Hey Guys and Gals,

I have a mk2 600mm Crown in .25,great gun.

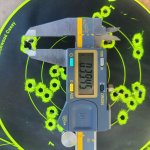

I have been noticing a change in impact that has just started. So I checked my stock screws and found they were not tight but felt as if they had started to strip out. I put some locktite medium thread locker on it, letting it dry now and no, I did not over tighten the screws, experience has taught me about over torquing screws.

I did notice a very slight movement in the action/barrel assembly and the stock, not much but any is to much.

Trying to find way this happened, the only thing I could think of is the added leverage of resting the stock on a benchrest platform. I do have a barrel band on it and a 700cc bottle. I have been using the bottle to rest the Mk2 on the stand 2 to 3 inches in front of the stock.

Any suggestion on how to resolve this issue?

The Crown shoots lights out when the stock is stabilized.

Thanks,

Mike

I have a mk2 600mm Crown in .25,great gun.

I have been noticing a change in impact that has just started. So I checked my stock screws and found they were not tight but felt as if they had started to strip out. I put some locktite medium thread locker on it, letting it dry now and no, I did not over tighten the screws, experience has taught me about over torquing screws.

I did notice a very slight movement in the action/barrel assembly and the stock, not much but any is to much.

Trying to find way this happened, the only thing I could think of is the added leverage of resting the stock on a benchrest platform. I do have a barrel band on it and a 700cc bottle. I have been using the bottle to rest the Mk2 on the stand 2 to 3 inches in front of the stock.

Any suggestion on how to resolve this issue?

The Crown shoots lights out when the stock is stabilized.

Thanks,

Mike