This thread was written after discussions on lead free slugs. It contains a lot of information and graphs. For those who do not like graphs and tables, it may be useful to just skip to the end following the final table where I have tried to summarise the results.

This is a first look at what may happen if slugs have to be made from an alternative to lead. The material I have used for the modelling is tin. The slugs are all .22 calibre based on a commercial design, with a hollow point nose just short of one calibre long, and a cylindrical aft portion of different lengths to give different slug masses. The design is a fairly standard one, with many of the currently available lead slugs being very similar in shape and size, and can be seen below.

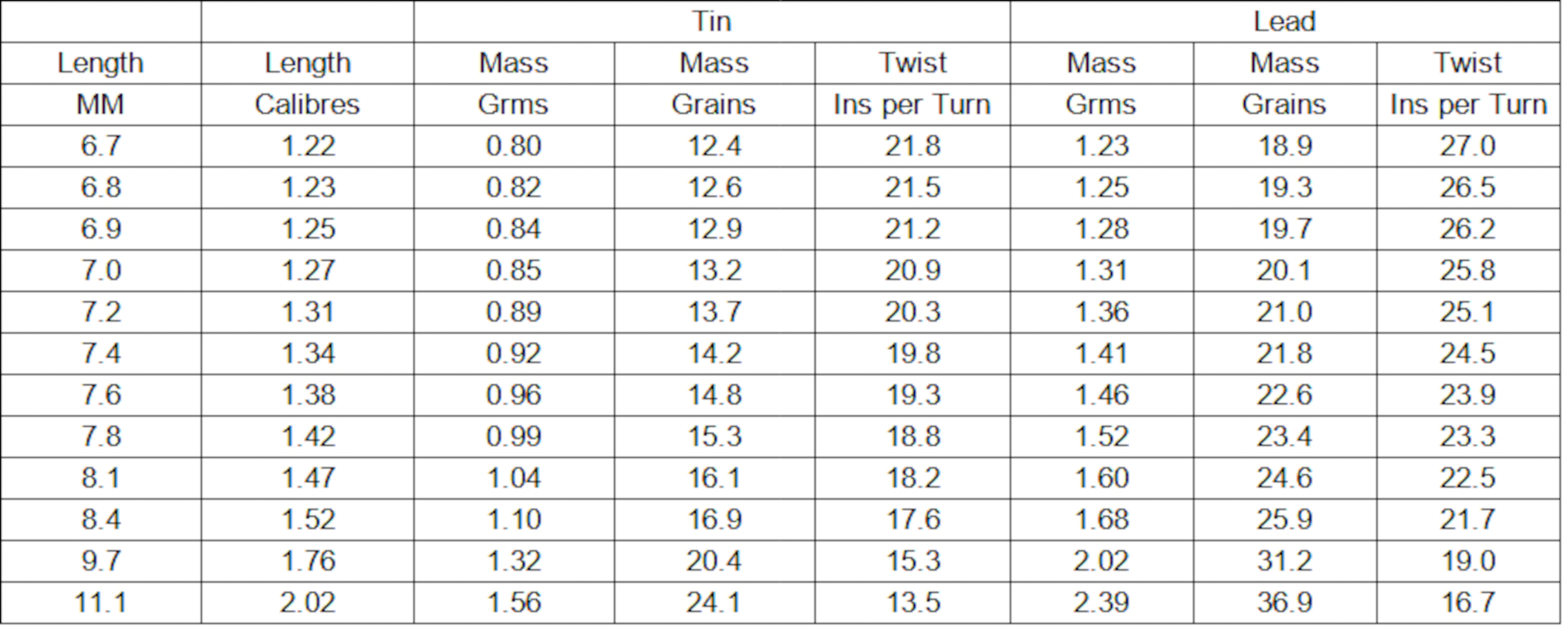

Slug overall lengths varied from 6.7mm to just over 11mm. Slug masses for the tin slugs varied from 12 to 24 grains, while the identical slugs made from lead varied from 19 to 37 grains. The muzzle velocity for all the slugs was fixed at 950ft/sec. The use of a fixed muzzle velocity is an initial starting point.

I could have used a fixed muzzle energy, but some of the tin slugs then end up travelling at supersonic velocities or some of the lead slugs would be travelling very slowly. To start the examination I wanted to introduce some fixed parameters to simplify the modelling which already required intensive production of many types of data files.

To produce an error at the target end of the trajectory, I first used an initial yawing rate of ten radians per second on each of the slugs. The maximum range in all cases was 75 yards.

The first job was to calculate the mass, centre of gravity and moments of inertia for each of the slugs. These characteristics are necessary for the rest of the input data files and for the stability calculations. The next job was to predict the aerodynamic properties of each slug using the calculated centre of gravity. For the aerodynamic properties, I used an aerodynamic prediction program created years ago for bullets and shells. There are some errors in the aerodynamic calculations for each of the slugs, but since this is a comparison between lead and lead free slugs, the errors should not invalidate the comparison.

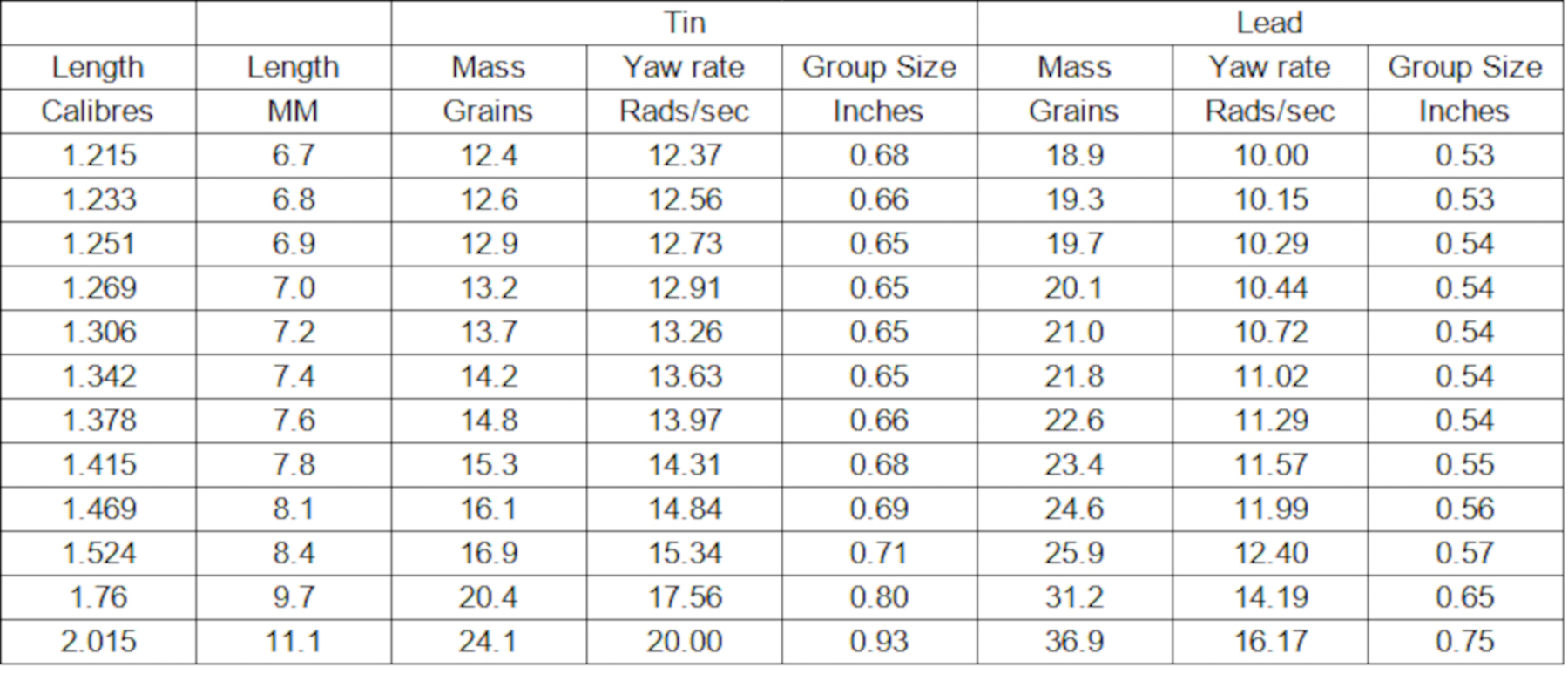

For rifle bullets, it is generally considered that a stability factor of 1.5 is the minimum required for good performance. For this reason, I calculated the barrel twist rate needed to have a stability factor of 1.5 for each slug, both lead and non-lead. The calculated twist rates needed for the required stability factor were then used in the trajectory modelling for each slug. The table below shows the slug lengths, mass and barrel twist rates for both the tin and lead slugs.

The table immediately shows up some problems for shooters and designers. For a given length of slug the tin one is much lighter, which is to be expected, and it requires a higher twist rate for the same stability factor. For the gun owner this means that unless he changes his barrel for one with a higher twist rate a shorter slug in tin will be required compared to a lead one, which will make the mass loss even greater. For example, a gun with a 22 inch twist rate will only be able to fire tin slugs of around 12 grains instead of the 25 grains for a long lead slug which could be used previously. The gun will also need adjustment to reduce the muzzle velocity if supersonic speeds are to be avoided.

There are also problems for slug manufacturers as well. Tin slugs will need increased barrel twist rates if the slug mass is to be preserved. Take a 24 grain slug mass as an example. A 24 grain lead slug will only need a 23 inch twist rate, whereas a 24 grain tin slug needs a 13 inch rate. Selling a slug which requires such a high twist rate to the general public as opposed to enthusiastic experienced shooters willing to change their barrel could prove challenging.

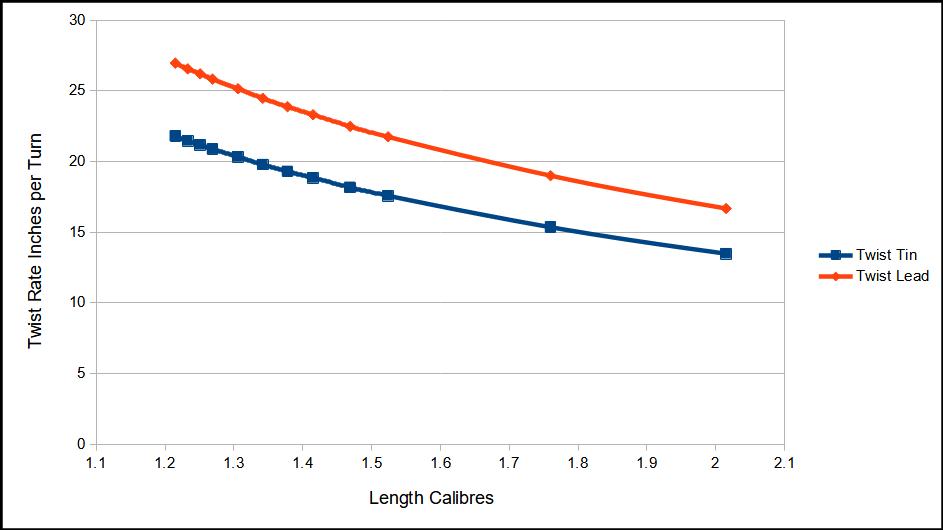

The graph below shows how the necessary twist rate varies with slug length for both the tin and lead slugs.

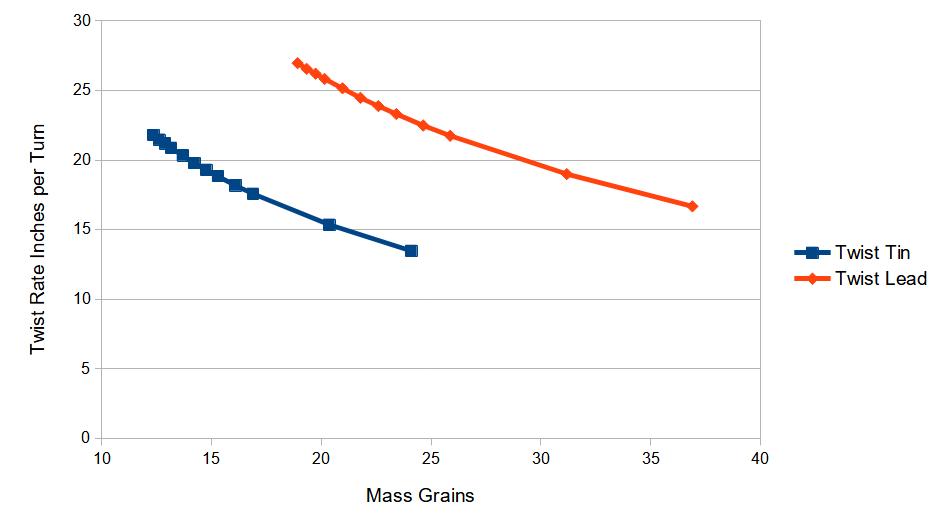

If the slug mass is of interest the comparison for tin and lead slugs is shown here.

Remember, these numbers are for this design of slug fired at 950ft/sec. Other slug designs or slugs fired at higher muzzle velocities may need faster twist rates.

For each slug, both lead and tin, two trajectories had to be run, one with no yaw rate on the slug and one with the 10 radians per second yaw rate at the start of the trajectory. There was a slight problem in that the modelling suggested that the shorter slugs suffered from a dynamic instability leading to increasing yaw and a slight spiralling effect at the end of some trajectories. To overcome this, a straight line was fitted to the error calculations (initial yaw rate errors give a linear increase in error with range). The slugs are probably not going to be dynamically unstable in real life, it is just very difficult to predict it accurately, particularly for small projectiles.

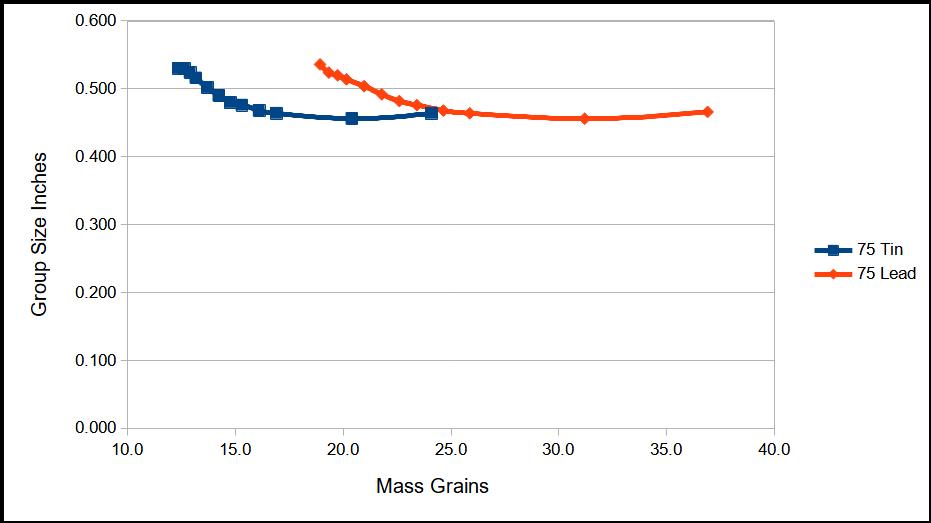

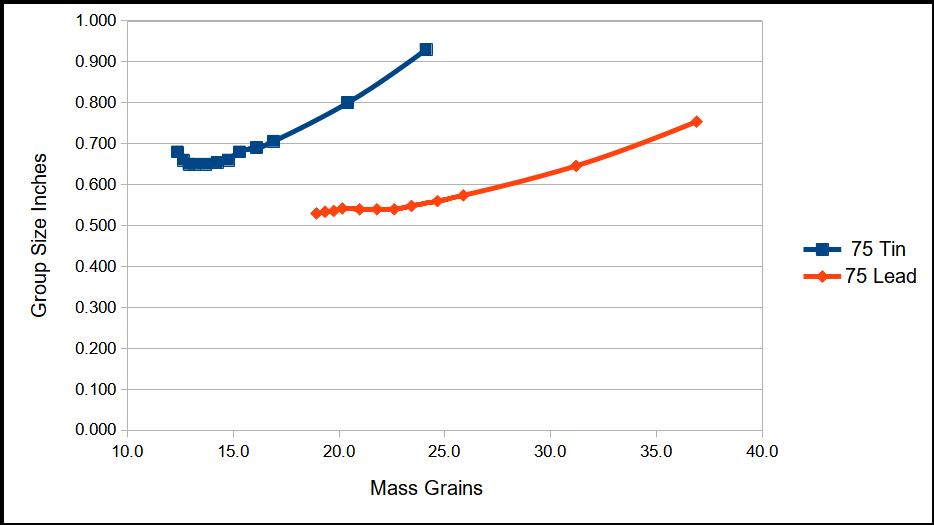

The predicted group sizes at 75 yards range for both the tin and lead slugs as a function of slug mass is shown here.

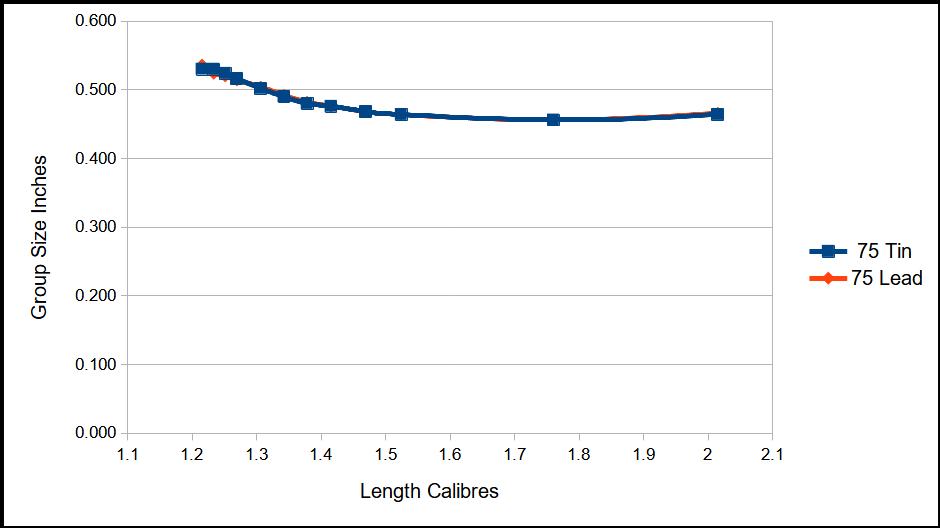

The group sizes look very similar. Looking at the group size as a function of slug length gives an easier comparison.

There are actually two curves there, but the lead one lies directly underneath the tin curve, something we would not expect. It would appear that with the same initial error, stability factor and muzzle velocity, slugs of the same length will give the same group size.

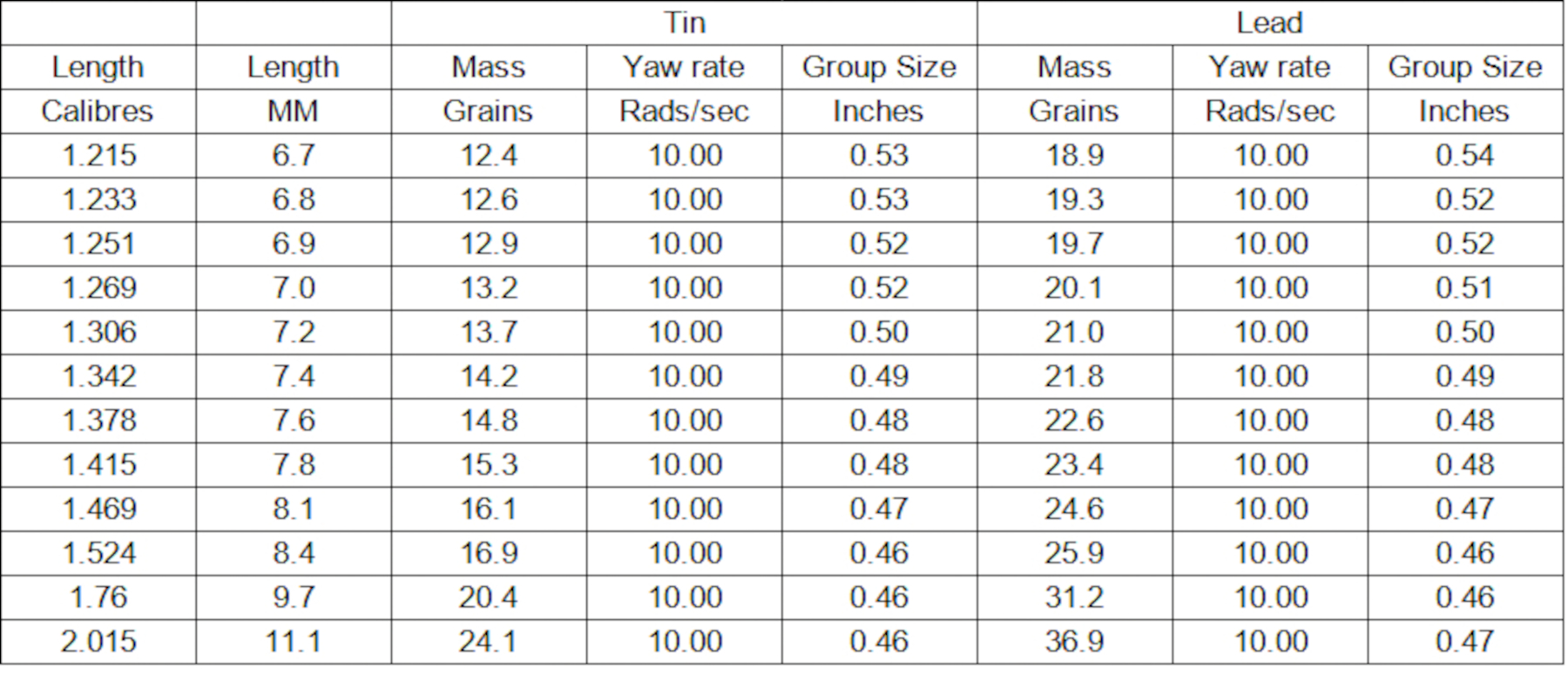

The group size results in tabular form for a fixed initial yaw rate are shown below.

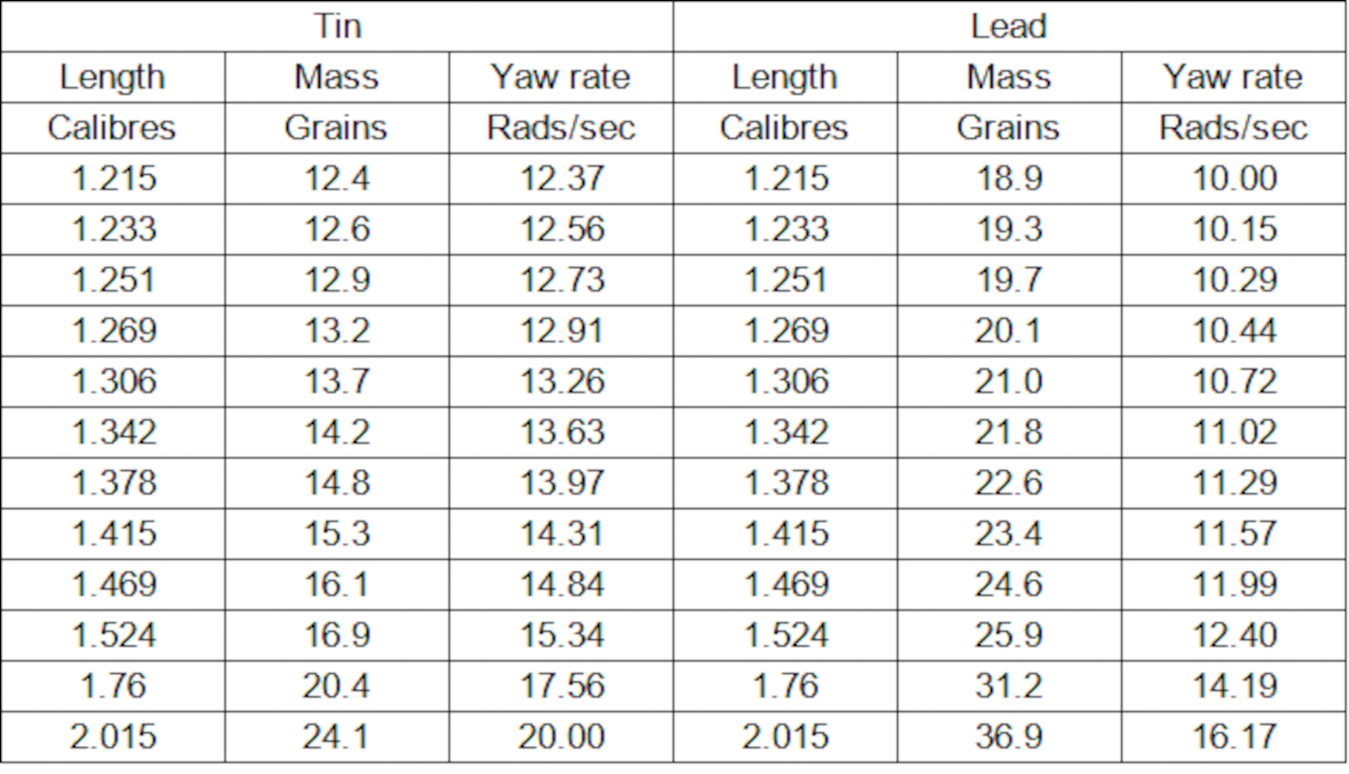

This exercise is supposed to be concentrating on projectile error sources and looking at how the slug reacts. With the different twist rates for tin slugs, it seems unlikely that projectile based error sources would give the same initial yawing rate as the slug leaves the barrel. To take account of this, the 10 radians per second yaw rate was kept for the slug requiring the slowest twist rate and all the other slugs yaw rates were adjusted in proportion to their barrel twist rates. The resulting initial yaw rates for each slug are shown below.

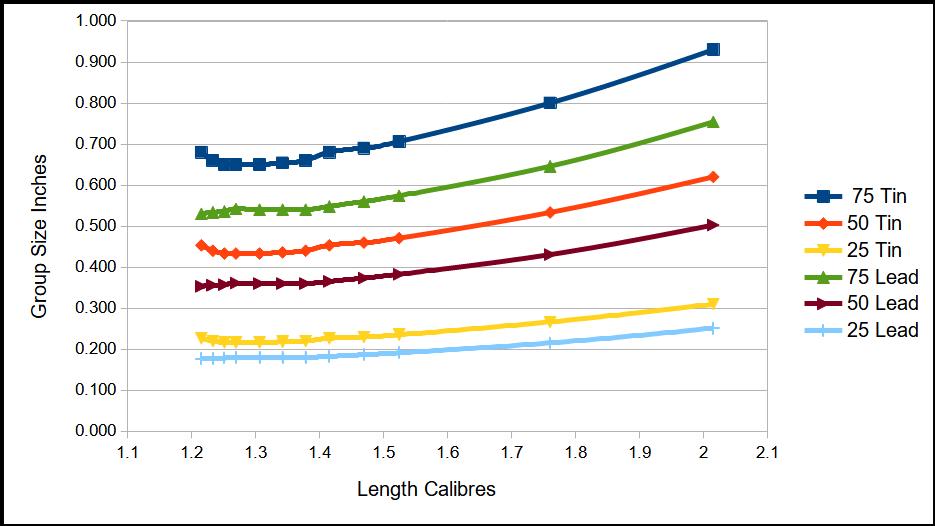

The group size results are now very different for tin and lead slugs. Below you can see the group sizes at 25, 50 and 75 yards for the lead and tin slugs.

In this case, for a given slug length, the lead slug always gives smaller groups than the equivalent tin slug, about 20% less. This is more in agreement with the results of a pellet study comparing pellets made of zinc and lead. The group sizes as a function of slug mass at 75 yards are shown here.

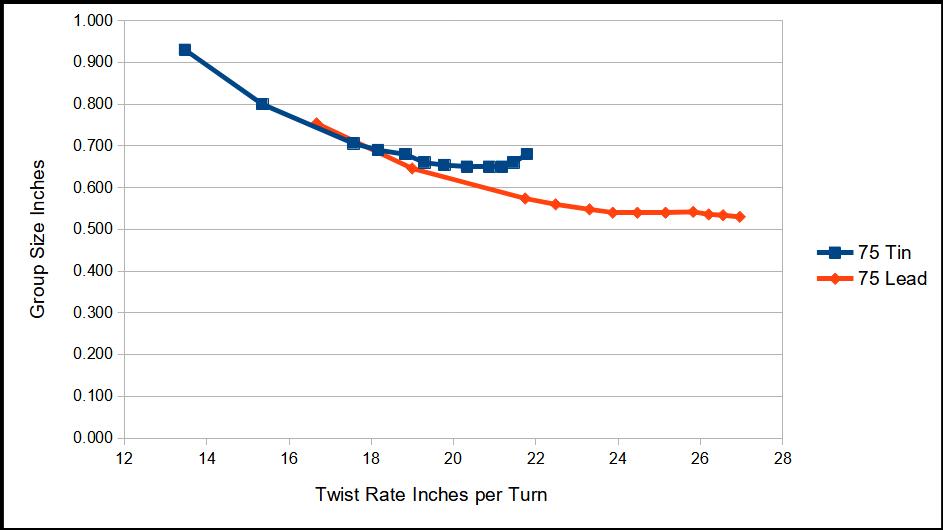

According to this chart, a lead slug of much greater mass can be fired for the same group sizes as the shorter, much lighter tin slug. Finally, for shooters with a fixed twist rate, the diagram below shows how the group size for tin and lead slugs varies with twist rate for the fixed stability factor.

Below are the group size results for twist rate related yaw rates at 75 yards in tabular form.

So what does it all mean? For shooters, unless you change the barrel on your gun to have a much faster twist rate, you will only be able to use much lighter and shorter slugs in tin than you could in lead. To avoid the new tin slugs travelling at supersonic speeds, you will also have to reduce the muzzle energy of your gun. Tin slugs of the same mass as some lead slugs can be used, but they may be too long to fit in the magazine and will need an even higher twist rate.

For slug makers, the problem will be how do you make a tin based slug which can use pellet type twist rates without going ultra short and light. Making a tin slug the same mass as a lead slug can be done, but it will be much longer and may well not work with standard twist rate barrels or fit in magazines.

There are still lots of variables which can be changed such as different stability factors, different error sources in the slugs, different muzzle velocities or constant muzzle energies. Each one could change the resulting group sizes, but tin slugs will always need much higher twist rates in the barrel than the equivalent length or weight lead slug.

This is a first look at what may happen if slugs have to be made from an alternative to lead. The material I have used for the modelling is tin. The slugs are all .22 calibre based on a commercial design, with a hollow point nose just short of one calibre long, and a cylindrical aft portion of different lengths to give different slug masses. The design is a fairly standard one, with many of the currently available lead slugs being very similar in shape and size, and can be seen below.

Slug overall lengths varied from 6.7mm to just over 11mm. Slug masses for the tin slugs varied from 12 to 24 grains, while the identical slugs made from lead varied from 19 to 37 grains. The muzzle velocity for all the slugs was fixed at 950ft/sec. The use of a fixed muzzle velocity is an initial starting point.

I could have used a fixed muzzle energy, but some of the tin slugs then end up travelling at supersonic velocities or some of the lead slugs would be travelling very slowly. To start the examination I wanted to introduce some fixed parameters to simplify the modelling which already required intensive production of many types of data files.

To produce an error at the target end of the trajectory, I first used an initial yawing rate of ten radians per second on each of the slugs. The maximum range in all cases was 75 yards.

The first job was to calculate the mass, centre of gravity and moments of inertia for each of the slugs. These characteristics are necessary for the rest of the input data files and for the stability calculations. The next job was to predict the aerodynamic properties of each slug using the calculated centre of gravity. For the aerodynamic properties, I used an aerodynamic prediction program created years ago for bullets and shells. There are some errors in the aerodynamic calculations for each of the slugs, but since this is a comparison between lead and lead free slugs, the errors should not invalidate the comparison.

For rifle bullets, it is generally considered that a stability factor of 1.5 is the minimum required for good performance. For this reason, I calculated the barrel twist rate needed to have a stability factor of 1.5 for each slug, both lead and non-lead. The calculated twist rates needed for the required stability factor were then used in the trajectory modelling for each slug. The table below shows the slug lengths, mass and barrel twist rates for both the tin and lead slugs.

The table immediately shows up some problems for shooters and designers. For a given length of slug the tin one is much lighter, which is to be expected, and it requires a higher twist rate for the same stability factor. For the gun owner this means that unless he changes his barrel for one with a higher twist rate a shorter slug in tin will be required compared to a lead one, which will make the mass loss even greater. For example, a gun with a 22 inch twist rate will only be able to fire tin slugs of around 12 grains instead of the 25 grains for a long lead slug which could be used previously. The gun will also need adjustment to reduce the muzzle velocity if supersonic speeds are to be avoided.

There are also problems for slug manufacturers as well. Tin slugs will need increased barrel twist rates if the slug mass is to be preserved. Take a 24 grain slug mass as an example. A 24 grain lead slug will only need a 23 inch twist rate, whereas a 24 grain tin slug needs a 13 inch rate. Selling a slug which requires such a high twist rate to the general public as opposed to enthusiastic experienced shooters willing to change their barrel could prove challenging.

The graph below shows how the necessary twist rate varies with slug length for both the tin and lead slugs.

If the slug mass is of interest the comparison for tin and lead slugs is shown here.

Remember, these numbers are for this design of slug fired at 950ft/sec. Other slug designs or slugs fired at higher muzzle velocities may need faster twist rates.

For each slug, both lead and tin, two trajectories had to be run, one with no yaw rate on the slug and one with the 10 radians per second yaw rate at the start of the trajectory. There was a slight problem in that the modelling suggested that the shorter slugs suffered from a dynamic instability leading to increasing yaw and a slight spiralling effect at the end of some trajectories. To overcome this, a straight line was fitted to the error calculations (initial yaw rate errors give a linear increase in error with range). The slugs are probably not going to be dynamically unstable in real life, it is just very difficult to predict it accurately, particularly for small projectiles.

The predicted group sizes at 75 yards range for both the tin and lead slugs as a function of slug mass is shown here.

The group sizes look very similar. Looking at the group size as a function of slug length gives an easier comparison.

There are actually two curves there, but the lead one lies directly underneath the tin curve, something we would not expect. It would appear that with the same initial error, stability factor and muzzle velocity, slugs of the same length will give the same group size.

The group size results in tabular form for a fixed initial yaw rate are shown below.

This exercise is supposed to be concentrating on projectile error sources and looking at how the slug reacts. With the different twist rates for tin slugs, it seems unlikely that projectile based error sources would give the same initial yawing rate as the slug leaves the barrel. To take account of this, the 10 radians per second yaw rate was kept for the slug requiring the slowest twist rate and all the other slugs yaw rates were adjusted in proportion to their barrel twist rates. The resulting initial yaw rates for each slug are shown below.

The group size results are now very different for tin and lead slugs. Below you can see the group sizes at 25, 50 and 75 yards for the lead and tin slugs.

In this case, for a given slug length, the lead slug always gives smaller groups than the equivalent tin slug, about 20% less. This is more in agreement with the results of a pellet study comparing pellets made of zinc and lead. The group sizes as a function of slug mass at 75 yards are shown here.

According to this chart, a lead slug of much greater mass can be fired for the same group sizes as the shorter, much lighter tin slug. Finally, for shooters with a fixed twist rate, the diagram below shows how the group size for tin and lead slugs varies with twist rate for the fixed stability factor.

Below are the group size results for twist rate related yaw rates at 75 yards in tabular form.

So what does it all mean? For shooters, unless you change the barrel on your gun to have a much faster twist rate, you will only be able to use much lighter and shorter slugs in tin than you could in lead. To avoid the new tin slugs travelling at supersonic speeds, you will also have to reduce the muzzle energy of your gun. Tin slugs of the same mass as some lead slugs can be used, but they may be too long to fit in the magazine and will need an even higher twist rate.

For slug makers, the problem will be how do you make a tin based slug which can use pellet type twist rates without going ultra short and light. Making a tin slug the same mass as a lead slug can be done, but it will be much longer and may well not work with standard twist rate barrels or fit in magazines.

There are still lots of variables which can be changed such as different stability factors, different error sources in the slugs, different muzzle velocities or constant muzzle energies. Each one could change the resulting group sizes, but tin slugs will always need much higher twist rates in the barrel than the equivalent length or weight lead slug.

Last edited: