I am very much ready (in my mind) to start a heavy porting upgrade but I want to make sure that I have spare parts in my drawers.

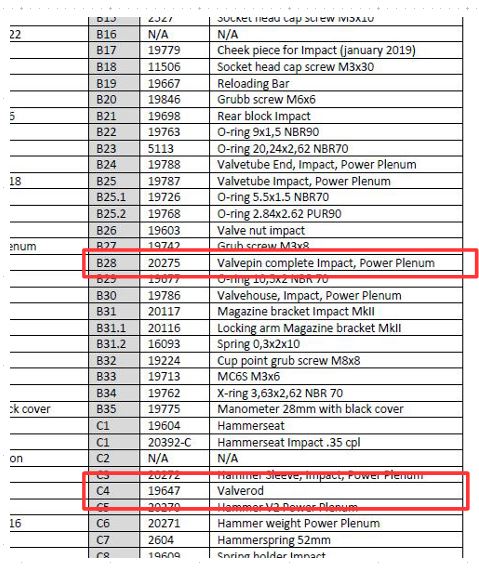

I have a full Impact oring kit in NBR90 from oringsandmore, only missing this one on the vale pin end, What is this oring size not listed in the BOM?

The other thing I am finding interesting, we are closing the 2020 soon and the Impact pdf BOM (revision 20.05) is still creating a mess wherever I go.

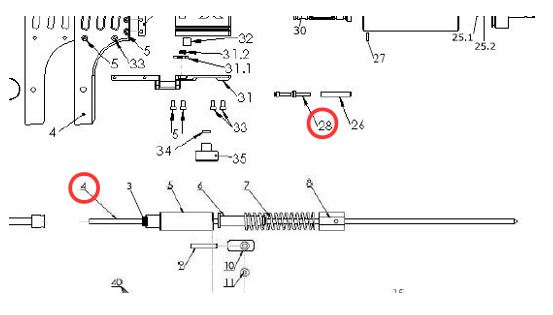

Lets take a look for example this valve seal. I just want to make a new peek poppet for a bigger port, really doesn't matter if I could get a pin only or the entire rod kit.

PN 20275 which is as per FX pdf the B28 the valve pin only, but the europeairguns ( Price: 35.75 € ) and bagnallandkirkwood ( £47.93 ) showing the same PN as an entire rod kit.

Also I would need a oringsandmore PN for the green oring inside PP, could that be the same NBR70 or 90 or really must be PUR90?

I have a full Impact oring kit in NBR90 from oringsandmore, only missing this one on the vale pin end, What is this oring size not listed in the BOM?

The other thing I am finding interesting, we are closing the 2020 soon and the Impact pdf BOM (revision 20.05) is still creating a mess wherever I go.

Lets take a look for example this valve seal. I just want to make a new peek poppet for a bigger port, really doesn't matter if I could get a pin only or the entire rod kit.

PN 20275 which is as per FX pdf the B28 the valve pin only, but the europeairguns ( Price: 35.75 € ) and bagnallandkirkwood ( £47.93 ) showing the same PN as an entire rod kit.

Also I would need a oringsandmore PN for the green oring inside PP, could that be the same NBR70 or 90 or really must be PUR90?