This is a weird problem. When I charge the gun to 200 bar, I can hear a small air leak, but it only leaks until the gauge pressure reaches 160 bar., then it stops. I can then shoot about 25 rounds until the gauge falls into the yellow and I am off the regulator. I cannot find the leak. It will hold the 160 bar fill for days on end.......no leaks. However, this is the second gun with the same problem. The first I gave back to the dealer under guarantee and when it came back from depot repair (Belgium), it had the same fault except worse. The dealer then gave me a replacement. I have been living with it for a year. The gun shoots fine. I really like it. I don't want to send it in again for repair for fear it will be trashed. I'm prepared to take it apart myself, but I would like a heads up on what this issue is. Has anyone else had this issue? I suspect the tank is swelling under pressure and that is causing the o ring to leak. I would like to hear anyone else's guess before I take it apart.

- The AGN App is ready! Search "Airgun Nation" in your App store. To compliment this new tech we've assigned the "Threads" Feed & "Dark" Mode. To revert back click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning PP700SA unable to hold air charge at 200 bar

- Thread starter steve-l

- Start date

There are quite a few places these guns can leak from. It is well known that they don’t come with good orings. When I first got my pistol years ago, I replaced them all with quality orings and a quality reg. Later on I had a leak issue that took a while to find. It was a imperfection from the factory that just took a while to rear its ugly head. I was able to polish it out and haven’t had to touch the gun for more than a year. If you feel you have to send a Chinese PCP back every time there is a problem, you might as well put the people at your post office on your Christmas list. You will become very well acquainted. Take it apart and put some good orings in it. I listed them on this forum years ago.

Upvote 0

I have a couple videos that might help you. These guns are super easy to take apart and put back together. Just go slow and you will be good.

https://youtu.be/xTLmrAZbrHI

https://youtu.be/Hnh2yxmb_bw

https://youtu.be/xTLmrAZbrHI

https://youtu.be/Hnh2yxmb_bw

Upvote 0

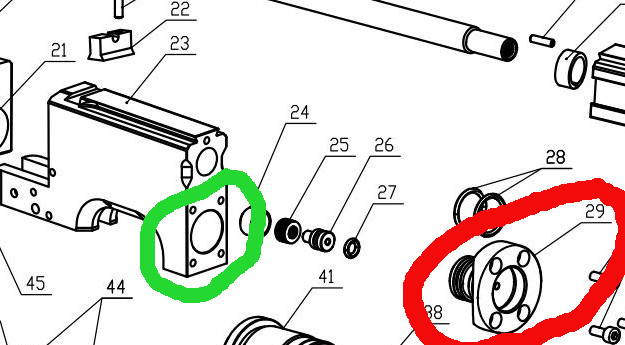

Here's a possible leak point that does NOT have an o-ring but, in your case, may need one. I know because i added one and the leak went away.

I've been in and out of the gun several times, it's easy.

Between parts 29 and 24 add an o-ring, possible leak point. On part 24 I placed an oring on the surface where the four holes are drilled to secure the "constant valve". The oring should fit snugly over the male thread on the Constant Valve that is inserted into the receiver... the big hole on part 24 in the center of the four threaded holes.

I've been in and out of the gun several times, it's easy.

Between parts 29 and 24 add an o-ring, possible leak point. On part 24 I placed an oring on the surface where the four holes are drilled to secure the "constant valve". The oring should fit snugly over the male thread on the Constant Valve that is inserted into the receiver... the big hole on part 24 in the center of the four threaded holes.

Upvote 0

This is the only place I added an oring that the gun didn’t come with.

I didn't know about that one, Thanks. Mine has zero leaks.

Upvote 0

JohnyPDX,

That sounds about right. I'll source some rings and report back.....thank you. How did you install that O ring? Did you place it in the bore first or on the end of 29?

That sounds about right. I'll source some rings and report back.....thank you. How did you install that O ring? Did you place it in the bore first or on the end of 29?

Upvote 0

The symptom describes an O-ring that is either too soft or it has a small defect like a small bite taken out of it. So it almost withstands 200 bar but not quite. Then once it leaks down to 160 bar, the O-ring resists deforming by enough to hold the pressure.

Finding it is the fun part. And by fun I mean like a proctology exam.

Finding it is the fun part. And by fun I mean like a proctology exam.

Upvote 0

JohnyPDX,

That sounds about right. I'll source some rings and report back.....thank you. How did you install that O ring? Did you place it in the bore first or on the end of 29?

Slipped over the 'male' piece of part 29 and then seals against the flat area of part 24. If that doesn't make sense PM me. The force squished the oring out to the edge, it ain't pretty, but it works.

Upvote 0

JohnyPDX,

That sounds about right. I'll source some rings and report back.....thank you. How did you install that O ring? Did you place it in the bore first or on the end of 29?

Slipped over the 'male' piece of part 29 and then seals against the flat area of part 24. If that doesn't make sense PM me. The force squished the oring out to the edge, it ain't pretty, but it works.

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

Upvote 0

JohnyPDX,

That sounds about right. I'll source some rings and report back.....thank you. How did you install that O ring? Did you place it in the bore first or on the end of 29?

Slipped over the 'male' piece of part 29 and then seals against the flat area of part 24. If that doesn't make sense PM me. The force squished the oring out to the edge, it ain't pretty, but it works.

So you are using an oring as a gasket.

Successfully

Upvote 0

Regarding the O-ring pictured, it is not installed by the factory because the sealing is normally done by torqueing down onto the white plastic disc inside the regulator. The problem is, if you ever take it apart, it is difficult to develop enough torque to make it seal again. Adding the O-ring is a very simple fix that prevents it from leaking. Easy peasy, right?

Except that’s not the whole story. Yes it keeps you from losing pressure but now the pressure building up inside represents a potential source of creep. High pressure in the reservoir can slowly migrate around the disc and to the output side of the regulator. Just depends on how well each side of the disc seals when you reassemble. Some have resorting to gluing the disc down with cyanoacrylate. That worked for me.

Except that’s not the whole story. Yes it keeps you from losing pressure but now the pressure building up inside represents a potential source of creep. High pressure in the reservoir can slowly migrate around the disc and to the output side of the regulator. Just depends on how well each side of the disc seals when you reassemble. Some have resorting to gluing the disc down with cyanoacrylate. That worked for me.

Upvote 0

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

No argument with your principled objection, but the sealing issue is unrelated to O-rings #28.

Upvote 0

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

No argument with your principled objection, but the sealing issue is unrelated to O-rings #28.

I had the same problem but once I discovered the imperfection in the picture I posted, I was able to fix it. Where is Johnny’s leak coming from that forced him to put a gasket on a PCP?

Upvote 0

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

No argument with your principled objection, but the sealing issue is unrelated to O-rings #28.

I replaced orings #28 and still did not achieve a seal so made it work. Don't want to send it back to Krale and I am never going to China again.

Upvote 0

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

No argument with your principled objection, but the sealing issue is unrelated to O-rings #28.

I had the same problem but once I discovered the imperfection in the picture I posted, I was able to fix it. Where is Johnny’s leak coming from that forced him to put a gasket on a PCP?

Poor design.

Upvote 0

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

No argument with your principled objection, but the sealing issue is unrelated to O-rings #28.

I replaced orings #28 and still did not achieve a seal so made it work. Don't want to send it back to Krale and I am never going to China again.

If you ever have your gun apart again, flip it upside down and see if your gun doesn’t have the same scratch coming from that tiny hole. After I replaced the #28 orings twice, I knew I had to take a much harder look. Was pissed when I saw that scratch. But then I also had to consider who built the gun.

Upvote 0

So you are using an oring as a gasket. You are masking a problem with orings #28 and their fitment into the frame. Me no likie.

No argument with your principled objection, but the sealing issue is unrelated to O-rings #28.

I replaced orings #28 and still did not achieve a seal so made it work. Don't want to send it back to Krale and I am never going to China again.

If you ever have your gun apart again, flip it upside down and see if your gun doesn’t have the same scratch coming from that tiny hole. After I replaced the #28 orings twice, I knew I had to take a much harder look. Was pissed when I saw that scratch. But then I also had to consider who built the gun.

Ok cool, next time I'll look at 10x and fix it. I hated adding the o-ring but I was pissed and problem solving it.

Upvote 0

It was like someone at the factory took a scribe, made the scratch, looked at his buddy and said this will keep some poor sucker busy chasing this leak.

Upvote 0