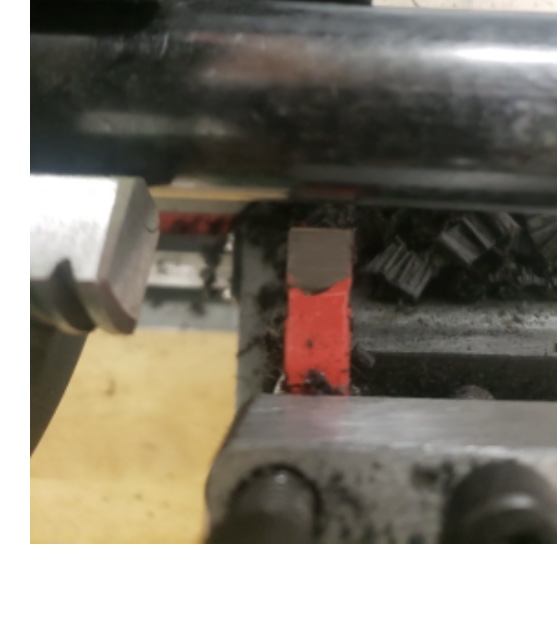

Im trying to teach myself to make my own guides but seem to have run into some issues. My cuts seem to start out well but as I get closer to the chuck I start to get "ribs" in the material. I'm a complete beginner so any advice is appreciated. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with lathe

- Thread starter Sqwirl57

- Start date

Sub12 Airgunners uses positive rake inserts for everything I've seen in his videos. Really nice setup he's got.That insert appears to be a POS/NEG. Definitely a problem solver insert. A drop in insert for a regular negative rake tool holder.

Upvote 0

Hang in there, you’ll get this!

As others have mentioned, hss and sharp. Round nose.

Something else I noticed in this picture

Your tool presents quite a bit of cutting edge to the part. If you’re like I was when I started, I didn’t have a bunch of bits and had to make do. Try setting that tool at a 45 angle to the workpiece, it will present a smaller ‘nose’ to the workpiece, you want just the corner of it touching.

A lot of good advice you got here so far. You’ll get it figured out.

Dave

As others have mentioned, hss and sharp. Round nose.

Something else I noticed in this picture

Your tool presents quite a bit of cutting edge to the part. If you’re like I was when I started, I didn’t have a bunch of bits and had to make do. Try setting that tool at a 45 angle to the workpiece, it will present a smaller ‘nose’ to the workpiece, you want just the corner of it touching.

A lot of good advice you got here so far. You’ll get it figured out.

Dave

Upvote 0

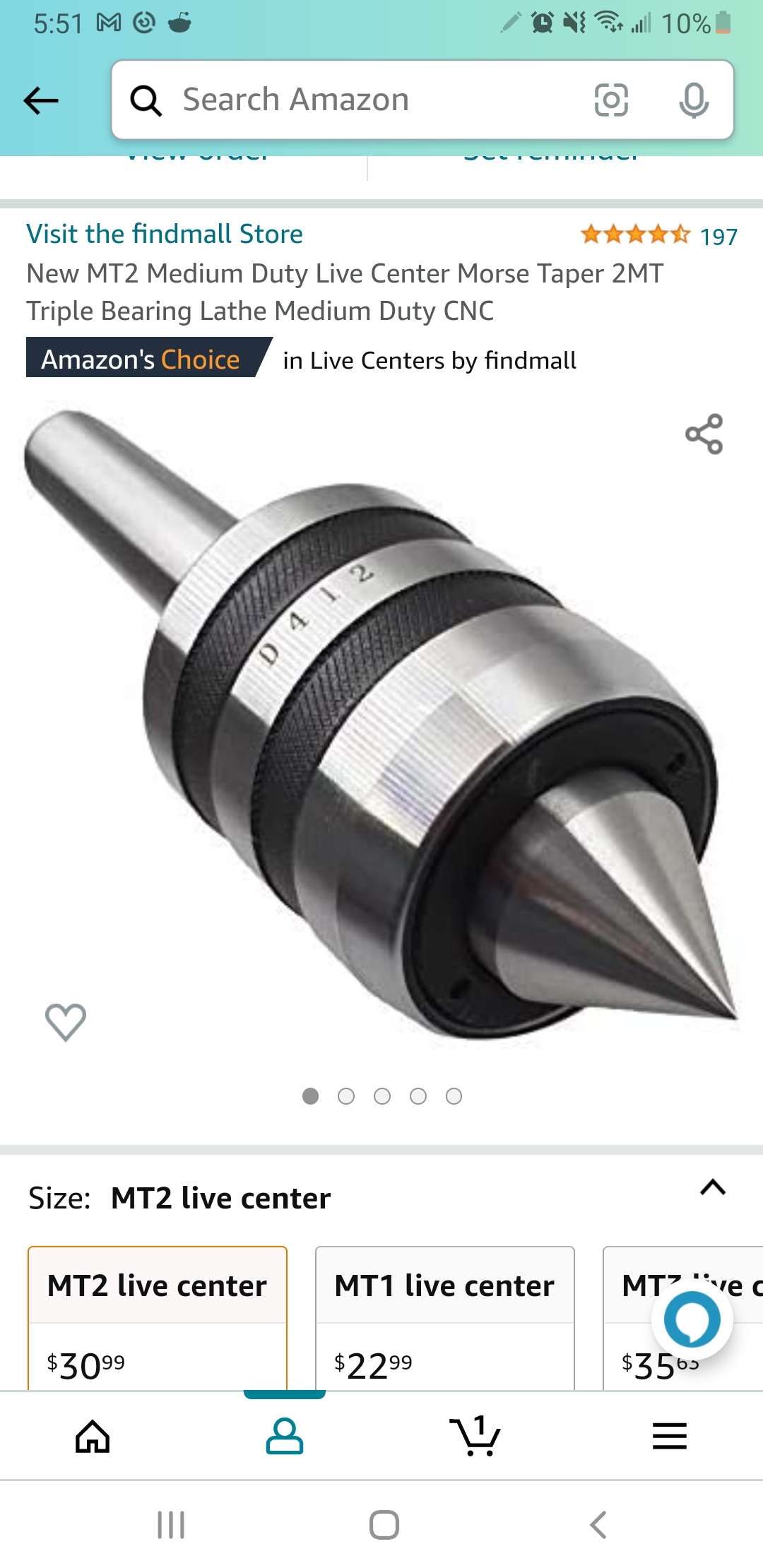

I'll be ordering some new tools, a quick change tool post, and a live center tomorrow. Excited to really get into this. My first guide is done (not great but its done!) and I'm looking forward to trying again and doing a bit better

Upvote 0

hmm .. i would guess its a screw out of round (bent) combined with some clearance play in something, maybe a few things .. in other words a scenario which may or may not be the case but as an example - if there was a warp 'bind' or trash in the lead screw and you were using it to power, it could lift and move the entire carriage on each revolution ... i rebuilt and scrutinized every part of my chinese mini lathe and found many small issues to iron out, that combined could lead to larger problems for sure ... spent almost a month of spare time on the rebuild .. an out of the box precision machine a cheap lathe is not, but they can be with alot of attention ..

Last edited:

Upvote 0

Be sure to get tooling that fits your machine. If you need help just post the machine info for suggestions.I'll be ordering some new tools, a quick change tool post, and a live center tomorrow. Excited to really get into this. My first guide is done (not great but its done!) and I'm looking forward to trying again and doing a bit better

Upvote 0

Its nothing fancy. Just some Chinese ebay special. A Preenex 8x16 I believe? Here's a link to itBe sure to get tooling that fits your machine. If you need help just post the machine info for suggestions.

Upvote 0

Throw that brazed on carbide bit in the trash. That's your problem. It might be useful for making butter sculpture. Total useless junk.

Upvote 0

Throw that brazed on carbide bit in the trash. That's your problem. It might be useful for making butter sculpture. Total useless junk.

Its getting better lol but yeah I wasn't expecting this $14 Harbor Freight set to be great and as it turns out, it isn't. If someone would like to share a link of some decent tooling I would appreciate it. There are too many options and I dont want to buy something else that doesn't work well

Upvote 0

Has to be increased vibration as you approach the Headstock. Make sure the live center in the Tailstock is locked down and applying enough pressure to the stock as it's chucked. Is there looseness/shakiness in the headstock as you apply pressure?Im trying to teach myself to make my own guides but seem to have run into some issues. My cuts seem to start out well but as I get closer to the chuck I start to get "ribs" in the material. I'm a complete beginner so any advice is appreciated. Thank you!View attachment 291346

Also, you may need to tune/tighten the screws to the gibbs on the tool post or where the Carriage meets the lathe bed.

When I bought my Harbor Freight 7" x 14" Lathe, I spent a week just tuning/adjusting/fixing it ...

Upvote 0

Will you be using an AXA size quick change tool post?If someone would like to share a link of some decent tooling I would appreciate it. There are too many options and I dont want to buy something else that doesn't work well

Upvote 0

I'm going to agree that a quality insert for aluminum should help out significantly.

The lathe is the cheap part; you'll spend double or more in tooling.

I use an insert with a significant radius on it for general cutting; I'll change out the tool if I need a sharp shoulder.

The lathe is the cheap part; you'll spend double or more in tooling.

I use an insert with a significant radius on it for general cutting; I'll change out the tool if I need a sharp shoulder.

Upvote 0

You would be surprised how fast you will learn how to use your Lathe.

The Key is to listen and watch how the finish is on the part you are turning...

Chattering and squealing..means your tools is vibrating.... Poor Finish!!

Adjust your speed and feed .

I learned on a small table-top lathe..Taig.

Solid little guy I played with in college...

Also check your tool height...

Stuart

The Key is to listen and watch how the finish is on the part you are turning...

Chattering and squealing..means your tools is vibrating.... Poor Finish!!

Adjust your speed and feed .

I learned on a small table-top lathe..Taig.

Solid little guy I played with in college...

Also check your tool height...

Stuart

Upvote 0

You don't necessarily need a radius for a fine finish. Do I? It's all in your tool bit and the way it's presented to the part. These are mild steel parts. None polished. I take pride in the finish I get with hand ground tool bits. Dad often said there's only one way to learn to play the piano. Practice.

Upvote 0

I use a South Bend for several things at work and I strongly dislike the tool post. The thing is older than me and it’s smooth as butter. To the OP, check your gibbs right where your work is getting funky. I have a China lathe at home for smaller stuff and I spent some serious time lapping the bed.

Upvote 0

Ok so I bought a few goodies. Not sure if they're great but the reviews were solid. Also, I managed to turn myself a guide for my FWB Sport. What a difference that made. Well worth the investment now!

Upvote 0

I'd use a radius tool instead of sharp with more shear angle. It'd make for a smoother cut.It is hard to tell from your photos but your tool looks like it is sticking out a bit too far from the post. Also have you tried to feed from the Chuck toward the Center? If you have a Carbide tool try using it.

ThomasT

Upvote 0

Oops forgot to add that picture. I have one of these coming too because people had mentioned rounded tools meant for aluminum work wellI'd use a radius tool instead of sharp with more shear angle. It'd make for a smoother cut.

Upvote 0

That's a bit overkill, The inserts have a nice enough corner radius on them, trying to dredge up my memory on them, been a few decades. I want to say about .016 to .032Oops forgot to add that picture. I have one of these coming too because people had mentioned rounded tools meant for aluminum work wellView attachment 291915

Upvote 0