I cast a lot of bullets to feed my .58 pistol. One of my favorite rounds is the round ball. the bummer is that darned sprue is hard to line up so it points straight backwards. Well, not anymore. I always wanted to put a point on the tip of the probe, so I turned a 60 degree point on the end. I think I actually picked up a couple of FPS by doing that.

To modify the ball, you will need a drill press or mill. Clamp or vise a piece of wood or solid plastic. Chuck up a large drill or chamfer tool and put in a drill point on your material.

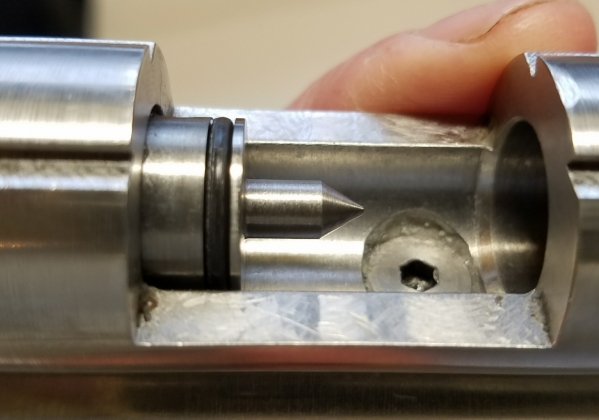

The following photo also shows a .250 diameter piece of stainless with a 60 degree point turned on it.

Now set a cast round ball into the drill point with the sprue up. line it up good and press the tool into the ball forming a small 60 degree hole in the center of the sprue.

Now your ball can easily be loaded into your gun without wondering if the sprue is going to mess up your shot. They shoot as good as any swaged round ball that you pay dearly for. Also, if your ball was always a little loose, it can be easily enlarged by pressing down just a little bit harder with your tool. Like in my case, My gun shoots really nice with .572 balls. But my mold cast exactly at .570. Making my dent as big as in the photo, it enlarges my ball to a diameter of .572. What a tack driver that pistol is....

Hope I helped somebody out there. John.

To modify the ball, you will need a drill press or mill. Clamp or vise a piece of wood or solid plastic. Chuck up a large drill or chamfer tool and put in a drill point on your material.

The following photo also shows a .250 diameter piece of stainless with a 60 degree point turned on it.

Now set a cast round ball into the drill point with the sprue up. line it up good and press the tool into the ball forming a small 60 degree hole in the center of the sprue.

Now your ball can easily be loaded into your gun without wondering if the sprue is going to mess up your shot. They shoot as good as any swaged round ball that you pay dearly for. Also, if your ball was always a little loose, it can be easily enlarged by pressing down just a little bit harder with your tool. Like in my case, My gun shoots really nice with .572 balls. But my mold cast exactly at .570. Making my dent as big as in the photo, it enlarges my ball to a diameter of .572. What a tack driver that pistol is....

Hope I helped somebody out there. John.