You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G

Guest

Guest

Well, dang. Lugged some 100lbs of stuff to the range, no lanes open. 2-gun case, Caldwell chrono with tripod, etc in it's own bag, & Osage River large shooter's bag full of gear. Going to try again Monday Morning about lunch time. didn't think this city full of PC yuppies would have so many hunter/shooters taking up every lane? Gotta find out when they're least busy. Lady at Gun Hub said to call around lunch time tomorrow to see if a lane(s) open up. Maybe I can get her to hold one till I get there> I explained about doing a report for 3/4/17 for ODNR & needing numbers, etc for that meeting.

Upvote 0

G

Guest

Guest

Well, the plot thickens. Darn it. I set up my back stop & new Caldwell deluxe chronograph with IR LED's. Then proceeded to put the two Co2 cartridges in the 160 & screw down the cap to pierce outer cartridge, then cock the bolt to pierce inner one. Pulled trigger, cocked the bolt, pulled the trigger again & all the gas leaked out on it's own something isn't sealing between shots somewhere? It fired while it still had gas, but wouldn't hold it between shots. Sounded like it was leaking out the barrel, then out the exhaust port to breech as well??? I did weigh the rifles in a new Youtube video. It now weighs 6lbs, 4.4ozs, minus Co2.

Upvote 0

G

Guest

Guest

ACHTUNG windmill01! Your wish will soon be granted! New gas valve assembly from Archer should be here today pony express. Hope it comes early enough to do a video of repair & chrono test? And Happy Fat Tuesday everybody!!!

Upvote 0

Check my January 29th post...(excerpt underlined and pasted below);"unionrdr".....all the gas leaked out on it's own something isn't sealing between shots somewhere? .....

"...your brass valve stem has a seal material that looks a LOT like what MAC-1 uses. It is great stuff, but needs to be warmed up to properly mate with its new valve. This only has to be done once. "

That seal material is stubborn, but darn near eternal when heated to conform to valve seat.

Asked you in that post if you wanted me to heat it to mate to that valve. Wasn't sure which one you wanted to use. Thought it best not to proceed without your approval in case you decided to return the brass one for refund .

Long story short from what I saw, that valve while pristine... may be your culprit until you heat that seal material (one time only) to mate to the valve seat.

Upvote 0

Unionrdr it's hump Wensday here, good old pony express. Still looking forward to your video.

Upvote 0

G

Guest

Guest

So, the chronograph numbers turned out like this. I'm sure that after I fix this sealing glitch they'll improve. Even look more stable shot to shot. So, this is what it looks like first time out;

H&N Baracuda Green 12.65gr

1) 650

2) 641

3) 629

4) 618

5) 599

6) 575

Average of six shots-

618.67FPS

Still not bad, with new Archer valve improving some 100FPS over factory valve.

H&N Baracuda Green 12.65gr

1) 650

2) 641

3) 629

4) 618

5) 599

6) 575

Average of six shots-

618.67FPS

Still not bad, with new Archer valve improving some 100FPS over factory valve.

Upvote 0

G

Guest

Guest

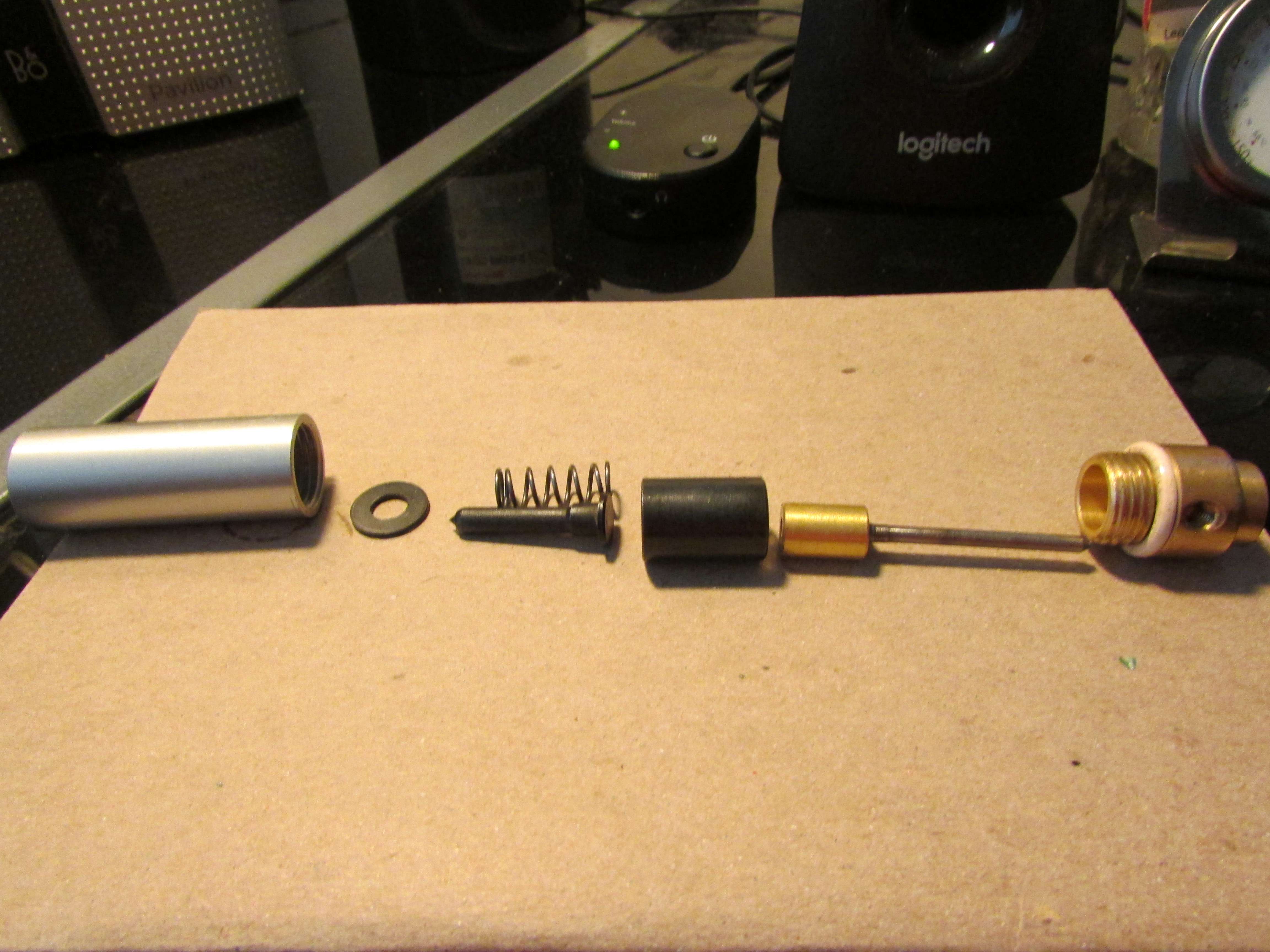

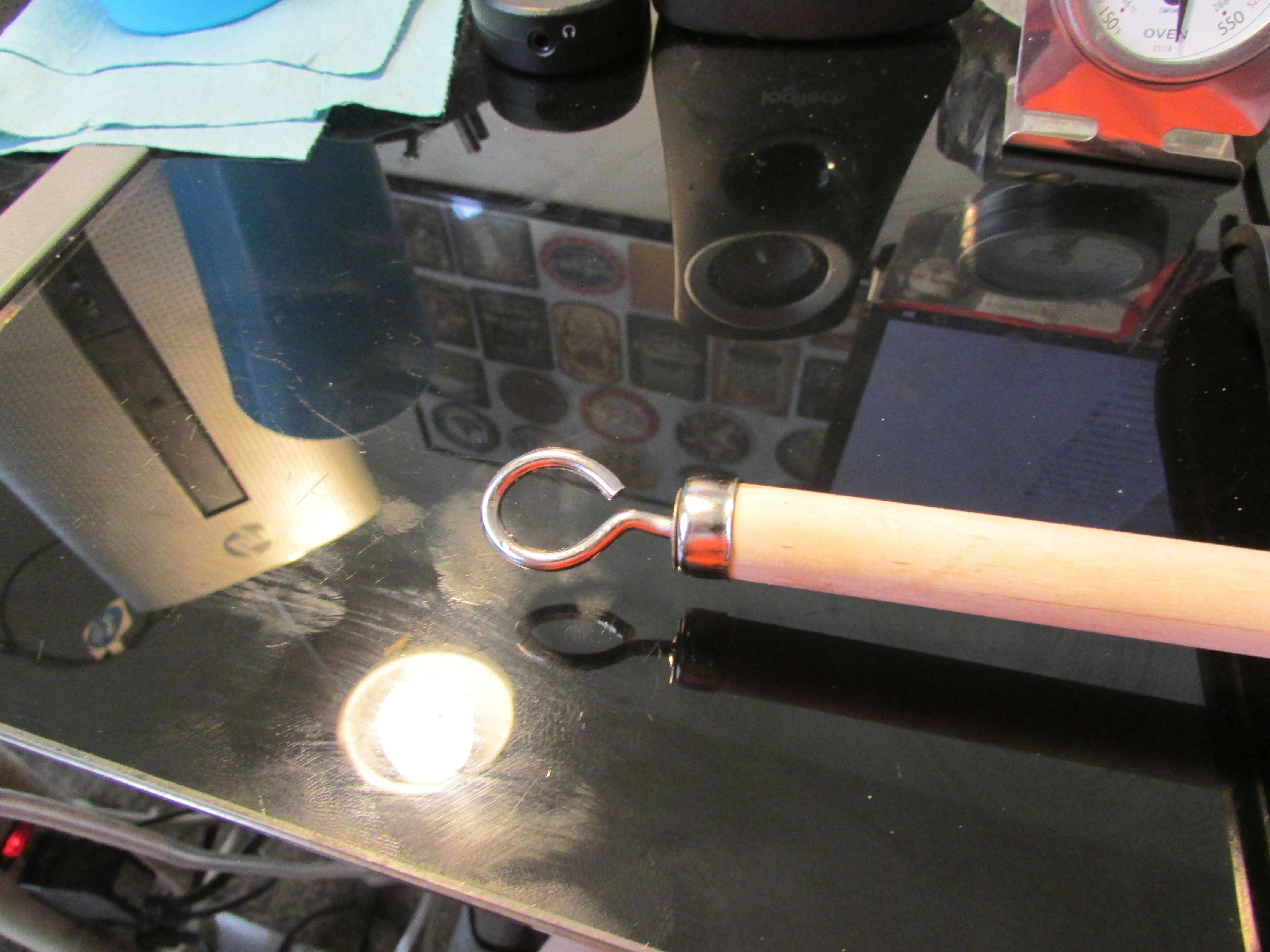

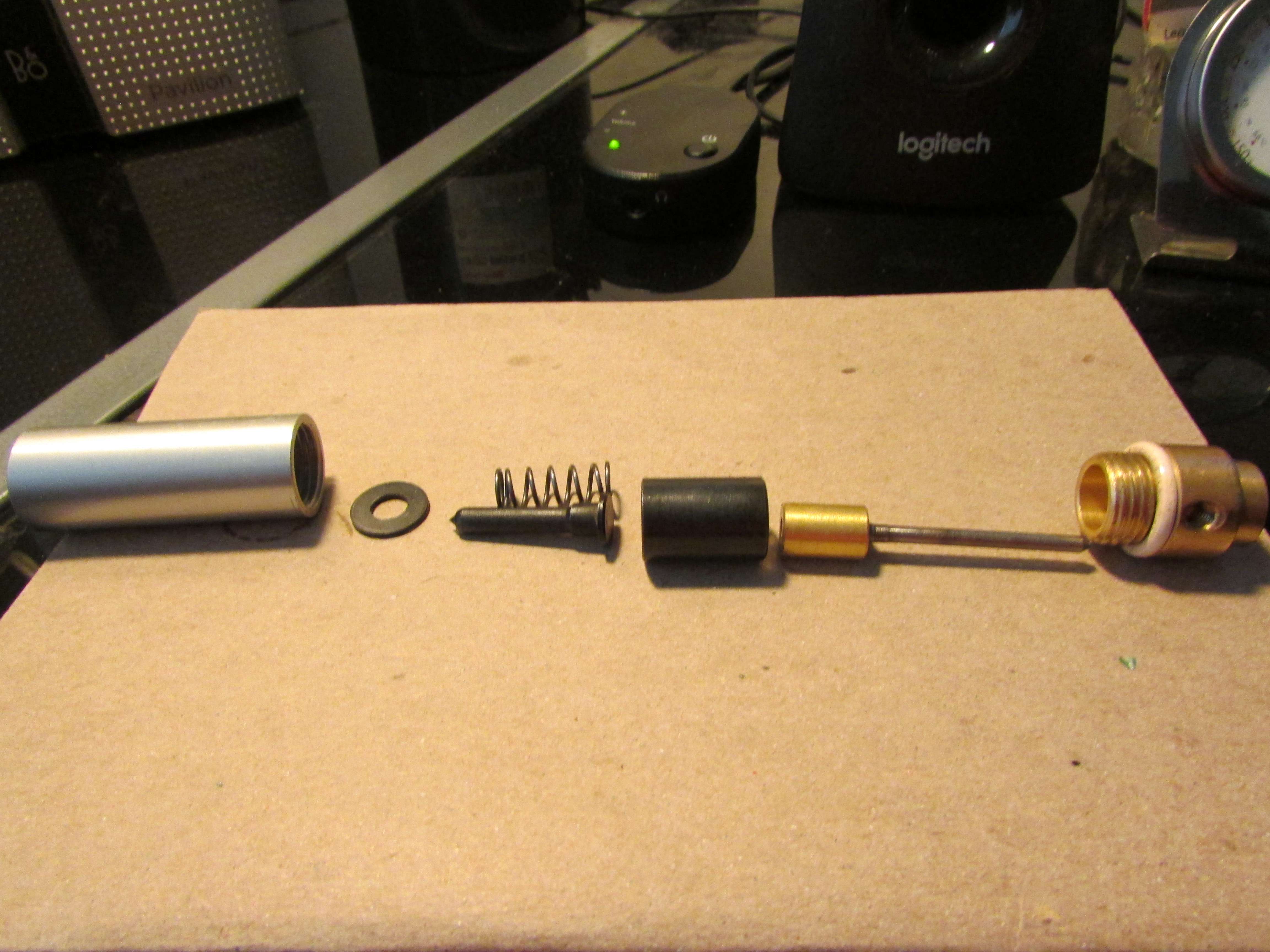

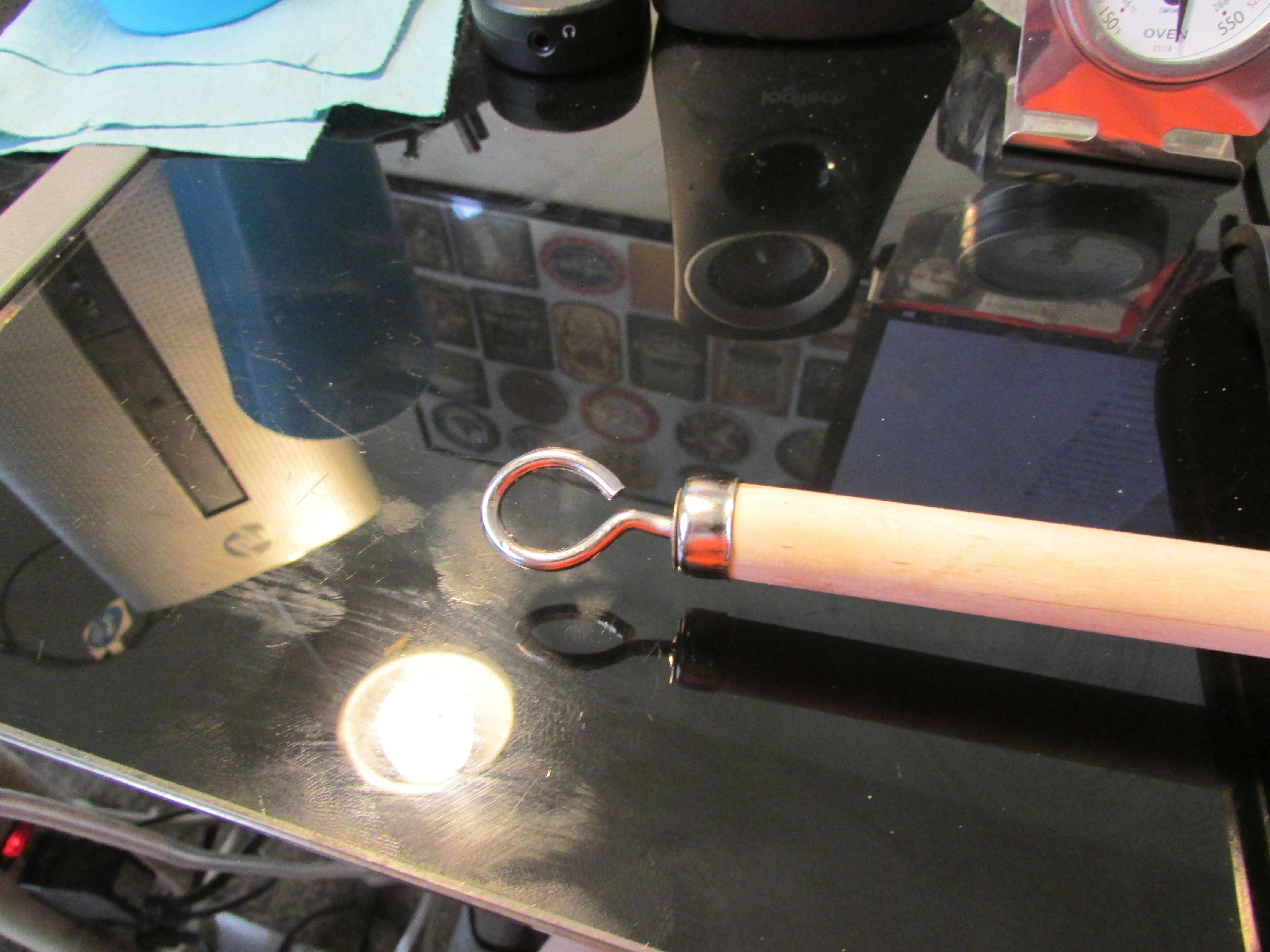

well, this past weekend was it. No more BS, this thing is gonna get right or else. Took it apart a fifth time Saturday to try and seal it up. Got three shots before running outta gas. literally. Sunday saw me taking it apart a fifth time, with suggestions from a fellow air gun page member on Facebook. Took apart the "new" Archer gas valve-which turns out is another style revision from Crosman. The light corrosion on the stem must've been making it stick open? Polished it with a green Scotchbrite pad. Did the same with the cocking and hammer pistons, as they had oily varnish stained all over them. Oiled everything up for reassembly with Pellgun oil, per Crosman tech's suggestion. Unscrewed the two parts of the gas valve a turn or two, oiled the seal, and pushed it down the tube into place. Then used my " dressing stick" with a hook eye on the end I modded to screw the housings together again to push the seal out against the gas tube walls. Getting it all back together, I oiled two Co2 cartridges and slid them in, tightening the piercing cap in place. Worked the bolt, then trigger. Leaked gas ever so slightly, then quickly worked the bolt to stop it. Shot 10 Beeman silver bear .22's @ 12.65gr at the 10M target. No more leaks. Blew out the bull's eye. Three holes at the bottom of the target are from Saturday's failed attempt. Here's a few pics to show what I've been on about;

Happy as a clam that it's still holding gas as of now! Shoots harder, sounds a bit louder, but it works great finally! I also got the scope in a better position for improved eye relief, since cross hairs are a bit clearer now. I can also now easily use my thumb and forefinger to roll a pellet into the open breech.

Happy as a clam that it's still holding gas as of now! Shoots harder, sounds a bit louder, but it works great finally! I also got the scope in a better position for improved eye relief, since cross hairs are a bit clearer now. I can also now easily use my thumb and forefinger to roll a pellet into the open breech.

Upvote 0

I'm wondering if the stock is actually walnut. Because when I used the same Minwax Gunstock stain on a trial piece of beech wood, it looks nowhere near as nice as yours does.

Looks excellent, BTW!

Looks excellent, BTW!

Upvote 0

G

Guest

Guest

Actually found out from a fellow Facebook air rife page member that in the 50's when I was a little feller, Elm, which has grain lot like oak, was dirt cheap and widely used. Including by Crosman. So it's very likely Elm. I also finished another Episode of Airgun Shooter where I retest 6 different pellets through the old girl and my Caldwell deluxe chronograph. She gave some surprises after finally sealing up, however. But it was great getting to the final phase of this restoration. The shooting part is gratifying!

Upvote 0

G

Guest

Guest

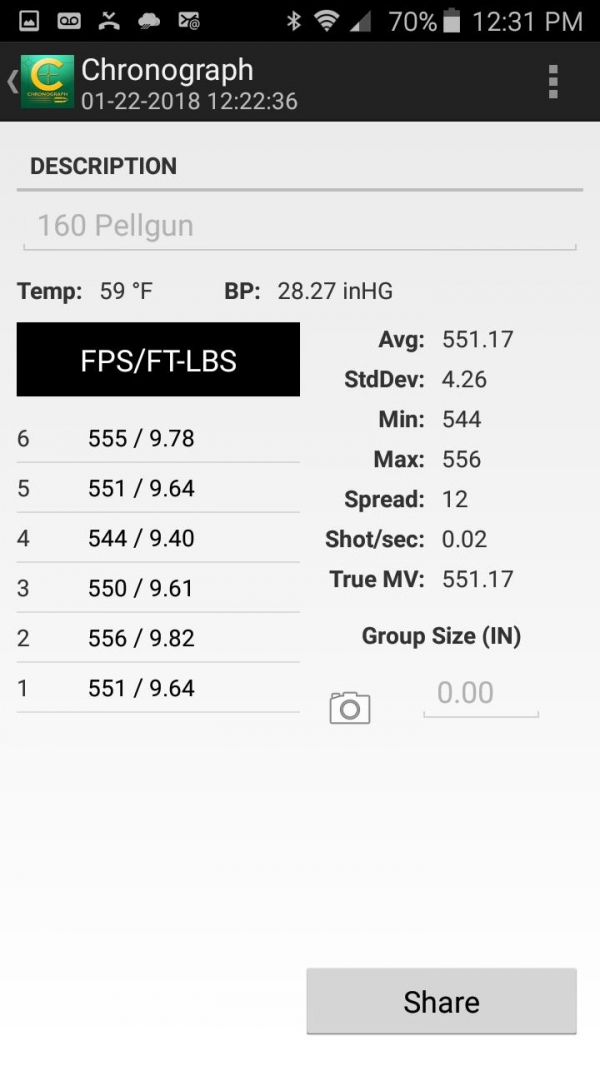

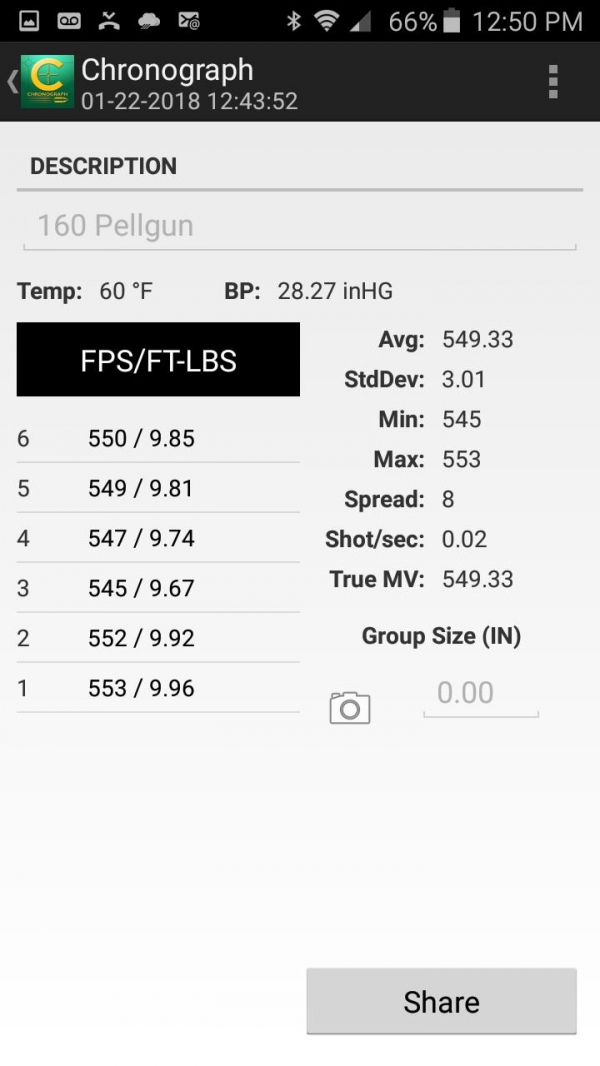

Okay, finally a couple updates! On retiree payday, I'm ordering the Archer QB78 XP tuned valve he says will fit. Says it's good for 70FPS, so we'll see? And after looking at the 160 Pellgun's chronograph folder, I noticed a few pellets I hadn't tested? So I tested the CPHP's, .22ca;, 14.3gr. Then the H&N FTT @ 14.66gr, and surprise! the H&N hornet @ 16.2gr. I do think, buy looking at the numbers, I hadn't cleaned it after last session? Anyway, here's some chronograph numbers;

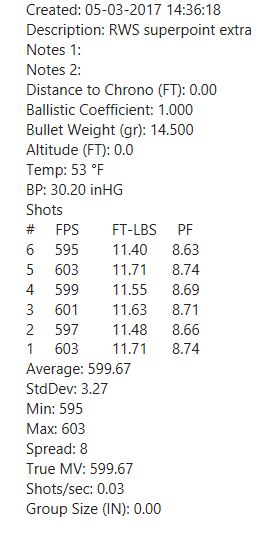

RWS superpoint Extra, 14.5gr;

CPHP @ 14.3gr;

H&N FTT @ 14.66gr;

H&N hornet @ 16.2gr;

RWS superpoint Extra, 14.5gr;

CPHP @ 14.3gr;

H&N FTT @ 14.66gr;

H&N hornet @ 16.2gr;

Upvote 0

G

Guest

Guest

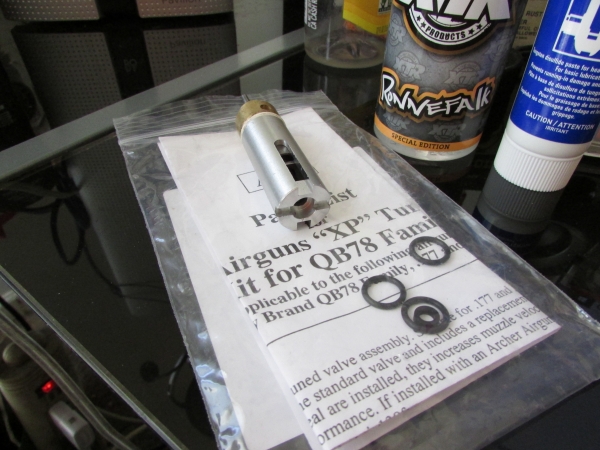

Well, the barrel was definitely filthy, so I cleaned it up for a retest. After I install this Archer XP-Tuned gas valve assembly! It's supposed to be worth another 70FPS! So the 660 it does now should go up to as much as 730FPS?! The valve is the 1963 Crosman redesign reworked 6-ways from Sunday...

Upvote 0

G

Guest

Guest

I test 3 new pellets in my Crosman 160 Pellgun variant 1 with gas valve upgrade in this episode, part 1 Crosman 160 Chrono tests/valve upgrade PT1 of Airgun Fan!

https://www.youtube.com/watch?v=ilcwtG5F-XA&feature=youtu.be

https://www.youtube.com/watch?v=ilcwtG5F-XA&feature=youtu.be

Upvote 0

G

Guest

Guest

Whew! Had to dig back some 22 pages to find this! I finally installed the Archer XP-Tuned gas valve in the 160 Pellgun. Unfortunately, my chronos went south. Need money for new G2...

http://www.youtube.com/watch?v=sIGN86-07Gk

http://www.youtube.com/watch?v=sIGN86-07Gk

Upvote 0