By way of follow up, I have had the filter with the mods in place for about 5.7 hours now. For details on the runs you can see my log here:

https://docs.google.com/spreadsheets/d/1oygaCsqJRjNGGTpXGPIYnAU1ZkyqWbBh5Tz7ODzHb24/edit?usp=sharing

As you will see I had a couple of issues, unrelated to the filter, but I have been able to make the corrections and all is working fine now.

I did a 900psi top off into my 44cf tank yesterday. Today I opened up the filter to examine the interior of the filter tube, the PVC, o-rings, tampons and the 13x Zeolite.

Once the PVC tube was extracted from the tube, my first observation is that the o-rings are till in place, and showing some signs of compression against the face of the caps.and PVC ends.

The tampons show no evidence of water staining. Shaking the pvc, no sound of moving granules is heard, so it is still packed as tightly as it was when placed inside.

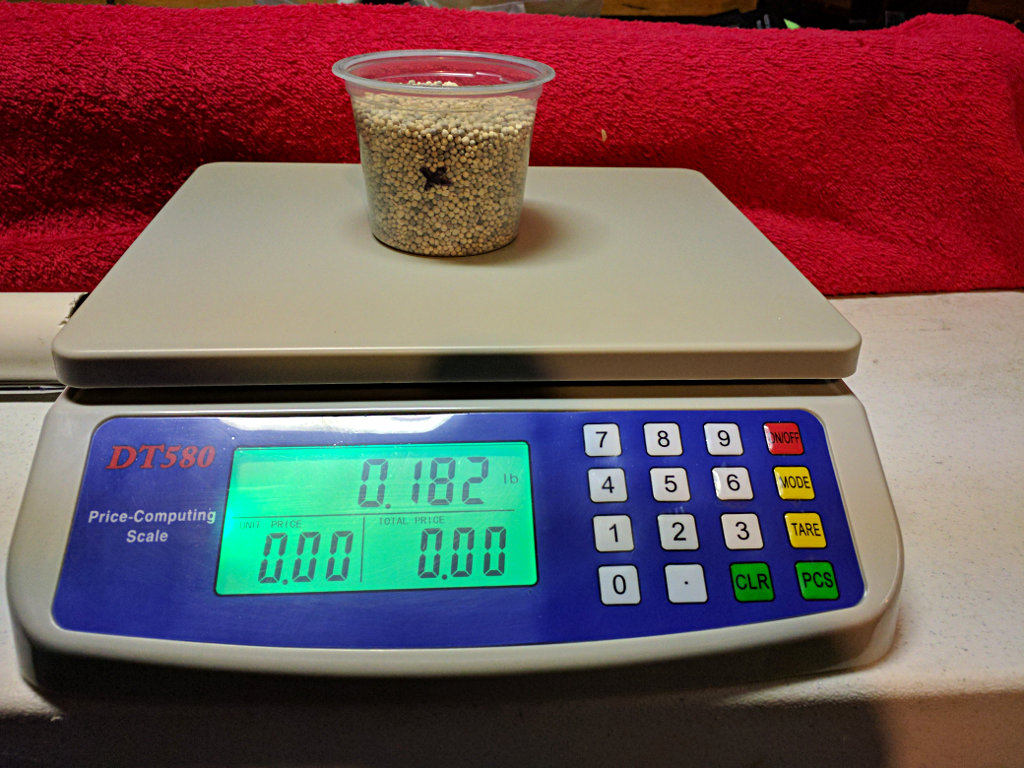

Not having a proper scale, I improvised a simple balance. I dumped the "used" zeolite into one of two identical containers. In the other I placed fresh Zeolite, matching as closely as possible the volume of the used container. Placing them on the balance showed that the used material was slightly heavier.

The inside of the filter tube was pristine, no signs of any adverse processes.

Fully acknowledging the less than scientific methodology, I am still pleased. The o-rings were in place and are showing signs of compression, the tampons also held their position, and I believe that the weight difference probably demonstrates that the used material was holding moisture.

Six hours does not make for much of a trial, but before I went too far, I wanted to check things out. I put all of the same components back into the filter and will extend their run for a bit to see how things look. In future trials I will weigh the Zeolite prior to use so that I have a baseline that might yield a more definitive result.

Submitted for what it is worth....thanks for reading.

https://docs.google.com/spreadsheets/d/1oygaCsqJRjNGGTpXGPIYnAU1ZkyqWbBh5Tz7ODzHb24/edit?usp=sharing

As you will see I had a couple of issues, unrelated to the filter, but I have been able to make the corrections and all is working fine now.

I did a 900psi top off into my 44cf tank yesterday. Today I opened up the filter to examine the interior of the filter tube, the PVC, o-rings, tampons and the 13x Zeolite.

Once the PVC tube was extracted from the tube, my first observation is that the o-rings are till in place, and showing some signs of compression against the face of the caps.and PVC ends.

The tampons show no evidence of water staining. Shaking the pvc, no sound of moving granules is heard, so it is still packed as tightly as it was when placed inside.

Not having a proper scale, I improvised a simple balance. I dumped the "used" zeolite into one of two identical containers. In the other I placed fresh Zeolite, matching as closely as possible the volume of the used container. Placing them on the balance showed that the used material was slightly heavier.

The inside of the filter tube was pristine, no signs of any adverse processes.

Fully acknowledging the less than scientific methodology, I am still pleased. The o-rings were in place and are showing signs of compression, the tampons also held their position, and I believe that the weight difference probably demonstrates that the used material was holding moisture.

Six hours does not make for much of a trial, but before I went too far, I wanted to check things out. I put all of the same components back into the filter and will extend their run for a bit to see how things look. In future trials I will weigh the Zeolite prior to use so that I have a baseline that might yield a more definitive result.

Submitted for what it is worth....thanks for reading.

Upvote 0