I have an Alkin W-31 Mariner vertical compressor and am trying to fill a SCBA tank w/ a Saber Tactical Valve. Following the Alkin instructions exactly. Start compressor w/ fill line valve closed and tank valve closed. Open fill line valve, wait until fill line gage reaches fill pressure (300 bar), then open tank valve. As soon as I open the tank valve the tank gage reads the same pressure as the fill line gage 300+/- Bar. Is that correct? I thought the tank pressure should read lower and then slowly come up.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CF tank fill problem w/ Alkin Compressor and Saber Tactical valve

- Thread starter cdog

- Start date

Try this: compressor off, bleeders open. Connect to bottle, open compressor fill valve. Open bottle valve all the way, big gauge will read bottle pressure. Start compressor and close bleeders. When compressor reaches bottle pressure, the check valve will open and bottle will fill.

My Saber Tactical valve had a loose knob, and felt like it was opening, but the knob was spinning on its threaded shaft. I added a star lock washer and all is well now.

My Saber Tactical valve had a loose knob, and felt like it was opening, but the knob was spinning on its threaded shaft. I added a star lock washer and all is well now.

Last edited:

Upvote 0

You didn't mention what your tank DH pressure is prior to filling? When you open the tank valve, you'll see the balance of compressor fill line pressure and tank pressure.I have an Alkin W-31 Mariner vertical compressor and am trying to fill a SCBA tank w/ a Saber Tactical Valve. Following the Alkin instructions exactly. Start compressor w/ fill line valve closed and tank valve closed. Open fill line valve, wait until fill line gage reaches fill pressure (300 bar), then open tank valve. As soon as I open the tank valve the tank gage reads the same pressure as the fill line gage 300+/- Bar. Is that correct? I thought the tank pressure should read lower and then slowly come up.

Upvote 0

In that case, your fill line pressure should drop to near zero as the air rushes into the tank, then slowly increase as the compressor works. It sounds as if your valve isn't opening, and what you are reading is "closed valve" pressure against the ST gauge. Does it FEEL like the valve is opening? Try turning it a couple of turns (they are designed to be low-flow as you crack the valve; I can easily control my gun fills using the ST valve). If you think it is open, and feel certain air SHOULD be going into the tank, try opening your ST bleed valve and see if air escapes.Tank is at 0 pressure.

Upvote 0

That's how I though it should be. It does feel like the valve is opening. I took the valve off and blew through the fill port with no problem. I will double check the valve handle in the morning to check what Scotty mentioned in the first post. thanks

Upvote 0

I have that same valve, and have no issue filling my 9L Great White. There is no check valve to worry about, air SHOULD flow from highest to lowest pressure, period.That's how I though it should be. It does feel like the valve is opening. I took the valve off and blew through the fill port with no problem. I will double check the valve handle in the morning to check what Scotty mentioned in the first post. thanks

Hate to ask such a silly question, but you are hooking up to the tank fill port, and not the DH fitting, right? I assume you have it right, since you said the tank gauge moved to 300 bar, just asking to make sure.

Upvote 0

Watch the stem the bottle knob is threaded onto when opening the valve. The stem should turn with the knob. When I got my ST valve, the knob was unthreading from the stem, rather than turning the stem.

Upvote 0

Gotta agree with this and what the others said. When I got my ST valve the knob was loose and would spin rather than open the valve. Had to tighten that down - along with all the other connections. My ST valve leaked like a sieve from every connection - I had to take it apart, tape each thread and then put back together.Watch the stem the bottle knob is threaded onto when opening the valve. The stem should turn with the knob. When I got my ST valve, the knob was unthreading from the stem, rather than turning the stem.

I'm wondering if what is happening is that once you have the pressure coming from the Alkin it is preventing the valve from opening and you're just spinning the handle.

I think the method you are describing for the fill is a little off though. I would never wait until the fill gauge reads 300 bar to open it up. My process is - start compressor and close bleeds, when fill gauge gets up to ~2000 psi open the fill valve handle, then open tank valve.

Because you are filling a tank from 0psi I would just keep the tank valve open and then start your fill process.

Upvote 0

@ctshooter, it makes no difference what position the compressor's fill valve handle is in during the startup process as long as the tank's valve is closed until the compressor builds pressure. The compressor has a pressure maintaining valve that doesn't release air through the hose until the compressor builds around 2K psi in the final filter housing. I connect the compressor fill hose to the tank with the fill valve lever open and open the tank valve when the hose gauge reaches 3K psi. Otherwise I follow the startup procedure the same as you do. The sequence to avoid during a top off is opening the tank valve first with the fill hose lever open before the compressor builds pressure. The hose lever seal can be damaged from the tank pressure in this circumstance.

Last edited:

Upvote 0

I had the same issue with a valve from Amazon. For some reason it wouldn't accept any more than 2500 PSI. I sent it back and now waiting one from a reputable source.

Upvote 0

It worked!

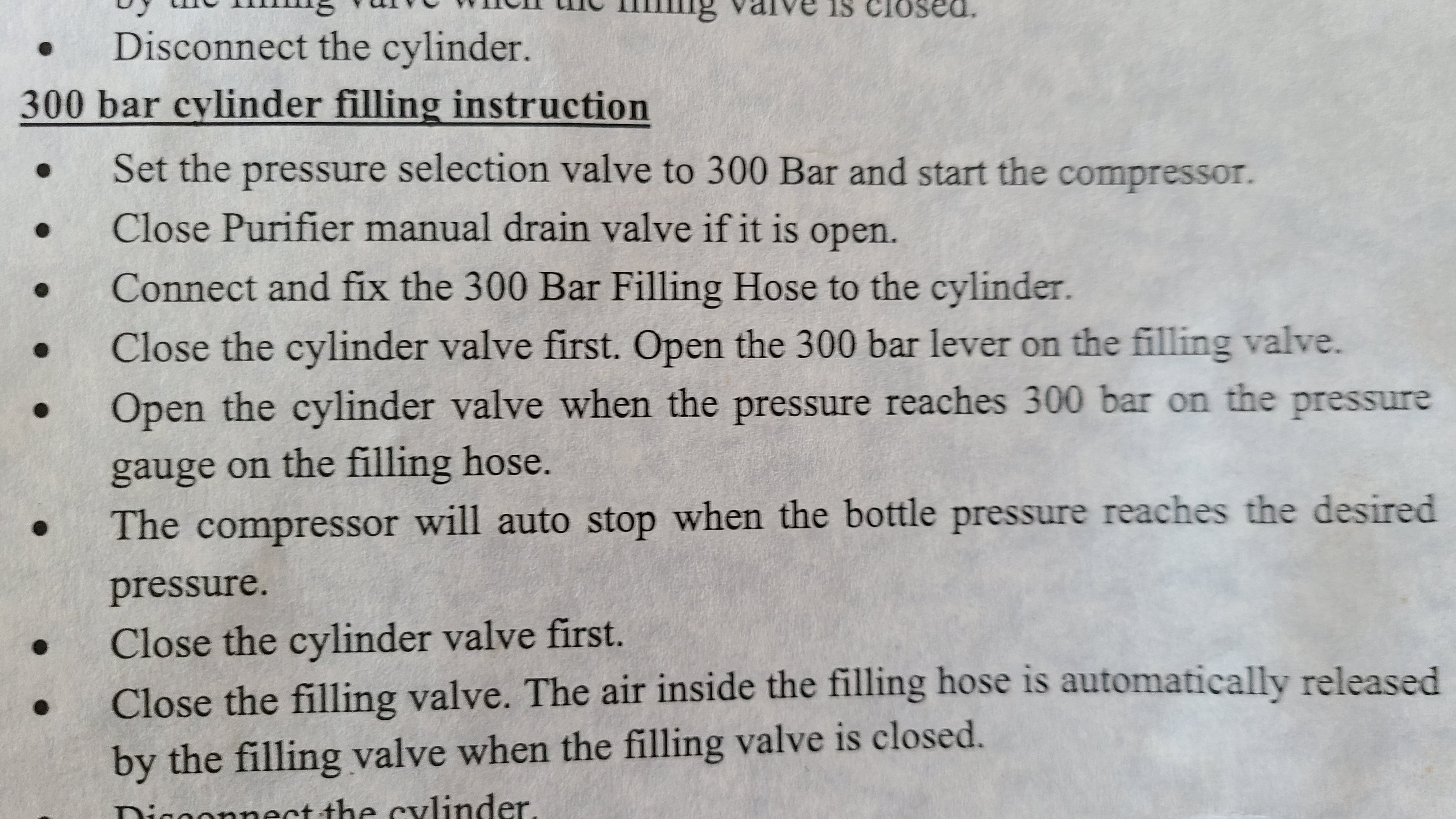

CT, Hawk, Scotty & Jim - thanks for your input. Tank valve handle was on tight. The flipping operating manual is wrong. As you can see below it says to open the cylinder valve when the gage on the fill line reaches 300 bar. I believe that CT is correct in stating that you don't want to open the tank valve until the hose pressure matches the tank pressure, otherwise you're pushing air the wrong way. Thanks again for the help.

CT, Hawk, Scotty & Jim - thanks for your input. Tank valve handle was on tight. The flipping operating manual is wrong. As you can see below it says to open the cylinder valve when the gage on the fill line reaches 300 bar. I believe that CT is correct in stating that you don't want to open the tank valve until the hose pressure matches the tank pressure, otherwise you're pushing air the wrong way. Thanks again for the help.

Upvote 0

That is correct - the idea is - it’s better for the working compressor to not slam up against a huge “X” psi but rather be able to gradually “meet” ambient pressure in the vessel you are charging so your not overworking your compressor.It worked!

CT, Hawk, Scotty & Jim - thanks for your input. Tank valve handle was on tight. The flipping operating manual is wrong. As you can see below it says to open the cylinder valve when the gage on the fill line reaches 300 bar. I believe that CT is correct in stating that you don't want to open the tank valve until the hose pressure matches the tank pressure, otherwise you're pushing air the wrong way. Thanks again for the help.

View attachment 448647

Upvote 0