Hello All,

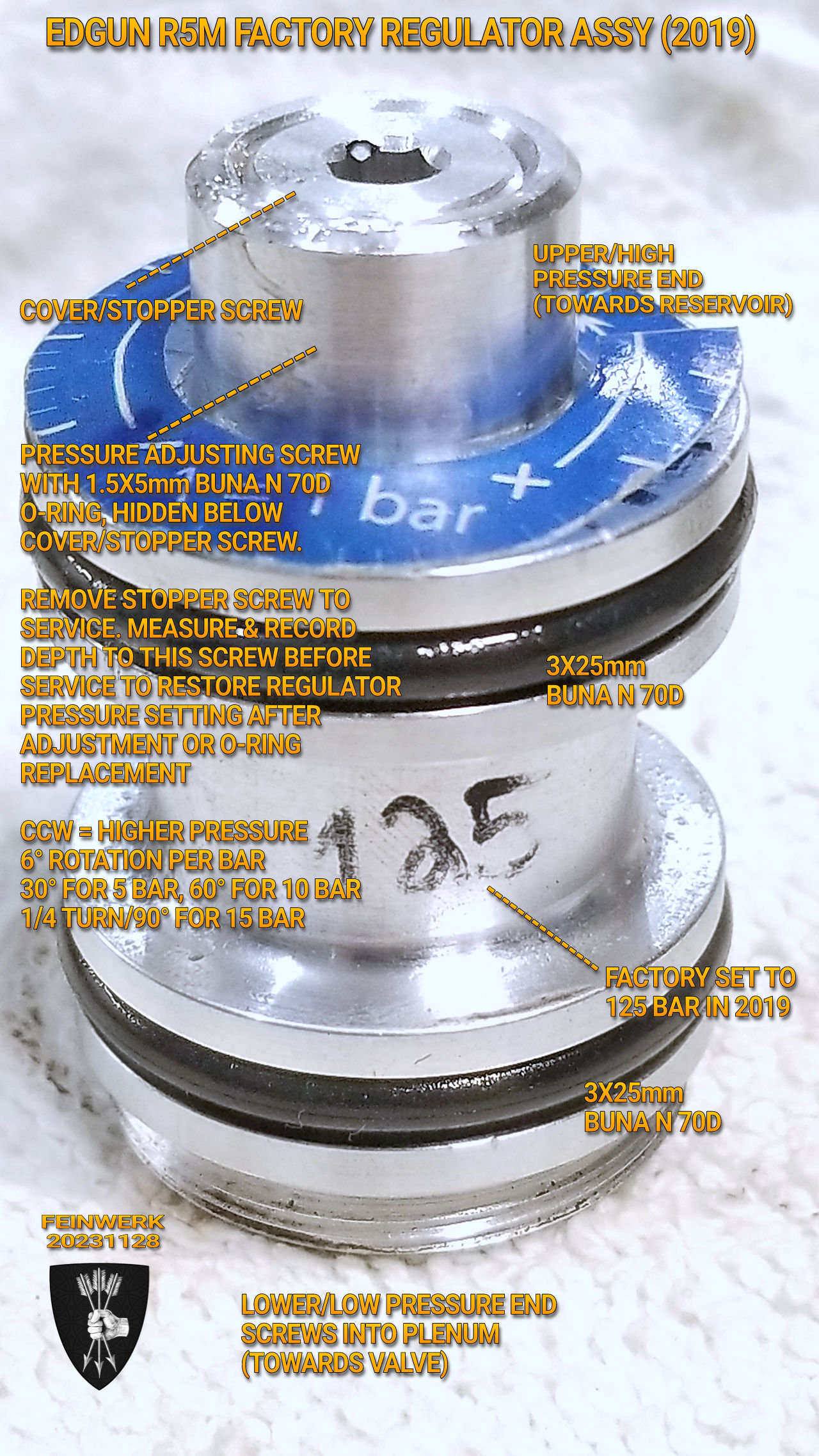

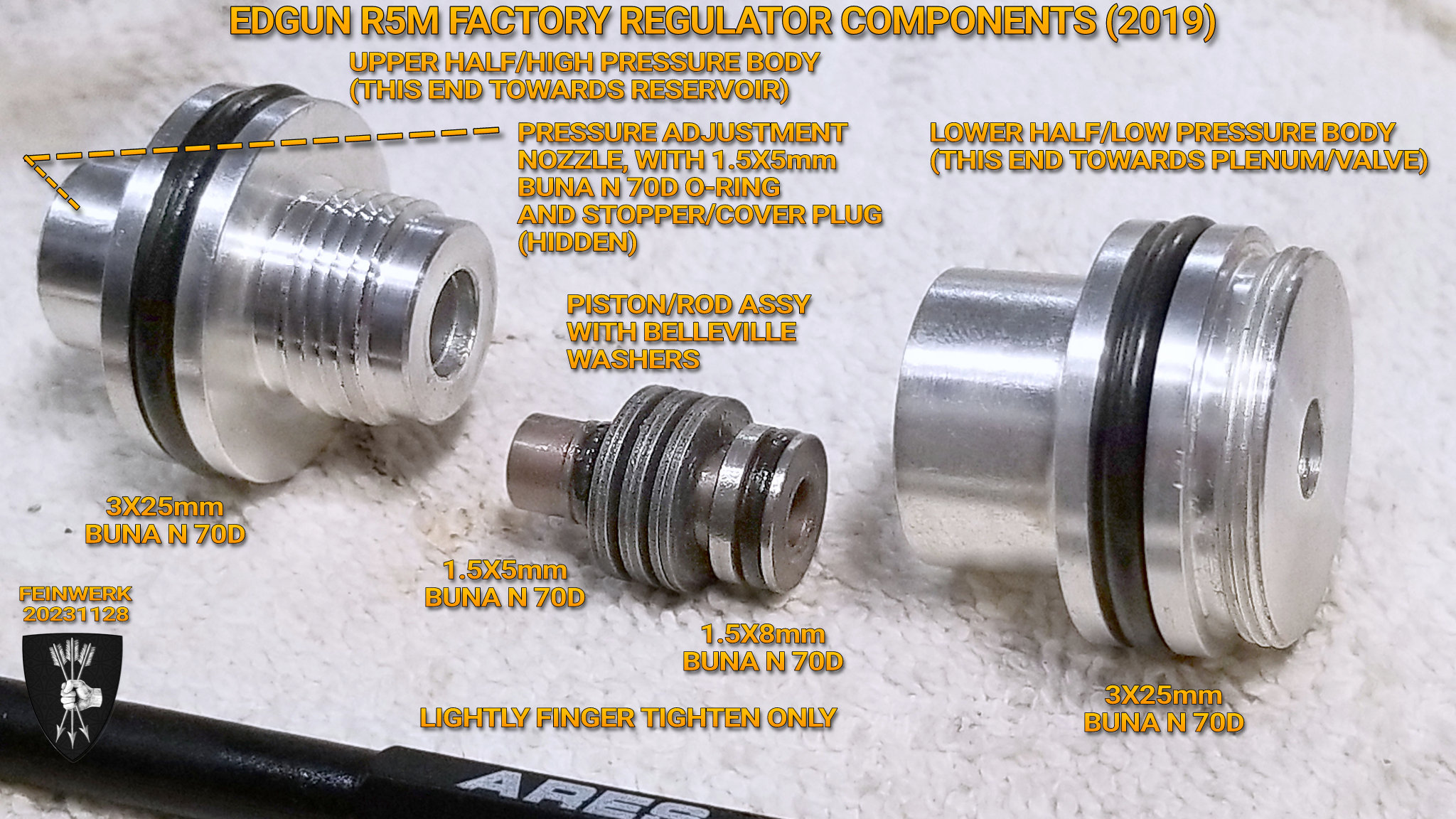

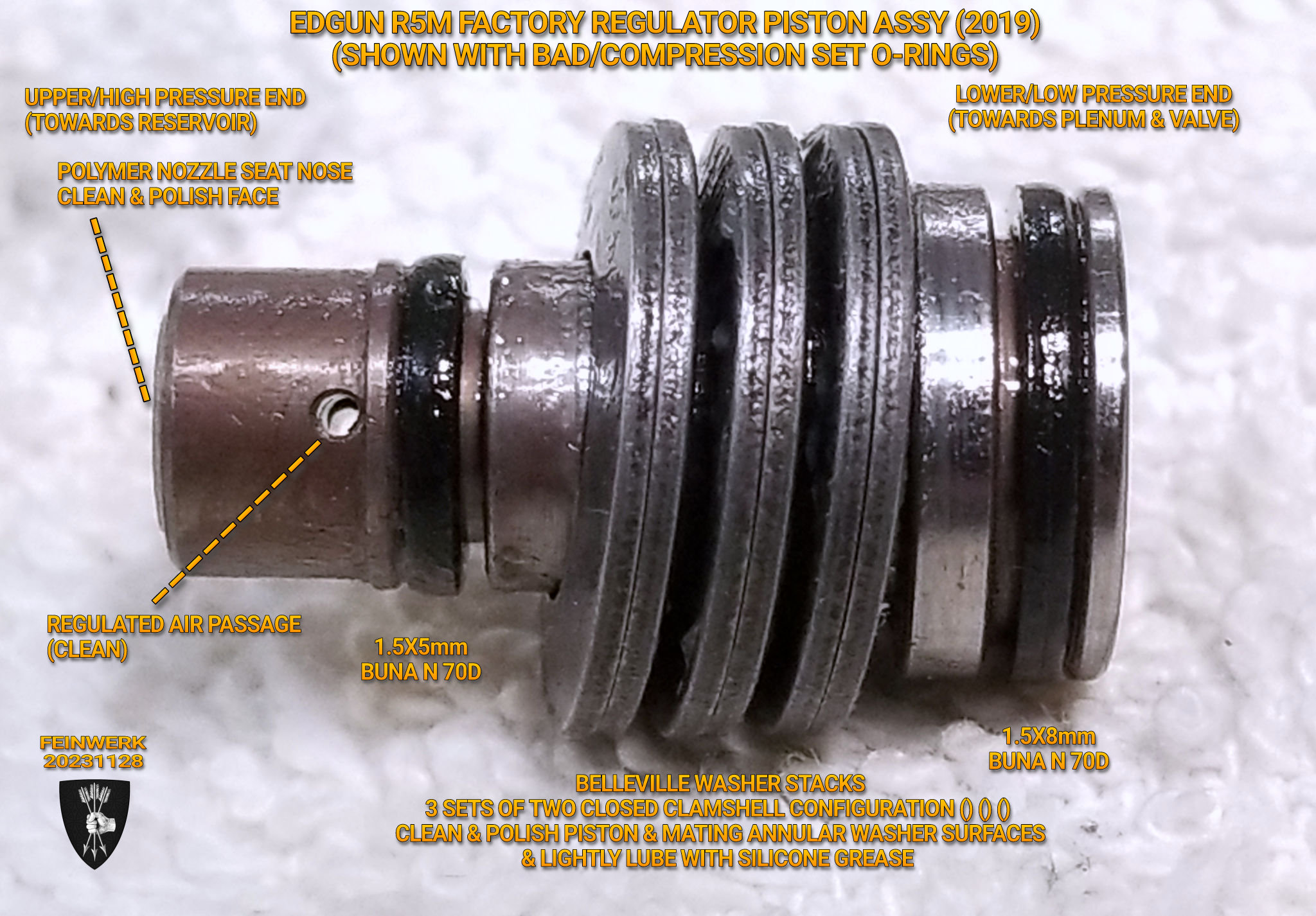

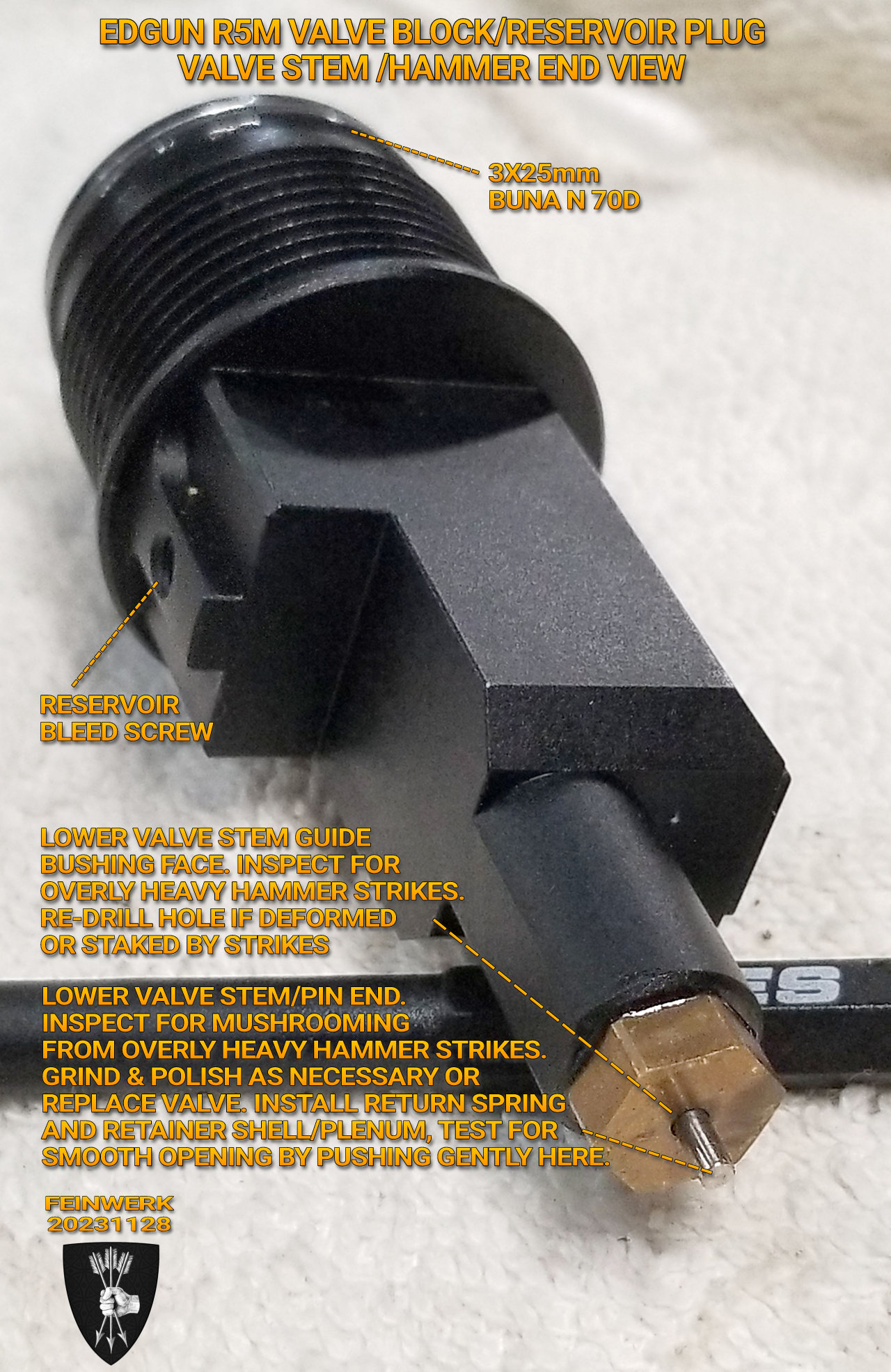

I recently serviced & re-sealed the regulator in my 2019 Edgun R5M and used the opportunity to take and annotate some photos of the parts. Annotations include O-ring sizes, notes for polishing and deburring, part orientation, and regulator screw adjustment. This should also apply to the Leyla, as I believe all these components are the same in both models.

I hope that some of you performing service on these guns will find some value here.

Regards,

Feinwerk

PS: here is a link to an older post that I placed in a different section of the forum, describing my troubles with a creeping regulator and broken valve that has a few more pictures. Further down in this older thread are also photos of the disassembly of the bolt block. I think I will repost them here in the resources section in a new thread.

www.airgunnation.com

www.airgunnation.com

I recently serviced & re-sealed the regulator in my 2019 Edgun R5M and used the opportunity to take and annotate some photos of the parts. Annotations include O-ring sizes, notes for polishing and deburring, part orientation, and regulator screw adjustment. This should also apply to the Leyla, as I believe all these components are the same in both models.

I hope that some of you performing service on these guns will find some value here.

Regards,

Feinwerk

PS: here is a link to an older post that I placed in a different section of the forum, describing my troubles with a creeping regulator and broken valve that has a few more pictures. Further down in this older thread are also photos of the disassembly of the bolt block. I think I will repost them here in the resources section in a new thread.

Edgun R5m Fill Pressure, Regulator Creep & Broken Valve Lessons

Hello all, I thought I'd take a moment to share a story of a surprise failure of my 3yr old Edgun R5m in .25 caliber. I originally tuned this gun to shoot JSB 25.4 gr at 875 fps (54 clicks CCW from full CW, for those of you who have worked on Edguns), where it has performed beautifully until the...

Last edited: