A few have recently asked how I maintain good accuracy using the RWS ZR Bullseye (and clone) mounts. I take no credit for this method. I initially saw these being made by Hector Medina, and his are much more finely executed.

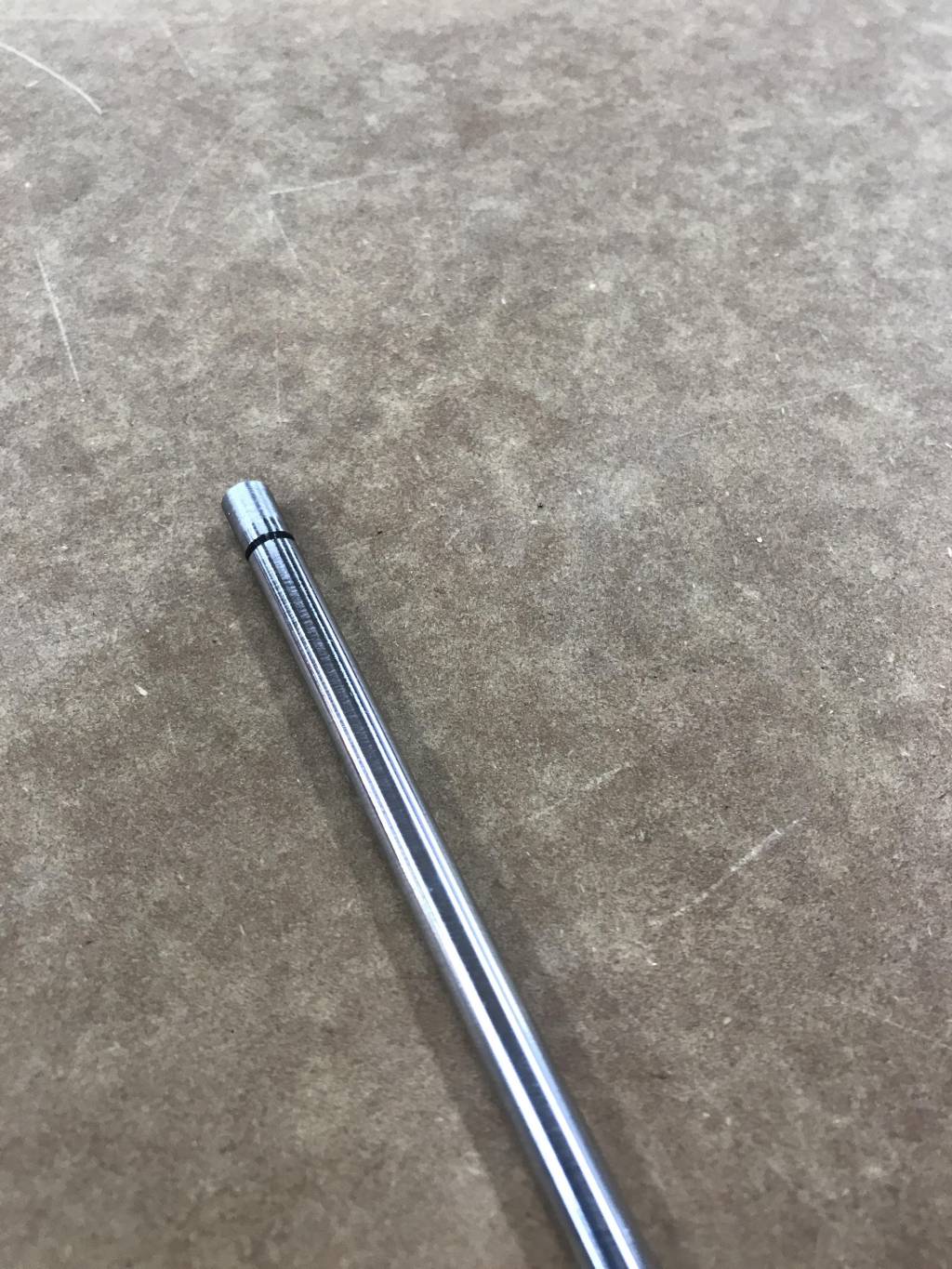

Here is what I have done to eliminate the slop in the mechanism. Basic home jobber hackery. The pictures are in no particular order. I used a drill press but it can easily be done with a hand drill as well. It sounds odd but I tap the holes with a metric tap and use imperial nylon bolts. This creates an intentional cross thread. It only deforms the sacrificial plastic bolt and ensures they won't back out. I have MANY rounds on a few of these and have never needed to re-adjust them thus far. I tighten the bolt until it just begins to bind on the slide and then back it out until the mechanism moves freely without any remaining slop then cut off the excess of the bolt with a utility knife or razor blade. One bolt can do all 4 holes. One corner is probably enough but I usually do them on all 4 of the rear corners like this one shows while I have it apart. I have seen others do this to both ends but in my usage, I have found there is no need to do this to the front since the front is located by a conical sleeve and post which is very repeatable even if you feel movement. While I have them apart I usually polish the rods and the inside of the bores just to make it all run more smoothly. These will absolutely allow you to run a fragile scope on a magnum springer without damage. I have never hurt a scope using this method and I haven't heard of anyone who has.

The biggest issue with these is that there is not much room between the top of this mount and the bottom of the rings. Not all scopes will fit. Any scope with a large under belly or a large nitrogen fill nipple under the turret housing will interfere. These are nothing special and the cheap ones from amazon or eBay are just as good/bad as the official units. Unfortunately, I have found no other commercially available solution available. Be aware I have had to lap the rings in order to get a good fit even on new units. You may be better off buying 2 and swapping parts as needed just in case.

It really is a shame that we have to re-work brand new mounts just to make them serviceable. I would love to see someone on here create a sliding intermediate mount. Dovetail on the bottom to fit our springers and Picatinny on the top to fit the most common rings/mounts. I know we have many machinists here and this is certainly needed. I would think that a person could sell as many as they chose to make at a price commensurate with the quality of the unit/materials.

Here is what I have done to eliminate the slop in the mechanism. Basic home jobber hackery. The pictures are in no particular order. I used a drill press but it can easily be done with a hand drill as well. It sounds odd but I tap the holes with a metric tap and use imperial nylon bolts. This creates an intentional cross thread. It only deforms the sacrificial plastic bolt and ensures they won't back out. I have MANY rounds on a few of these and have never needed to re-adjust them thus far. I tighten the bolt until it just begins to bind on the slide and then back it out until the mechanism moves freely without any remaining slop then cut off the excess of the bolt with a utility knife or razor blade. One bolt can do all 4 holes. One corner is probably enough but I usually do them on all 4 of the rear corners like this one shows while I have it apart. I have seen others do this to both ends but in my usage, I have found there is no need to do this to the front since the front is located by a conical sleeve and post which is very repeatable even if you feel movement. While I have them apart I usually polish the rods and the inside of the bores just to make it all run more smoothly. These will absolutely allow you to run a fragile scope on a magnum springer without damage. I have never hurt a scope using this method and I haven't heard of anyone who has.

The biggest issue with these is that there is not much room between the top of this mount and the bottom of the rings. Not all scopes will fit. Any scope with a large under belly or a large nitrogen fill nipple under the turret housing will interfere. These are nothing special and the cheap ones from amazon or eBay are just as good/bad as the official units. Unfortunately, I have found no other commercially available solution available. Be aware I have had to lap the rings in order to get a good fit even on new units. You may be better off buying 2 and swapping parts as needed just in case.

It really is a shame that we have to re-work brand new mounts just to make them serviceable. I would love to see someone on here create a sliding intermediate mount. Dovetail on the bottom to fit our springers and Picatinny on the top to fit the most common rings/mounts. I know we have many machinists here and this is certainly needed. I would think that a person could sell as many as they chose to make at a price commensurate with the quality of the unit/materials.