right out of the box. The right column is after adding a flow through bolt. Makes no difference in fps. The slight drop I would attribute to having just oiled everything prior to the left column and may have gotten slightly more from the pump cup. The bottom numbers are after adding a hammer spring adjuster and .038 spring. Each number 1-10 is that many pumps for each reading. You can also see a slight jump in the db rating.  after adding the steel breech, and enlarging the transfer port it gained about 4 fps. Not a hard mod to do with a little effort.

after adding the steel breech, and enlarging the transfer port it gained about 4 fps. Not a hard mod to do with a little effort.

you will need to drills. 1 to clamp the port in and the other to drill it out. The bit must be freshly sharp.

you will need to drills. 1 to clamp the port in and the other to drill it out. The bit must be freshly sharp.

The hammer spring adjuster is made from the original cap, and a bolt from the hardware. This 1 is a bit more challenging to make if you are me and don't have a lathe.

you will also need that shim, or shorten the existing mounting bolts at back to be able to turn the adjuster freely.

you will also need that shim, or shorten the existing mounting bolts at back to be able to turn the adjuster freely.

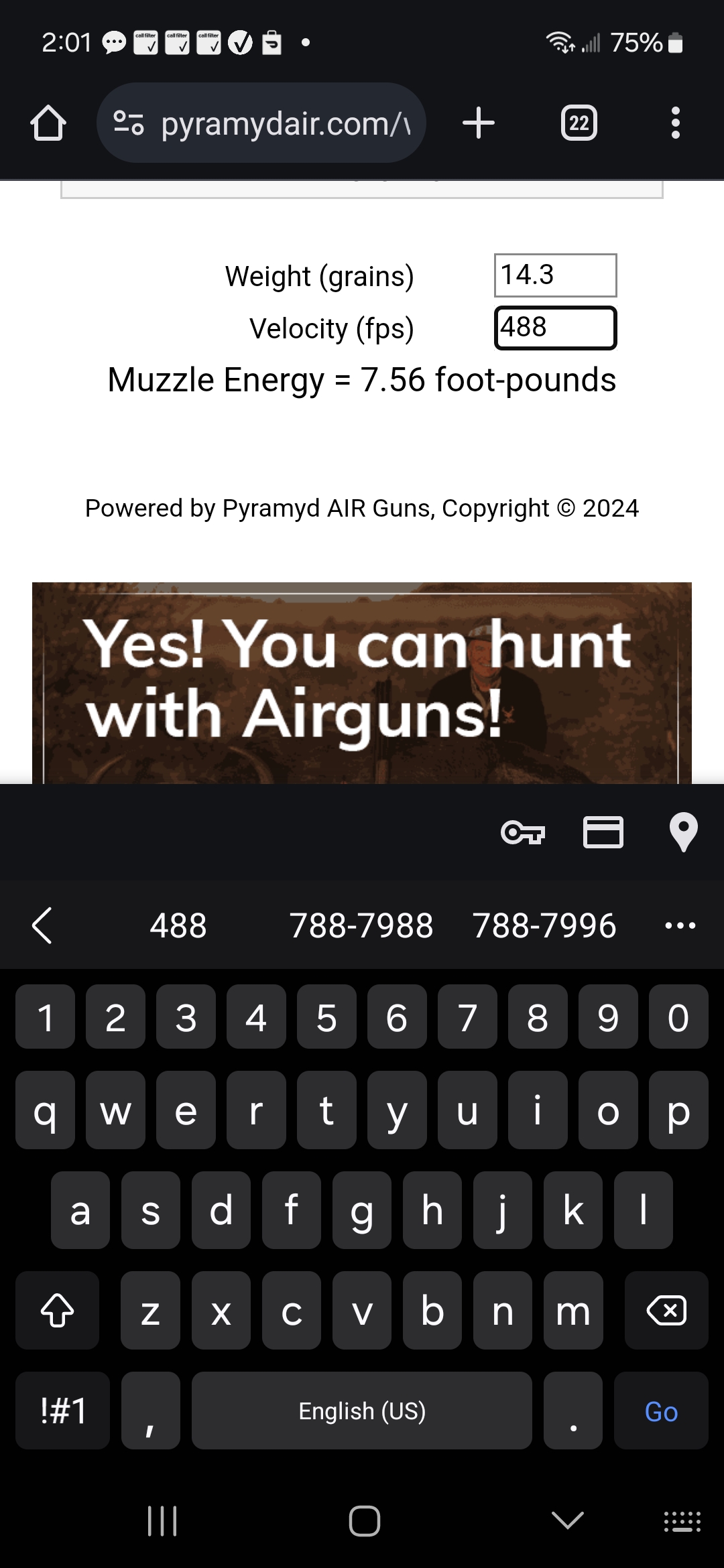

I added a flat top valve, with adjustable piston. Also added a bearing inside the valve to take up space and increase pressure with each stroke. While the gun was apart, I swapped out the barrel band for 1 with a 1/2-20 thread made from aluminum. Has 3 grub screws to secure the barrel, and also allows for centering so you don't get any pellet clipping on the way out. I did have to chase the threads due to poor quality control, thank you China. Zero poi shift on or off. Now with reduced air volume, and silencer it is under 93 db. Also more weight forward and balances better while aiming with the red dot. It's quieter and almost at the same fps as before but with 8 pumps instead of 10. All fps numbers taken with cphp ammo.

It's quieter and almost at the same fps as before but with 8 pumps instead of 10. All fps numbers taken with cphp ammo. putting this over factory fps specs of 460, and doing it with less pumping, and less noise.

putting this over factory fps specs of 460, and doing it with less pumping, and less noise.

Feels like win to me. Specifically designed with sparrow control in mind. Should be more than enough.

The hammer spring adjuster is made from the original cap, and a bolt from the hardware. This 1 is a bit more challenging to make if you are me and don't have a lathe.

I added a flat top valve, with adjustable piston. Also added a bearing inside the valve to take up space and increase pressure with each stroke. While the gun was apart, I swapped out the barrel band for 1 with a 1/2-20 thread made from aluminum. Has 3 grub screws to secure the barrel, and also allows for centering so you don't get any pellet clipping on the way out. I did have to chase the threads due to poor quality control, thank you China. Zero poi shift on or off. Now with reduced air volume, and silencer it is under 93 db. Also more weight forward and balances better while aiming with the red dot.

Feels like win to me. Specifically designed with sparrow control in mind. Should be more than enough.