Bit of FUN today ... no shooting just tinkering around.

Guns too loud !! ... Cure, make some insert-able baffle / spacer assemblies removing that weird tube set up. It fits back together & one would never know .. and it is QUIETER !!

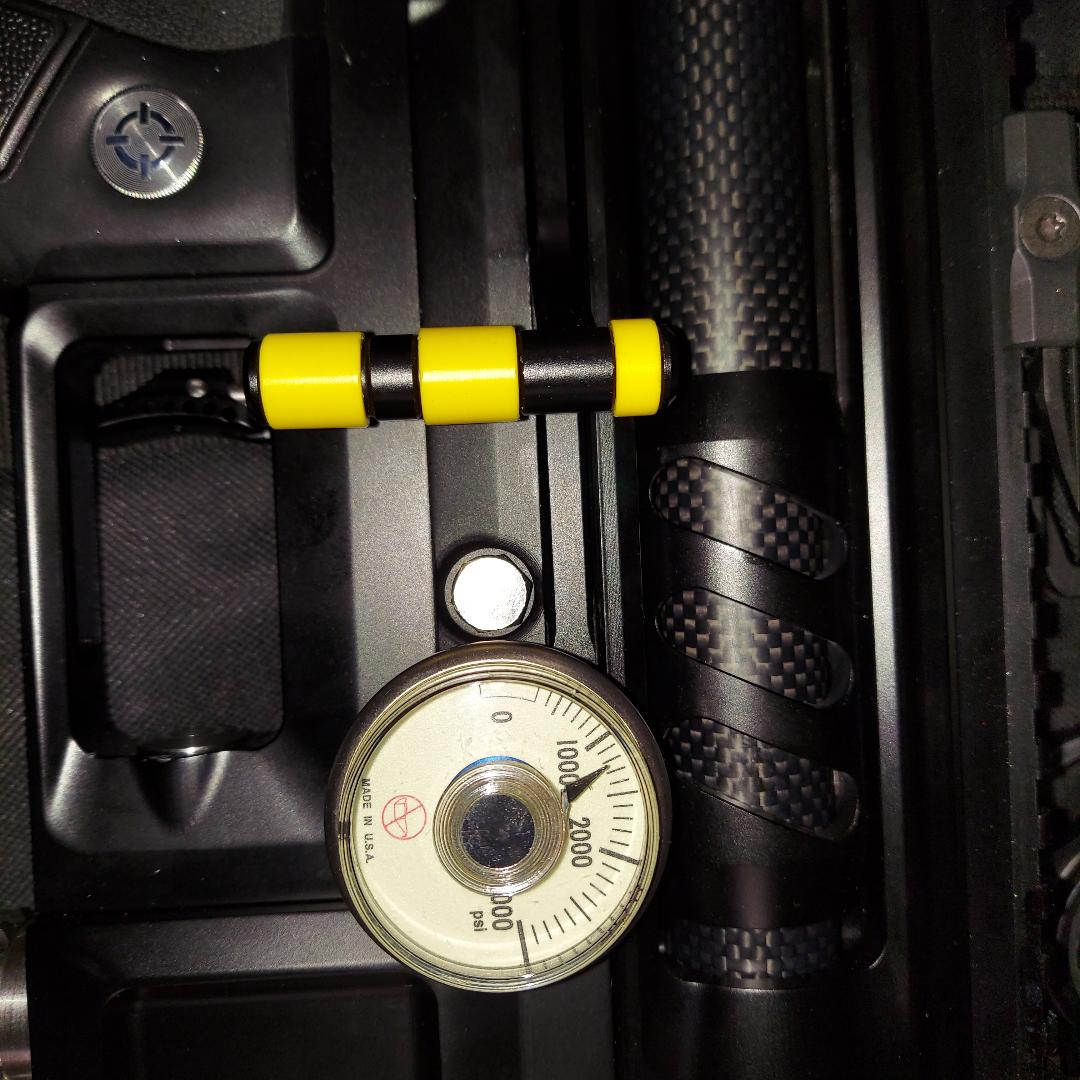

Made some delrin sleeves that get split with a razor blade & snapped onto cocking handle. They roll under your fingers and feel excellent when speed cocking. ( After & Before pictures )

Fit in 2 thin .003" shims on both sides of trigger pivot post to eliminate the side/side wiggle present.

Guns too loud !! ... Cure, make some insert-able baffle / spacer assemblies removing that weird tube set up. It fits back together & one would never know .. and it is QUIETER !!

Made some delrin sleeves that get split with a razor blade & snapped onto cocking handle. They roll under your fingers and feel excellent when speed cocking. ( After & Before pictures )

Fit in 2 thin .003" shims on both sides of trigger pivot post to eliminate the side/side wiggle present.

Attachments

Last edited:

Upvote 0