Had time this week to work on my pellet sizer. If your a little handy you could save a little money doing it this way. If you have to add in the cost of a lathe It may not pay to do it this way..... : ) I made this one out of aluminum but the rest I think I will make them out of steel. This one was just a test to see if I could remember how to run the lathe... : ) Its far from perfect but usable. If your a machinist please don't laugh to much.... : ) I'm just learning here. I had some aluminum around so I used it for my platform to hold .... 2 Neck die sizing bushings .253 and .254 . These sizes were perfect for the slug I put through the barrel. I will have to figure out how to make my own for other sizes I want to try they weren't readily available. They were cheap and should do a good job. Here is some pic of what I have done so far.

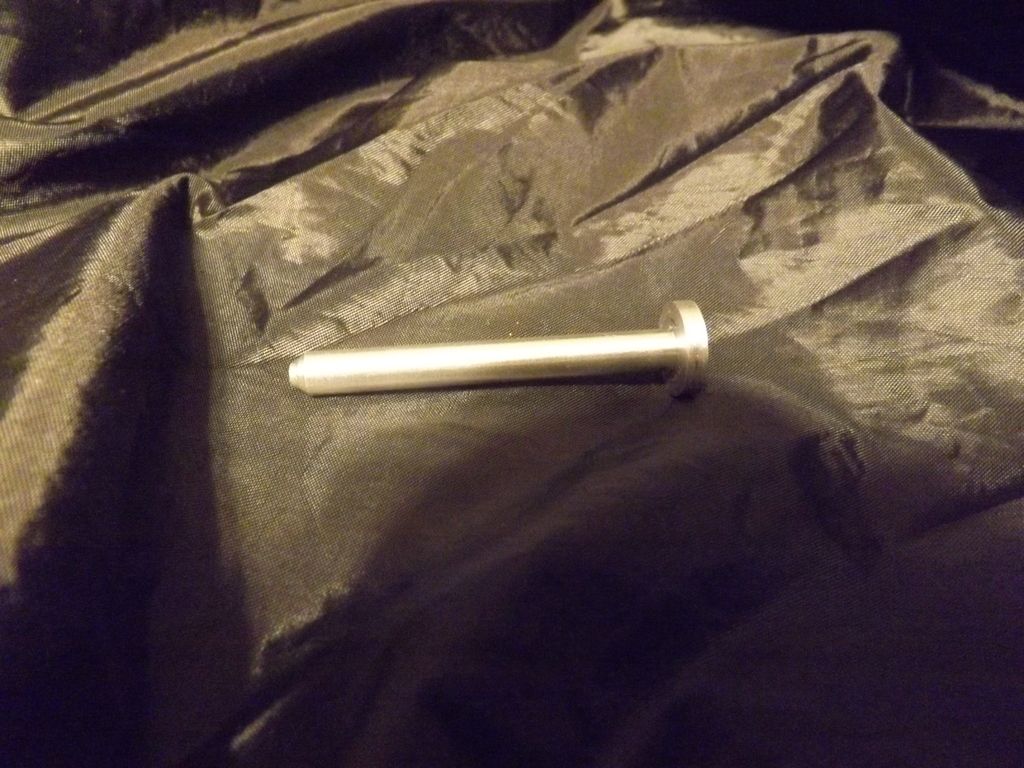

This is the holder I built.

I'm not sure if will epoxy it into the holder or use set screws?

So I have around 17 bucks per sizer If I make one more holder or a little less If I use set screws and just change from each size. If you have any coments positive or negative I would like to hear them.

Have a great one....

Richard

This is the holder I built.

I'm not sure if will epoxy it into the holder or use set screws?

So I have around 17 bucks per sizer If I make one more holder or a little less If I use set screws and just change from each size. If you have any coments positive or negative I would like to hear them.

Have a great one....

Richard