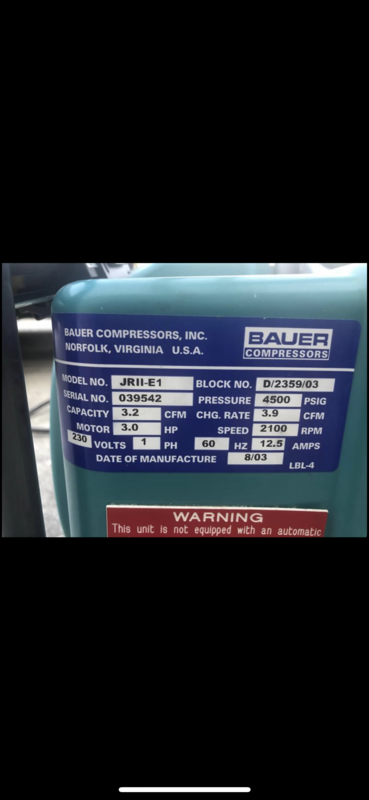

There's a guy selling this Bauer Junior 2 compressor manufactured in 08/03 this compressor is old and already past the 15 year life on the filter tower. The seller wants $600 for it. Is this a good price? And do i really need to buy a new filter tower or can i use the current one?

- The AGN App is ready! Search "Airgun Nation" in your App store. To compliment this new tech we've assigned the "Threads" Feed & "Dark" Mode. To revert back click HERE.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bauer Junior 2 help

- Thread starter miamiguy2017

- Start date

It looks very new in the photos 600$ or it is a scam or a great opportunity Bauer is the best in compressors

Upvote 0

I would buy it so fast your head would spin. I purchased a Bauer Utilus six years ago that was manufactured in 1991. I sold it to a paintball field that runs it every day and it has been flawless for them with heavy usage. I wouldn't be concerned in the least bit about the filter tower. It is built like a tank and that unit looks like it saw very light usage. Go for it but just verify that it's for real and not a scam. Finally, a Bauer built in 2003 is practically new. There are Bauers in service that were built 50 years ago. There is a reason fire departments, the military, and merchant ships all rely on Bauer compressors. They are the most well designed, long lasting, and best built compressor in the world. $600 is a STEAL. I hope you can buy it face to face to verify it's authenticity. It would be a buy at 4 times his asking price.

Upvote 0

I would buy it so fast your head would spin. I purchased a Bauer Utilus six years ago that was manufactured in 1991. I sold it to a paintball field that runs it every day and it has been flawless for them with heavy usage. I wouldn't be concerned in the least bit about the filter tower. It is built like a tank and that unit looks like it saw very light usage. Go for it but just verify that it's for real and not a scam. Finally, a Bauer built in 2003 is practically new. There are Bauers in service that were built 50 years ago. There is a reason fire departments, the military, and merchant ships all rely on Bauer compressors. They are the most well designed, long lasting, and best built compressor in the world. $600 is a STEAL. I hope you can buy it face to face to verify it's authenticity. It would be a buy at 4 times his asking price.

The guy selling it works with military contractors this was built for them but it never got sold and its been sitting unused since 2013, im worried that it sitting for so long has caused damage to the internals. This also comes with a bigger secondary filter tower auto condensate drain and a 60 minute carbon fiber tank.

Upvote 0

If that guy is around Miami and his name is Karlos Kuster, he is good. For that price, I'd take a chance, IF not a scam (do your homework). You can get all the parts you may need where I got my Bauer Jr II, August Industries in TX, who I can highly recommend, especially if you talk to Mr. Porter Stiles.

Upvote 0

I would buy it so fast your head would spin. I purchased a Bauer Utilus six years ago that was manufactured in 1991. I sold it to a paintball field that runs it every day and it has been flawless for them with heavy usage. I wouldn't be concerned in the least bit about the filter tower. It is built like a tank and that unit looks like it saw very light usage. Go for it but just verify that it's for real and not a scam. Finally, a Bauer built in 2003 is practically new. There are Bauers in service that were built 50 years ago. There is a reason fire departments, the military, and merchant ships all rely on Bauer compressors. They are the most well designed, long lasting, and best built compressor in the world. $600 is a STEAL. I hope you can buy it face to face to verify it's authenticity. It would be a buy at 4 times his asking price.

Can you take a look at the pictures below and tell me if this is some type of auto drain system and control panel? It has a filter system attached to it.

Upvote 0

I would buy it so fast your head would spin. I purchased a Bauer Utilus six years ago that was manufactured in 1991. I sold it to a paintball field that runs it every day and it has been flawless for them with heavy usage. I wouldn't be concerned in the least bit about the filter tower. It is built like a tank and that unit looks like it saw very light usage. Go for it but just verify that it's for real and not a scam. Finally, a Bauer built in 2003 is practically new. There are Bauers in service that were built 50 years ago. There is a reason fire departments, the military, and merchant ships all rely on Bauer compressors. They are the most well designed, long lasting, and best built compressor in the world. $600 is a STEAL. I hope you can buy it face to face to verify it's authenticity. It would be a buy at 4 times his asking price.

It looks very new in the photos 600$ or it is a scam or a great opportunity Bauer is the best in compressors

Can you take a look at the pictures below and tell me if this is some type of auto drain system and control panel? It has a filter system attached to it.

Upvote 0

Carlos Kuster couldn't be the seller of this Jr II. He wasn't born yesterday and would never sell one that cheap. I bought my Bauer from him years ago and he sells them at fair prices and goes through them before selling them but they are sold at competitive prices. This is a giveaway priced compressor.

Miamiguy2017, FYI just the black tower alone is a $600 plus item from Bauer. There is lots of extra plumbing and accessories attached to that unit that are "upgrades" but actually aren't necessary for an airgunner to have on his compressor. A lot of the extra plumbing creates the potential for leaks. You don't need the black filter tower in addition to the filtration in the gold tower on the Jr. II. The regulator box with the two gauges just prior to the DIN300 connector to a tank is also a $600 item. That is the most complicated setup for a Jr. II I've ever seen. It's incredibly underpriced unless its broken or stolen or a scam. If you can buy it locally and have it demonstrated, you should be buying it ASAP.

Miamiguy2017, FYI just the black tower alone is a $600 plus item from Bauer. There is lots of extra plumbing and accessories attached to that unit that are "upgrades" but actually aren't necessary for an airgunner to have on his compressor. A lot of the extra plumbing creates the potential for leaks. You don't need the black filter tower in addition to the filtration in the gold tower on the Jr. II. The regulator box with the two gauges just prior to the DIN300 connector to a tank is also a $600 item. That is the most complicated setup for a Jr. II I've ever seen. It's incredibly underpriced unless its broken or stolen or a scam. If you can buy it locally and have it demonstrated, you should be buying it ASAP.

Upvote 0

Carlos Kuster couldn't be the seller of this Jr II. He wasn't born yesterday and would never sell one that cheap. I bought my Bauer from him years ago and he sells them at fair prices and goes through them before selling them but they are sold at competitive prices. This is a giveaway priced compressor.

Miamiguy2017, FYI just the black tower alone is a $600 plus item from Bauer. There is lots of extra plumbing and accessories attached to that unit that are "upgrades" but actually aren't necessary for an airgunner to have on his compressor. A lot of the extra plumbing creates the potential for leaks. You don't need the black filter tower in addition to the filtration in the gold tower on the Jr. II. The regulator box with the two gauges just prior to the DIN300 connector to a tank is also a $600 item. That is the most complicated setup for a Jr. II I've ever seen. It's incredibly underpriced unless its broken or stolen or a scam. If you can buy it locally and have it demonstrated, you should be buying it ASAP.

Thanks for that info. What can you tell me about the other pictures with what looks to be an auto condensate drain with some type of moisture filter that looks like the ones used on paint spray guns.

Upvote 0

I've never seen a Bauer with that many extra attachments. Most of them aren't necessary for your purposes. Yes that does look like an auto condensate drain. Yes that looks like an intake moisture filter. All of them are unnecessary for your purposes. Unless you're filling a new tank for the first and only time, the fill time to top off the largest carbon fiber tank from 3k to 4.5K is shorter than the time necessary to manually drain the condensate collected by a Bauer. The large extra filter tower is also unnecessary because the filter in the gold tower is more than adequate to catch any residual moisture that the water separator stage misses. I would buy that compressor and just remove all the extras. At $600 you could sell the tower, that regulator, and practically net the compressor for free. The compressor alone is worth over $2,000, assuming it's working properly. As I said previously, a 2003 Bauer Jr ii is practically new.

Upvote 0

I've never seen a Bauer with that many extra attachments. Most of them aren't necessary for your purposes. Yes that does look like an auto condensate drain. Yes that looks like an intake moisture filter. All of them are unnecessary for your purposes. Unless you're filling a new tank for the first and only time, the fill time to top off the largest carbon fiber tank from 3k to 4.5K is shorter than the time necessary to manually drain the condensate collected by a Bauer. The large extra filter tower is also unnecessary because the filter in the gold tower is more than adequate to catch any residual moisture that the water separator stage misses. I would buy that compressor and just remove all the extras. At $600 you could sell the tower, that regulator, and practically net the compressor for free. The compressor alone is worth over $2,000, assuming it's working properly. As I said previously, a 2003 Bauer Jr ii is practically new.

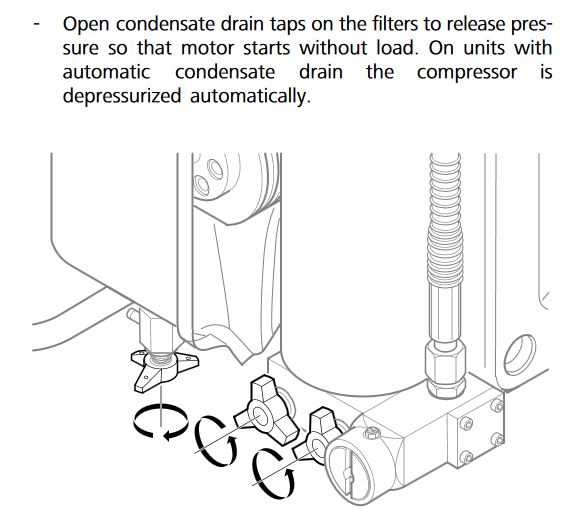

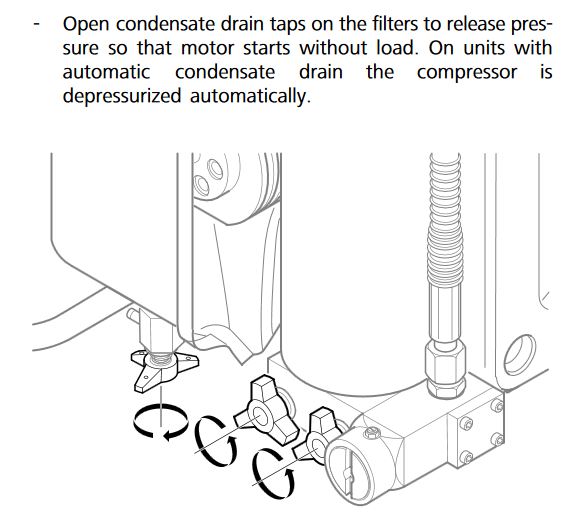

If you look at the picture below theres 3 drain plugs circled in red on this compressor that you can open and close by hand, even though it has auto drain, do u know in what order i should open and close these drains like before i start the compressor and after i shut it off? Or do i only need to mess with the one on the right with the black thumbscrew at the base of the filter tower that is not connected to the auto drain system?

Upvote 0

Hi MiamiGuy2017,

A little google action and you can get the operators manual for the Bauer Jr. 2. At $600, buy it now. Bring a tank and run it up to 200 bar. That will tell you if the compressor is ok. If it can't make 200 bar there are problems. Read the manual before you go. Bauer even has videos on how to start, stop, and maintain their compressors. This late of a unit will run on synthetic oil (0024) rather than the mineral oils. If you don't get a log book with the unit, I'd check the oil level and run it enough to get it warm and do an oil change. Also verify that it has an intake air filter. Just the little paper filter under the grey cover. You don't want to run w/o one.

Also verify the regulated pressure from the filter tower (gold thing with knob on top). There should be a tag on it that indicates what relief pressure is set. It could be 3200psi. Keep that in mind when you fill a tank. The relief valve can be adjusted to a higher pressure on a unit this late.

I picked up a nice Jr. from 2014 from Indiantown a few months back. It looked new and is only 6 years old. The one you are looking at could be a better deal. (Even if you want to change the filter tower for a new Bauer unit, the part is $1400.) Most folks don't seem to worry about the life recommendations for pressure vessels on the Bauer compressors. For myself, I promised a few folks dear to me that I wouldn't cut corners with HPA.

Best to spend some time with the operators manual. These are not hard to run but you want to look like you know the unit when you test it.

Good luck,

Nugria

ps. Your question answered via the manual. Left "tap" is on the inlet side of the tower, Right "tap" is on the outlet side of the tower. I start with the left most in your photo. This is the intermediate seperator:

INTERMEDIATE SEPARATOR MAINTENANCE Proper operation will rely on the intermediate separator being properly serviced.Open drain tap (1, Fig. 31) and drain off condensate every 15to 30 minutes during operation.

Drain condensate from separator and cartridge chamberregularly by slowly opening drain taps (2 and 3, Fig. 31)-before changing cartridge-before each filling procedure-during filling procedure every 15 minutes.Slowly open left tap first, then right tap approx. 1/3 turn tothe left, until condensate is completely drained. The tapsclose by spring pressure, if necessary tighten by hand tomake sure they are completely air-tight

A little google action and you can get the operators manual for the Bauer Jr. 2. At $600, buy it now. Bring a tank and run it up to 200 bar. That will tell you if the compressor is ok. If it can't make 200 bar there are problems. Read the manual before you go. Bauer even has videos on how to start, stop, and maintain their compressors. This late of a unit will run on synthetic oil (0024) rather than the mineral oils. If you don't get a log book with the unit, I'd check the oil level and run it enough to get it warm and do an oil change. Also verify that it has an intake air filter. Just the little paper filter under the grey cover. You don't want to run w/o one.

Also verify the regulated pressure from the filter tower (gold thing with knob on top). There should be a tag on it that indicates what relief pressure is set. It could be 3200psi. Keep that in mind when you fill a tank. The relief valve can be adjusted to a higher pressure on a unit this late.

I picked up a nice Jr. from 2014 from Indiantown a few months back. It looked new and is only 6 years old. The one you are looking at could be a better deal. (Even if you want to change the filter tower for a new Bauer unit, the part is $1400.) Most folks don't seem to worry about the life recommendations for pressure vessels on the Bauer compressors. For myself, I promised a few folks dear to me that I wouldn't cut corners with HPA.

Best to spend some time with the operators manual. These are not hard to run but you want to look like you know the unit when you test it.

Good luck,

Nugria

ps. Your question answered via the manual. Left "tap" is on the inlet side of the tower, Right "tap" is on the outlet side of the tower. I start with the left most in your photo. This is the intermediate seperator:

INTERMEDIATE SEPARATOR MAINTENANCE Proper operation will rely on the intermediate separator being properly serviced.Open drain tap (1, Fig. 31) and drain off condensate every 15to 30 minutes during operation.

Drain condensate from separator and cartridge chamberregularly by slowly opening drain taps (2 and 3, Fig. 31)-before changing cartridge-before each filling procedure-during filling procedure every 15 minutes.Slowly open left tap first, then right tap approx. 1/3 turn tothe left, until condensate is completely drained. The tapsclose by spring pressure, if necessary tighten by hand tomake sure they are completely air-tight

Upvote 0

Hi MiamiGuy2017,

A little google action and you can get the operators manual for the Bauer Jr. 2. At $600, buy it now. Bring a tank and run it up to 200 bar. That will tell you if the compressor is ok. If it can't make 200 bar there are problems. Read the manual before you go. Bauer even has videos on how to start, stop, and maintain their compressors. This late of a unit will run on synthetic oil (0024) rather than the mineral oils. If you don't get a log book with the unit, I'd check the oil level and run it enough to get it warm and do an oil change. Also verify that it has an intake air filter. Just the little paper filter under the grey cover. You don't want to run w/o one.

Also verify the regulated pressure from the filter tower (gold thing with knob on top). There should be a tag on it that indicates what relief pressure is set. It could be 3200psi. Keep that in mind when you fill a tank. The relief valve can be adjusted to a higher pressure on a unit this late.

I picked up a nice Jr. from 2014 from Indiantown a few months back. It looked new and is only 6 years old. The one you are looking at could be a better deal. (Even if you want to change the filter tower for a new Bauer unit, the part is $1400.) Most folks don't seem to worry about the life recommendations for pressure vessels on the Bauer compressors. For myself, I promised a few folks dear to me that I wouldn't cut corners with HPA.

Best to spend some time with the operators manual. These are not hard to run but you want to look like you know the unit when you test it.

Good luck,

Nugria

ps. Your question answered via the manual. Left "tap" is on the inlet side of the tower, Right "tap" is on the outlet side of the tower. I start with the left most in your photo. This is the intermediate seperator:

INTERMEDIATE SEPARATOR MAINTENANCE Proper operation will rely on the intermediate separator being properly serviced.Open drain tap (1, Fig. 31) and drain off condensate every 15to 30 minutes during operation.

Drain condensate from separator and cartridge chamberregularly by slowly opening drain taps (2 and 3, Fig. 31)-before changing cartridge-before each filling procedure-during filling procedure every 15 minutes.Slowly open left tap first, then right tap approx. 1/3 turn tothe left, until condensate is completely drained. The tapsclose by spring pressure, if necessary tighten by hand tomake sure they are completely air-tight

Hey man the manual doesnt mention the third leftmost tap, only the 2 by the base of the filter tower.

Upvote 0

Hi MiamiGuy2017,

A little google action and you can get the operators manual for the Bauer Jr. 2. At $600, buy it now. Bring a tank and run it up to 200 bar. That will tell you if the compressor is ok. If it can't make 200 bar there are problems. Read the manual before you go. Bauer even has videos on how to start, stop, and maintain their compressors. This late of a unit will run on synthetic oil (0024) rather than the mineral oils. If you don't get a log book with the unit, I'd check the oil level and run it enough to get it warm and do an oil change. Also verify that it has an intake air filter. Just the little paper filter under the grey cover. You don't want to run w/o one.

Also verify the regulated pressure from the filter tower (gold thing with knob on top). There should be a tag on it that indicates what relief pressure is set. It could be 3200psi. Keep that in mind when you fill a tank. The relief valve can be adjusted to a higher pressure on a unit this late.

I picked up a nice Jr. from 2014 from Indiantown a few months back. It looked new and is only 6 years old. The one you are looking at could be a better deal. (Even if you want to change the filter tower for a new Bauer unit, the part is $1400.) Most folks don't seem to worry about the life recommendations for pressure vessels on the Bauer compressors. For myself, I promised a few folks dear to me that I wouldn't cut corners with HPA.

Best to spend some time with the operators manual. These are not hard to run but you want to look like you know the unit when you test it.

Good luck,

Nugria

ps. Your question answered via the manual. Left "tap" is on the inlet side of the tower, Right "tap" is on the outlet side of the tower. I start with the left most in your photo. This is the intermediate seperator:

INTERMEDIATE SEPARATOR MAINTENANCE Proper operation will rely on the intermediate separator being properly serviced.Open drain tap (1, Fig. 31) and drain off condensate every 15to 30 minutes during operation.

Drain condensate from separator and cartridge chamberregularly by slowly opening drain taps (2 and 3, Fig. 31)-before changing cartridge-before each filling procedure-during filling procedure every 15 minutes.Slowly open left tap first, then right tap approx. 1/3 turn tothe left, until condensate is completely drained. The tapsclose by spring pressure, if necessary tighten by hand tomake sure they are completely air-tight

This third rear facing tap in the picture below is not mentioned in the manual at all so i have no clue what to do with it.

Upvote 0

Why don't you just ask the guy that you bought it off? You mentioned that he was modifying these for military use. The extra plumbing appears to be linked to an auto purge set up with a trap to filter the wasted air. It's probably a Navy specification. In the short term, you shouldn't need to play with that part. Just fill your bottle and purge as of the instructions. If it worries you, just remove it, it isn't necessary for civil use but it shouldn't cause you any problems.

Upvote 0

Hi Miami Guy,

Read back (toward the beginning) of the manual. The tap on the left is for the intermediate separator. Yours has some extra plumbing but the left most tap should be at the bottom of a pointed, tubular part (silver) with the point at the bottom. It separates oil/water between the second and third stage IIRC. Did you bring it home? !!!!

!!!!

Read back (toward the beginning) of the manual. The tap on the left is for the intermediate separator. Yours has some extra plumbing but the left most tap should be at the bottom of a pointed, tubular part (silver) with the point at the bottom. It separates oil/water between the second and third stage IIRC. Did you bring it home?

Upvote 0

Hi Miami Guy,

Read back (toward the beginning) of the manual. The tap on the left is for the intermediate separator. Yours has some extra plumbing but the left most tap should be at the bottom of a pointed, tubular part (silver) with the point at the bottom. It separates oil/water between the second and third stage IIRC. Did you bring it home?!!!!

Yes i brought it home and tested it seems to work fine.With the auto drain it seems that i dont have to bleed it manually at all, after the auto drain goes off automatically, i manually open all the bleeder thumbscrews and no air comes out. Can you take a look at the pictures of the control panel below, the black hose circled in red with 3 wires coming out of it is the auto drain wiring. The black round wheel circled in red on the left has the word A maybe that means amps and the numbers 18 through 30. The smaller light blue wheel circled in red on the right has the words M res and A i have no clue what those mean but right now its set to M. Do you know if these settings circled in red are for the auto drain system or is it for the compressor to shut off at a certain amp value?

Upvote 0