Before a bunch of you tell me that all these mods are not needed for the YH to run properly, let me say I already know that and that I like making parts and modding stuff. Im doing it for the fun of it, not because the YH needs it (well maybe it needs it a little bit).

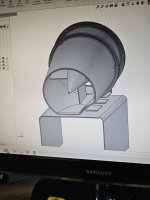

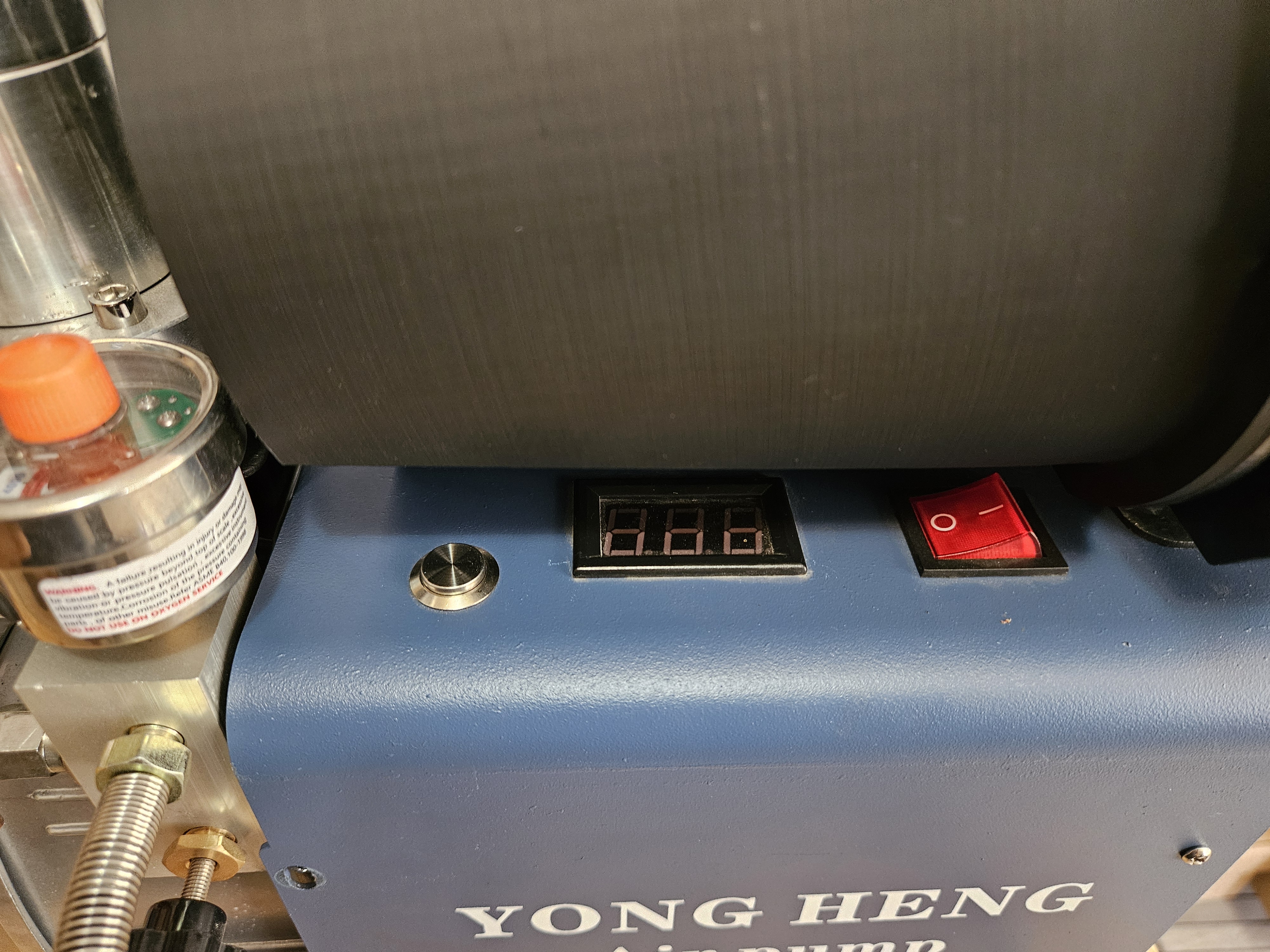

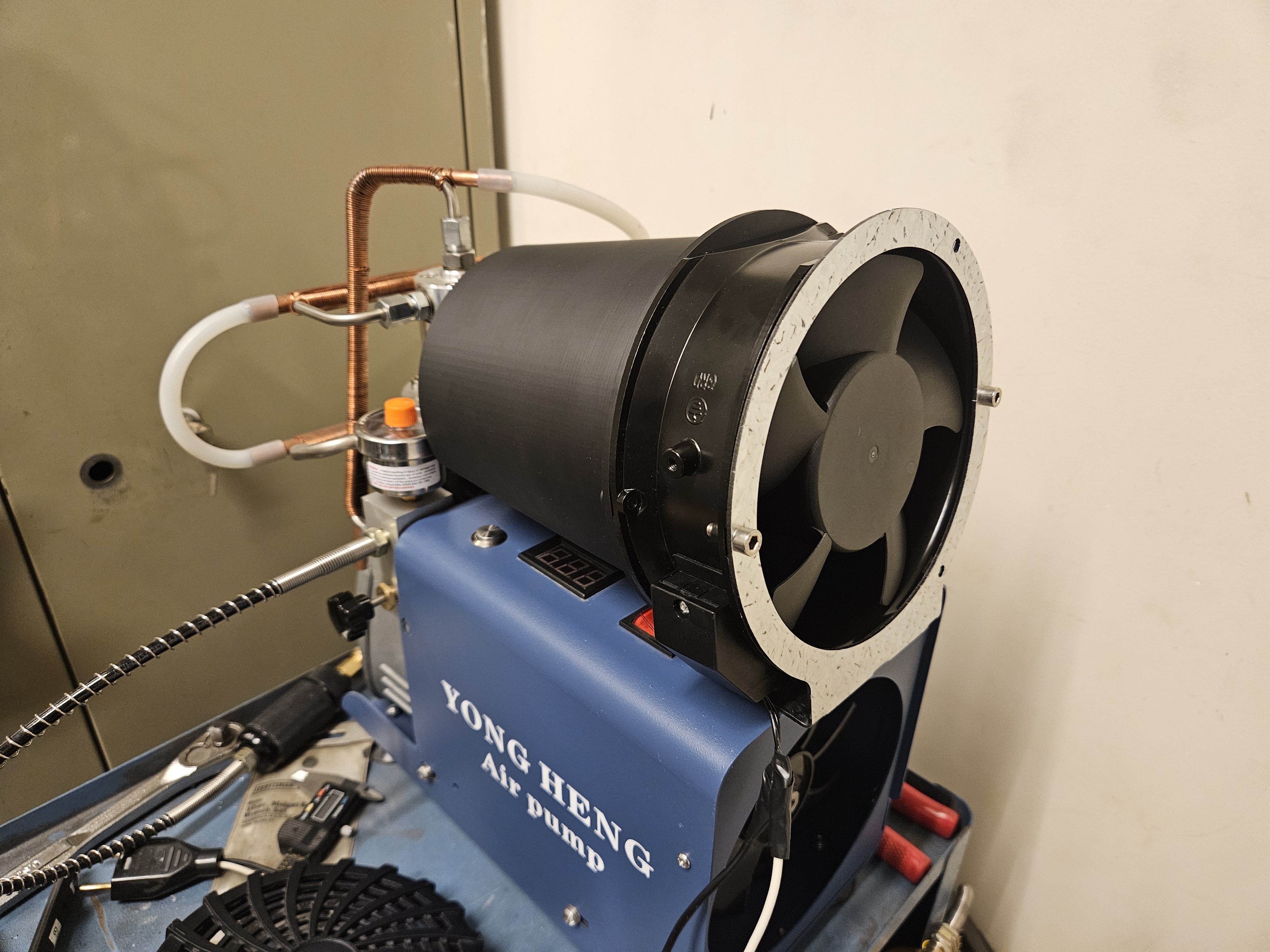

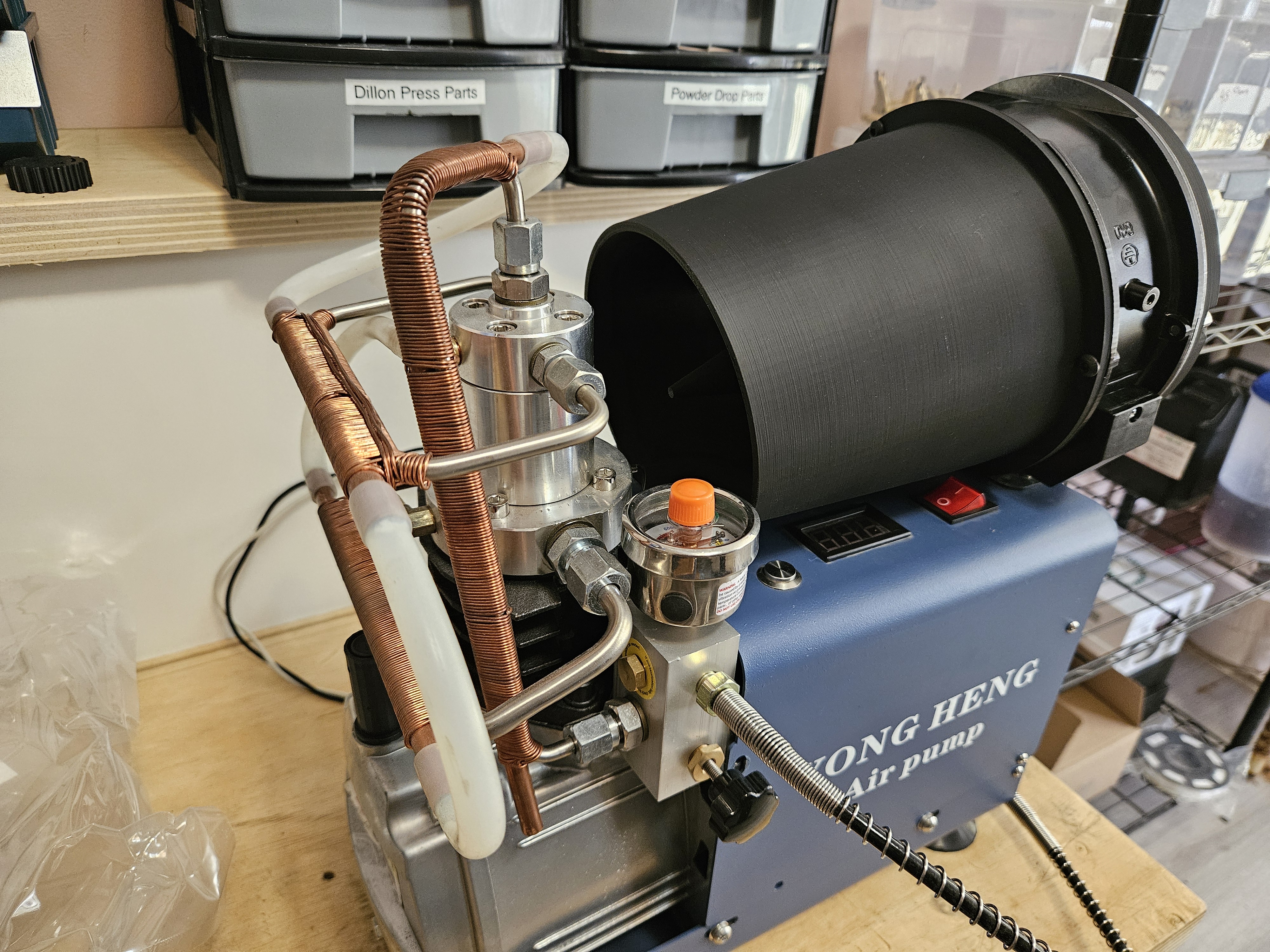

So I bought a pretty strong fan on Ali Express to help cool the head and I had to mount it so I cut out a laser cut mount for it. It uses the same screws that holds the case of the YH so no need to drill anything. Then I noticed the fan was throwing the wind pretty much anywhere but forward so I made a duct for it to focus the stream of air on the second stage . I also moded the duct a little on the bottom so I would still have access to the thermometer and the buttons. Then, after Id touched the fan a couple of time by mistake while it was running, I printed out a grill to protect my fingers from getting caught in the blade.

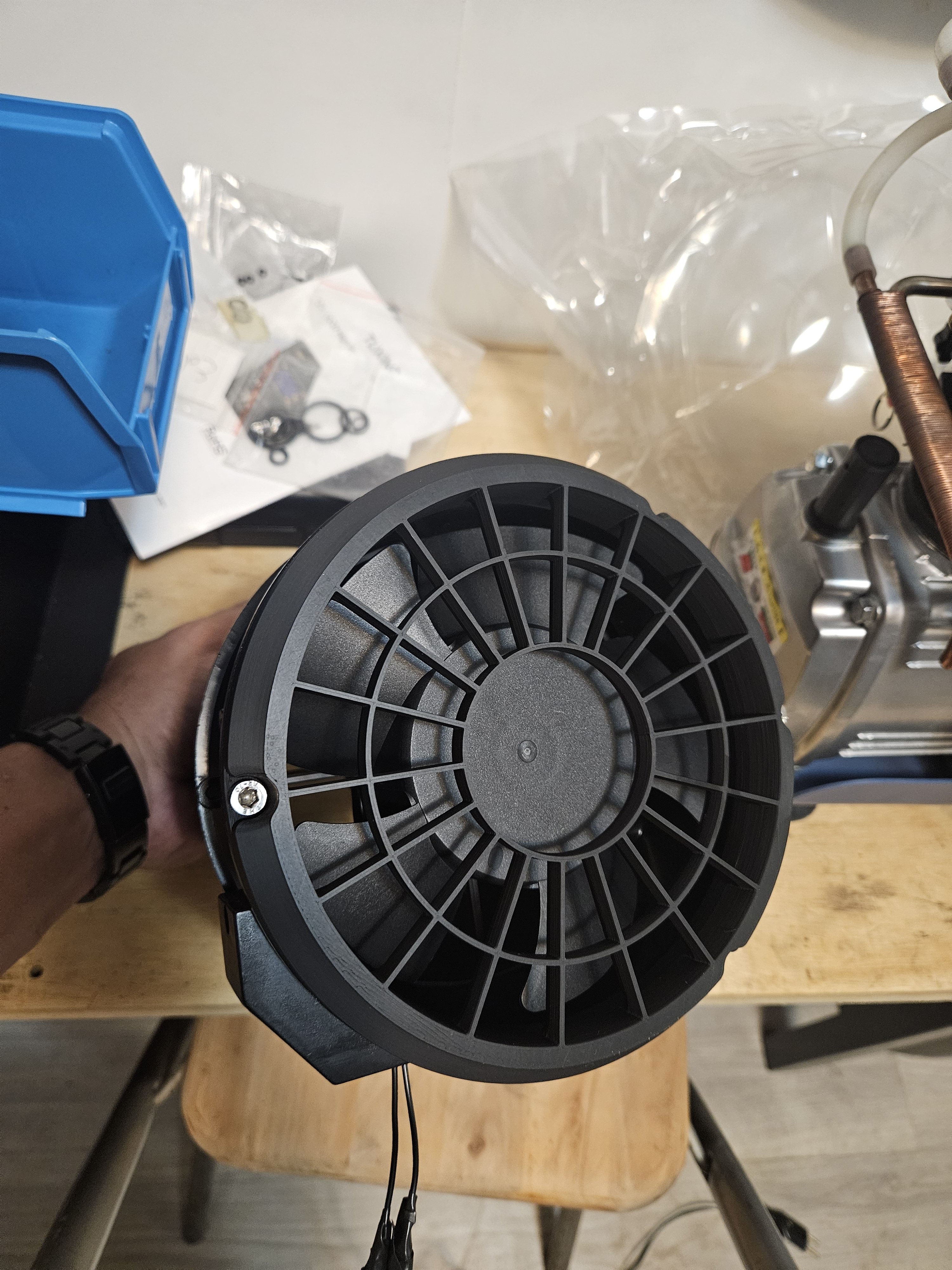

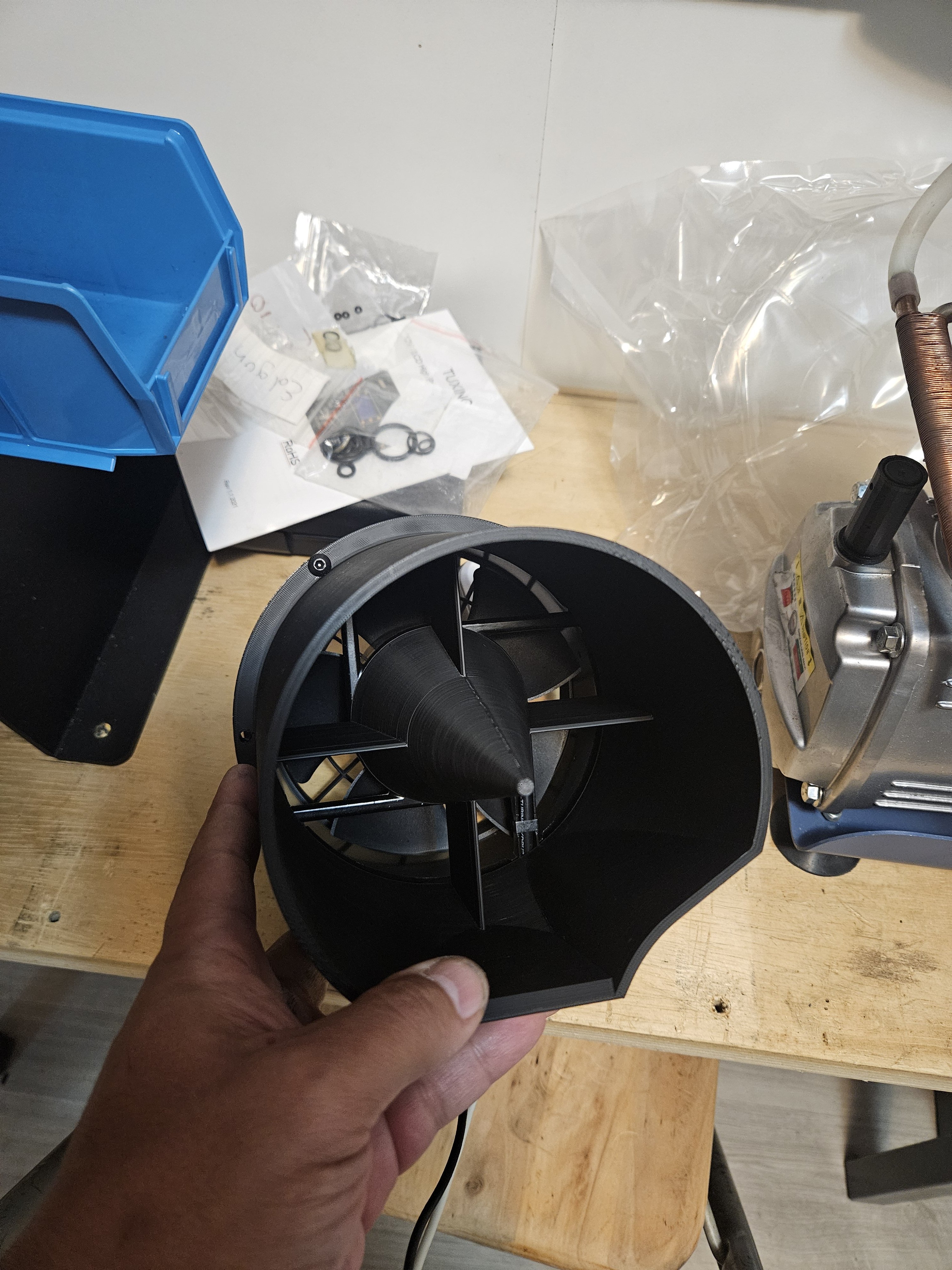

Another couple little things I did was replace the straight bladed centrifugal fan that came with the unit with an axial, more effective one from Ali Express. I also modified the original grill by removing all of the concentric supports (first picture) and now the internal airflow is a lot better than before.

Oh and a little detail that I was not sure was going to work as I was designing the duct was I gave the duct a flat bottom and a little chamfer to help pull the wind down and direct it to help cool the first stage cylinder. You can see it on the second to last picture, right under my thumb. It really does help quite a lot better than I expected, with just the top fan on you can feel the stream of air going right around the cast iron fins. Much better than the original design.

Dont mind the wiring, I`ll tidy it all up after the testing is done. BTW, all parts were printed in ABS, not PLA, so if things get hot the ABS should be able to handle it just fine.

So I bought a pretty strong fan on Ali Express to help cool the head and I had to mount it so I cut out a laser cut mount for it. It uses the same screws that holds the case of the YH so no need to drill anything. Then I noticed the fan was throwing the wind pretty much anywhere but forward so I made a duct for it to focus the stream of air on the second stage . I also moded the duct a little on the bottom so I would still have access to the thermometer and the buttons. Then, after Id touched the fan a couple of time by mistake while it was running, I printed out a grill to protect my fingers from getting caught in the blade.

Another couple little things I did was replace the straight bladed centrifugal fan that came with the unit with an axial, more effective one from Ali Express. I also modified the original grill by removing all of the concentric supports (first picture) and now the internal airflow is a lot better than before.

Oh and a little detail that I was not sure was going to work as I was designing the duct was I gave the duct a flat bottom and a little chamfer to help pull the wind down and direct it to help cool the first stage cylinder. You can see it on the second to last picture, right under my thumb. It really does help quite a lot better than I expected, with just the top fan on you can feel the stream of air going right around the cast iron fins. Much better than the original design.

Dont mind the wiring, I`ll tidy it all up after the testing is done. BTW, all parts were printed in ABS, not PLA, so if things get hot the ABS should be able to handle it just fine.

Last edited: