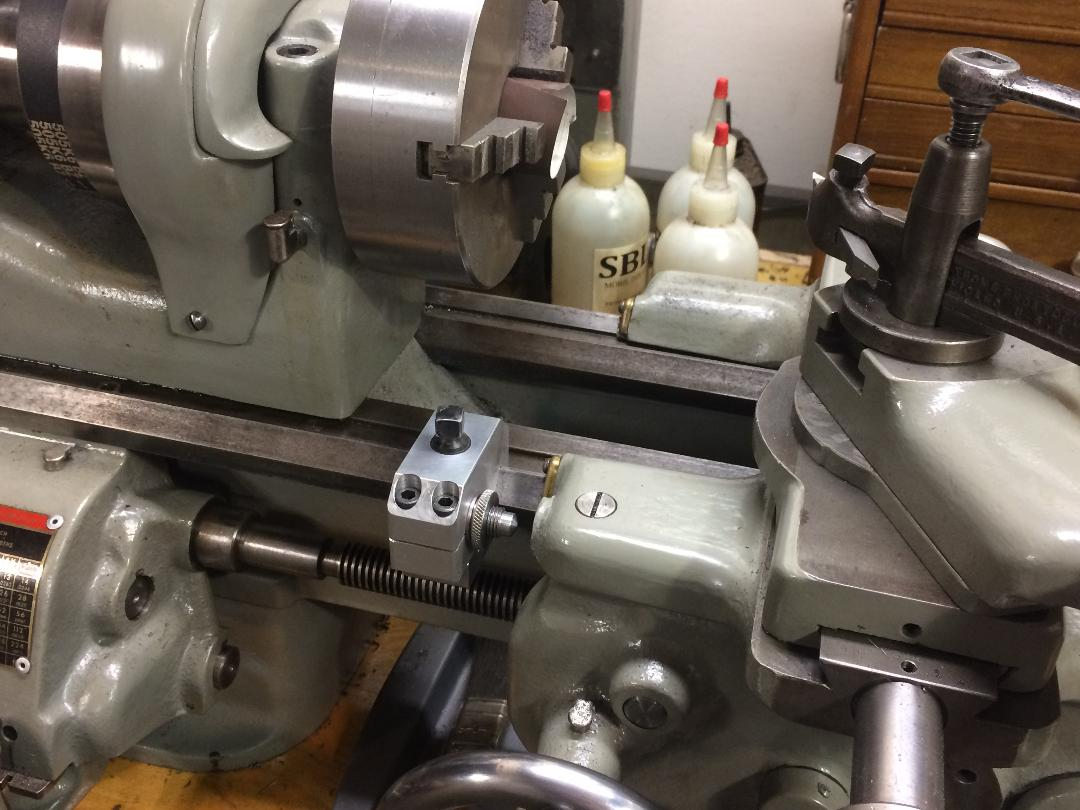

I made this carriage stop/Indicator holder so I have one for each of my two South Bend 9's. Just made it up in my head, you know. I can use either the thread insert or the slit sleeve to hold a dial indicator. I made a square head bolt so it uses the 3/8" toolpost wrench. Same as the carriage lock bolt as well. I made it the same profile as the other two bolt heads. Notice the last picture. The pink image on the surface (last picture) is a reflection. That's how nice the Logan metal shaper finishes aluminum. Better than a fly cutter on a milling machine. You should also be getting a finish like this on your lathe cutting aluminum with HSS. It's hard to get that to show up in pictures. I used the metal shaper for several of the operations because I can!

Kerosene is the best cutting fluid for aluminum. But it stinks so I use mineral spirits. Don't douse your part or whole machine with it. Just brush a little on. And it's flammable so don't burn the shop down!

A nice metal shaper finish on aluminum. See the reflection of the 1/4" socket and bolt? Cut with a HSS blank ground for use on a lathe. If you're not getting a finish like this with aluminum on the lathe you're doing something wrong.

Kerosene is the best cutting fluid for aluminum. But it stinks so I use mineral spirits. Don't douse your part or whole machine with it. Just brush a little on. And it's flammable so don't burn the shop down!

A nice metal shaper finish on aluminum. See the reflection of the 1/4" socket and bolt? Cut with a HSS blank ground for use on a lathe. If you're not getting a finish like this with aluminum on the lathe you're doing something wrong.