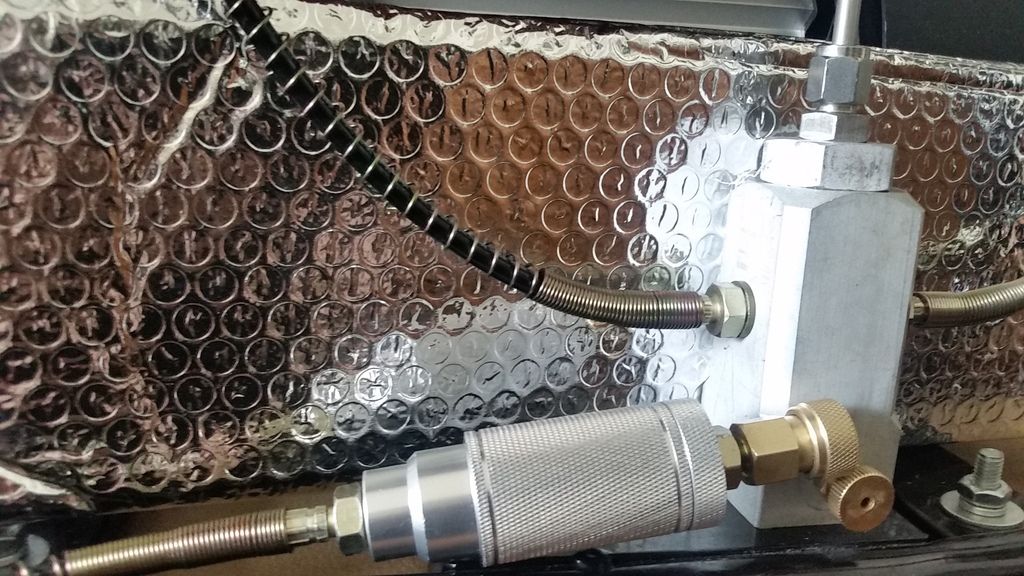

The oil isn't that huge of a deal. The box is absolutely soaked and the unit has quit a bit on it but i cleans up quick, and it looks to be nice clean oil. I had seen Ethers video on the unboxing so it wasn't a huge surprise. As for the wires, same deal, one of them was the power, The crimp came off the spade connector at the plug, once again not a huge deal, I think I'll solder both of them. The bigger deal was that I did spring for the automatic shutoff upgrade, and there are a couple of components wired and connected to the top of the unit, it looks like a big and a small breaker next to one another, both of those were hanging free, and a number of wires were disconnected or pulled free.

I do have to say though, I sent an email off to Michael last night around 10 his time, and I had a response first thing this morning. So as far as that is concerned i'm pretty happy.. So I will call him later today and see what we can get figured out. The problem is I think one of the breakers broke it's mounting bracket, and also I'm not sure where some of the wires are supposed to reconnect.

Ether: Yeah in the video they say, that they asked for the compressors to come empty from the distributor or whatever, but they still are not, and that when the compressors arrive they have all different levels of oil, some too much, some too little. In Michaels e-mail back to me, he says that more than likely the oil spills came when the units were shipped to them, and that once they get them and test them, they drain them of oil to ship to us.