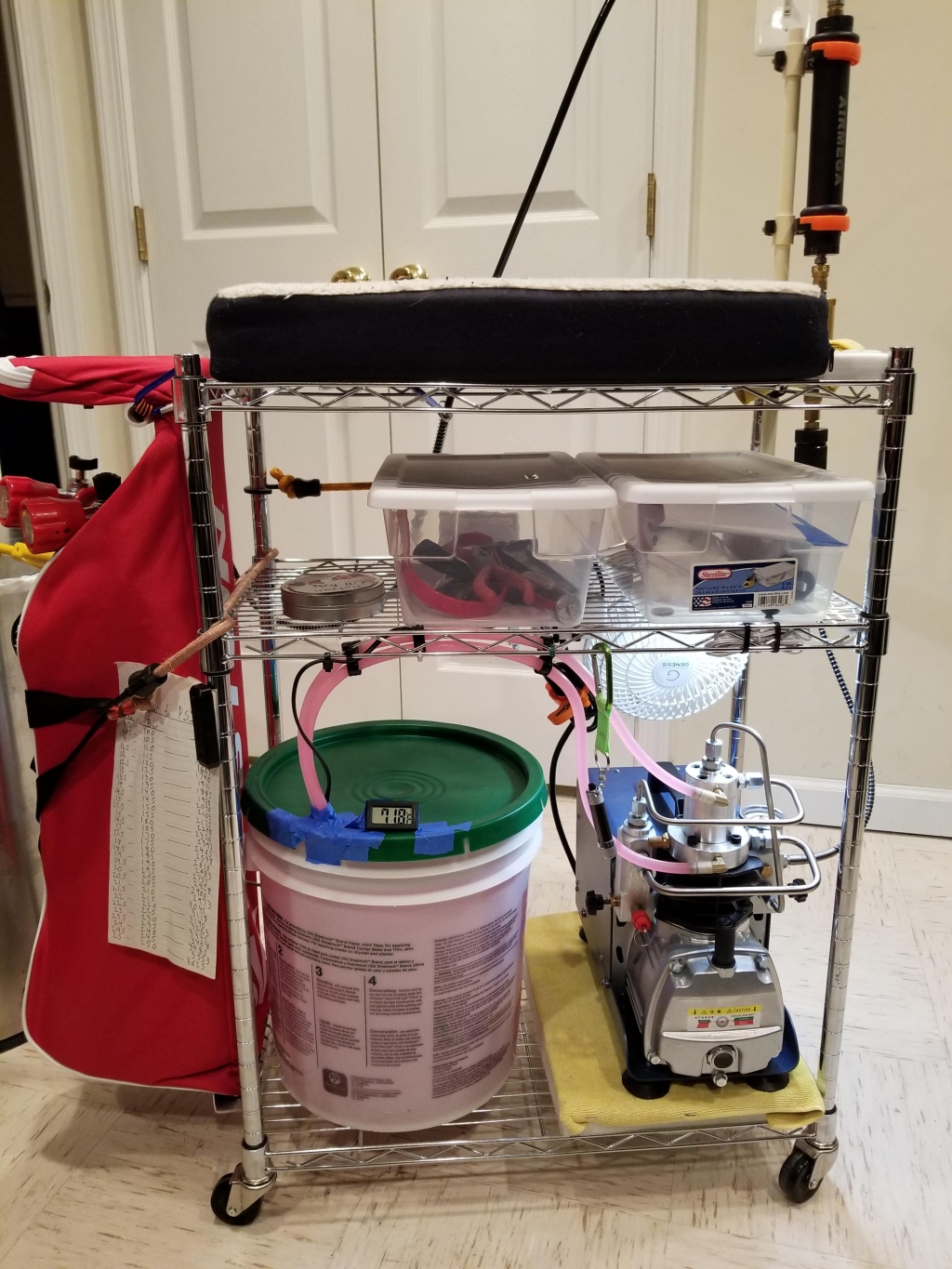

Not long after getting my Yong Heng I found posts from people who used radiators and computer fans to help cool their compressors. Neat idea but seems to me to be quite a bit of $$ to put together. I like to tinker (on the cheap) so I thought I'd try a poor man's version. The "before" set up:

The YH works perfectly well for SHORT run times with just water in the bucket. With ice in the bucket I can extend the run time. I worried about water left in the bucket getting "funky" and forming mineral deposits. I filled the bucket each time which was a bit of a pain but sure beats hand pumping. I thought about adding Water Wetter (which I did do later) to stop the "funk". That would then limit me to short fill times - can't add ice - or I would have to use frozen water bottles - I did not want to clean them afterwards. I wanted to be able to have my Yong Heng set up and ready to go for short fills of guns or topping off my 90 cuin bottle but also be able to fill my 6.8L tank with longer run times (additional cooling needed).

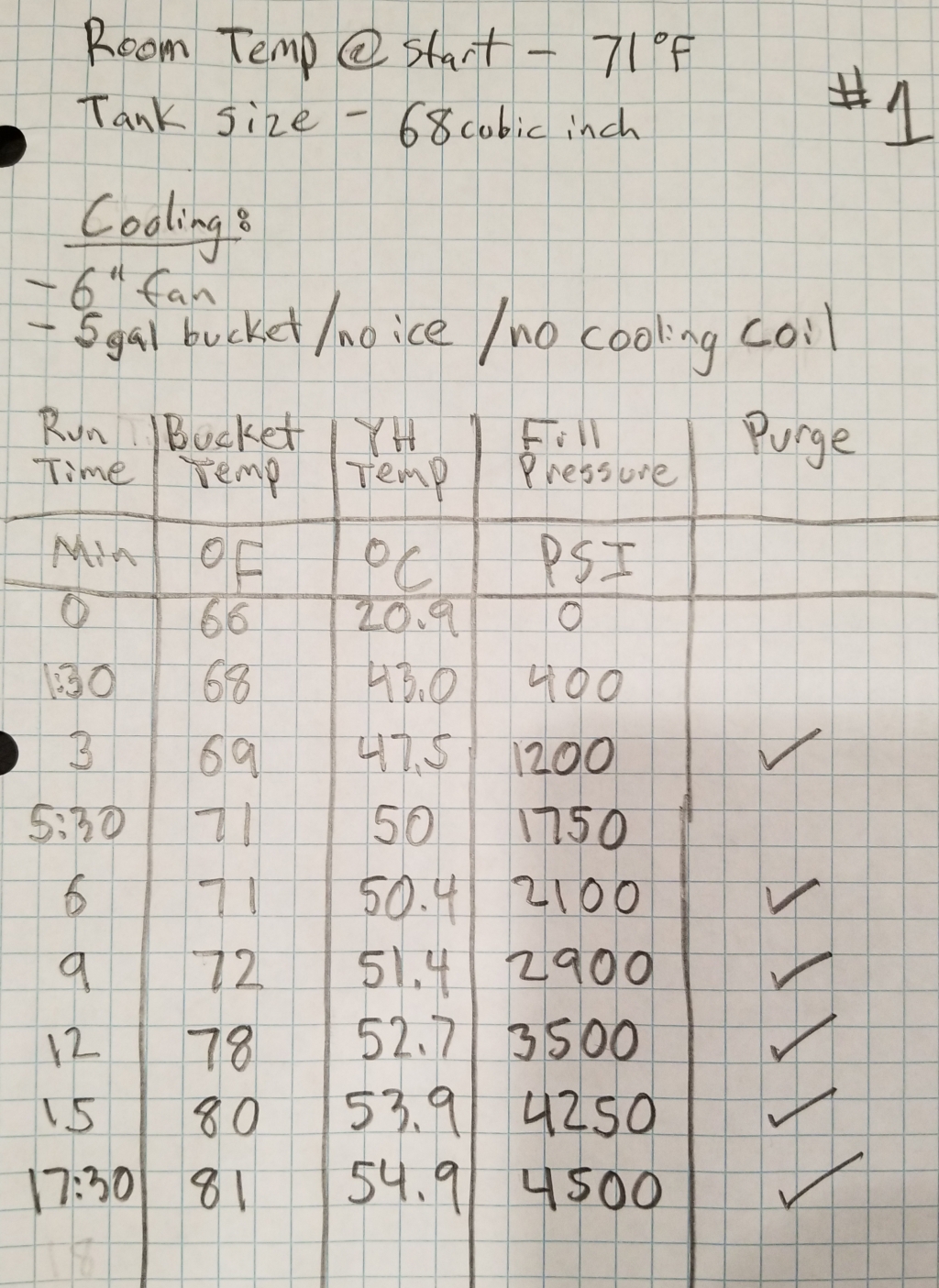

Enough marinating, here's the meat. Lol. I used a 20' length of 3/8 copper tubing, a wet saw pump, and some vinyl tubing and started experimenting. First a baseline test. Just a 6" fan blowing on the compressor head (this was used in each test) and a bucket of water- no ice:

I do have Water Wetter added. These tests were done over a 6 month period and not in the order that I'm presenting them. I mention this because I bought a 3 pack of gauges for the YH that read in °F instead of °C part way thru this process. I started with a metal probe style thermometer for the bucket temp then switched to the more accurate °F unit. Yes, I know that I should have used the same testing set up for consistancy. When I started this project it was for my own curiosity. I did not have posting the results in mind.

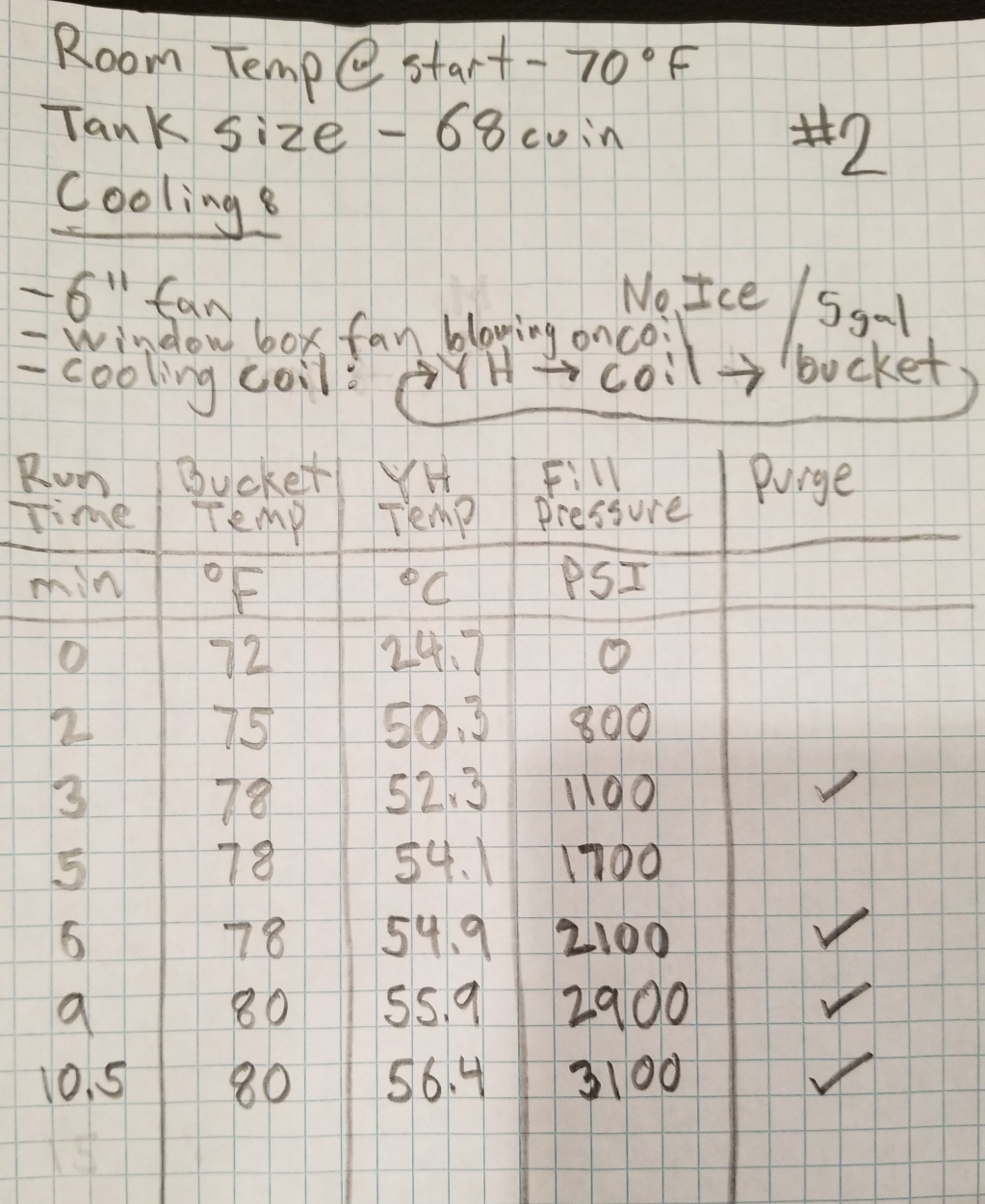

Next test. Plumb the copper coil in line to receive the heated water from the YH then into the bucket to be recirculated. Additional window box fan blowing on the coil.

This had just the opposite effect that I thought would happen. Temp went up more rapidly. I think that the coil restricted the water flow too much.

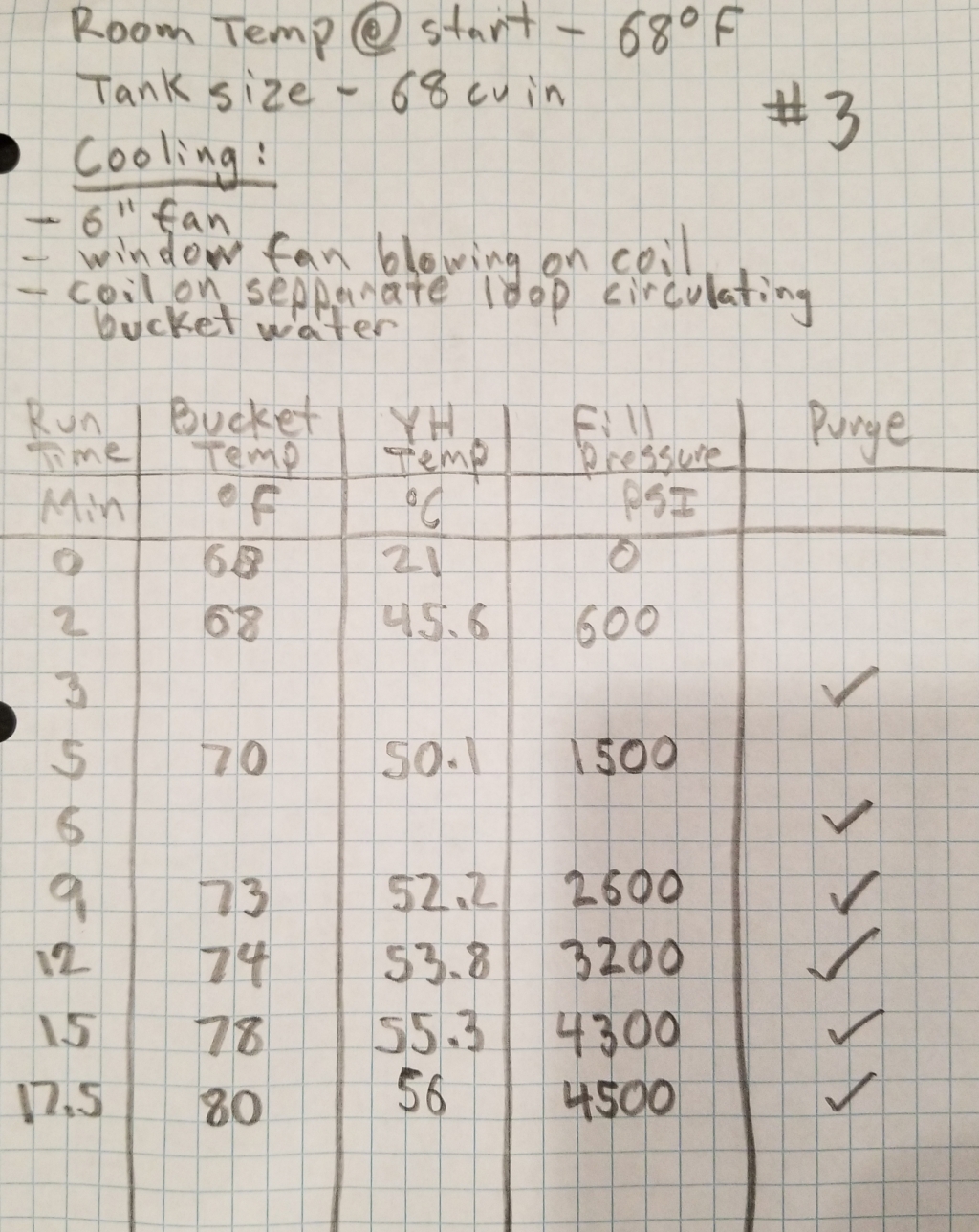

Next test. Use a second water pump to circulate water from the bucket thru the coil and back to the bucket. Use the box fan to cool the coil. Original YH pump circulates bucket water thru compressor.

No improvement over baseline test.

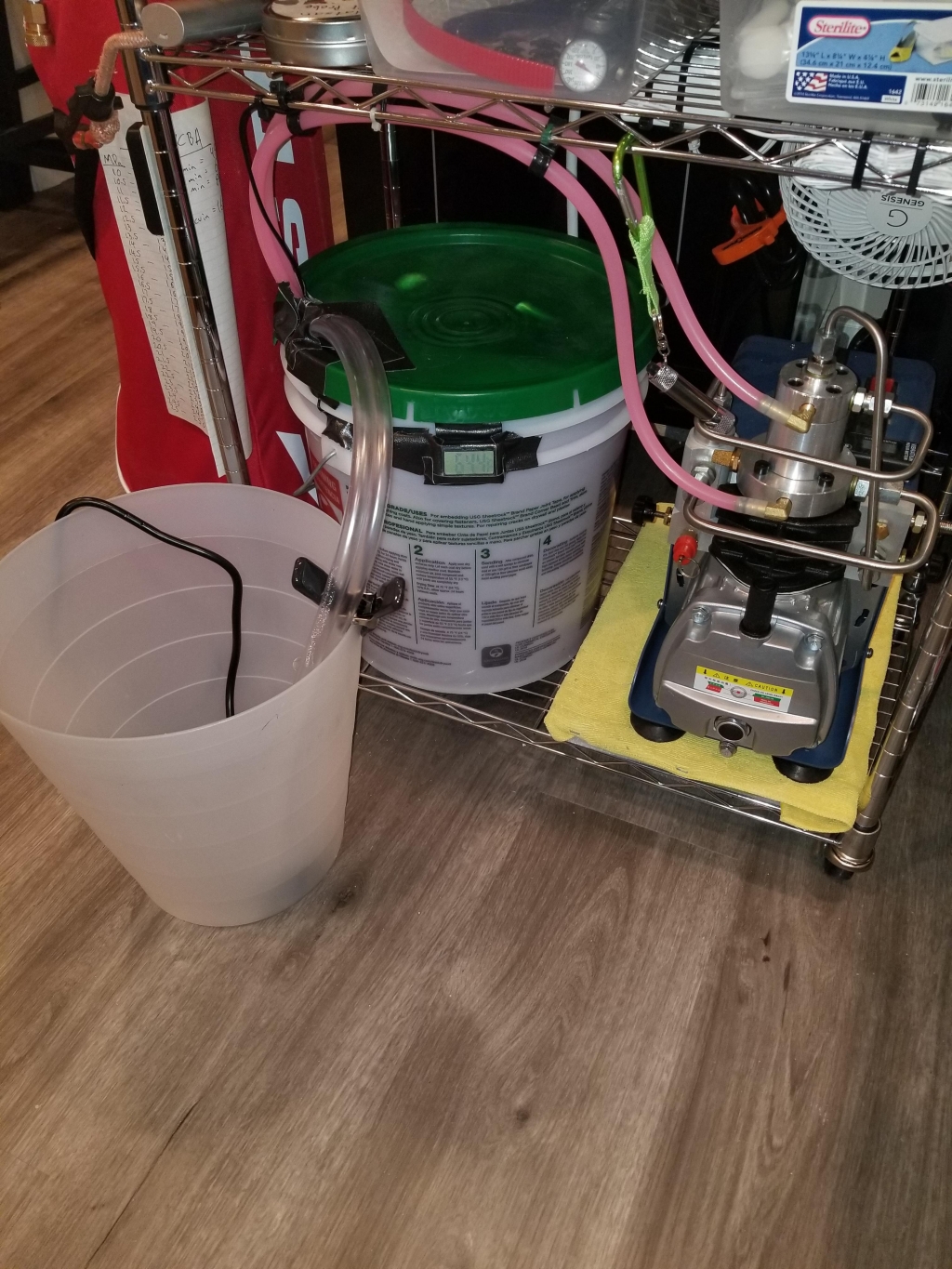

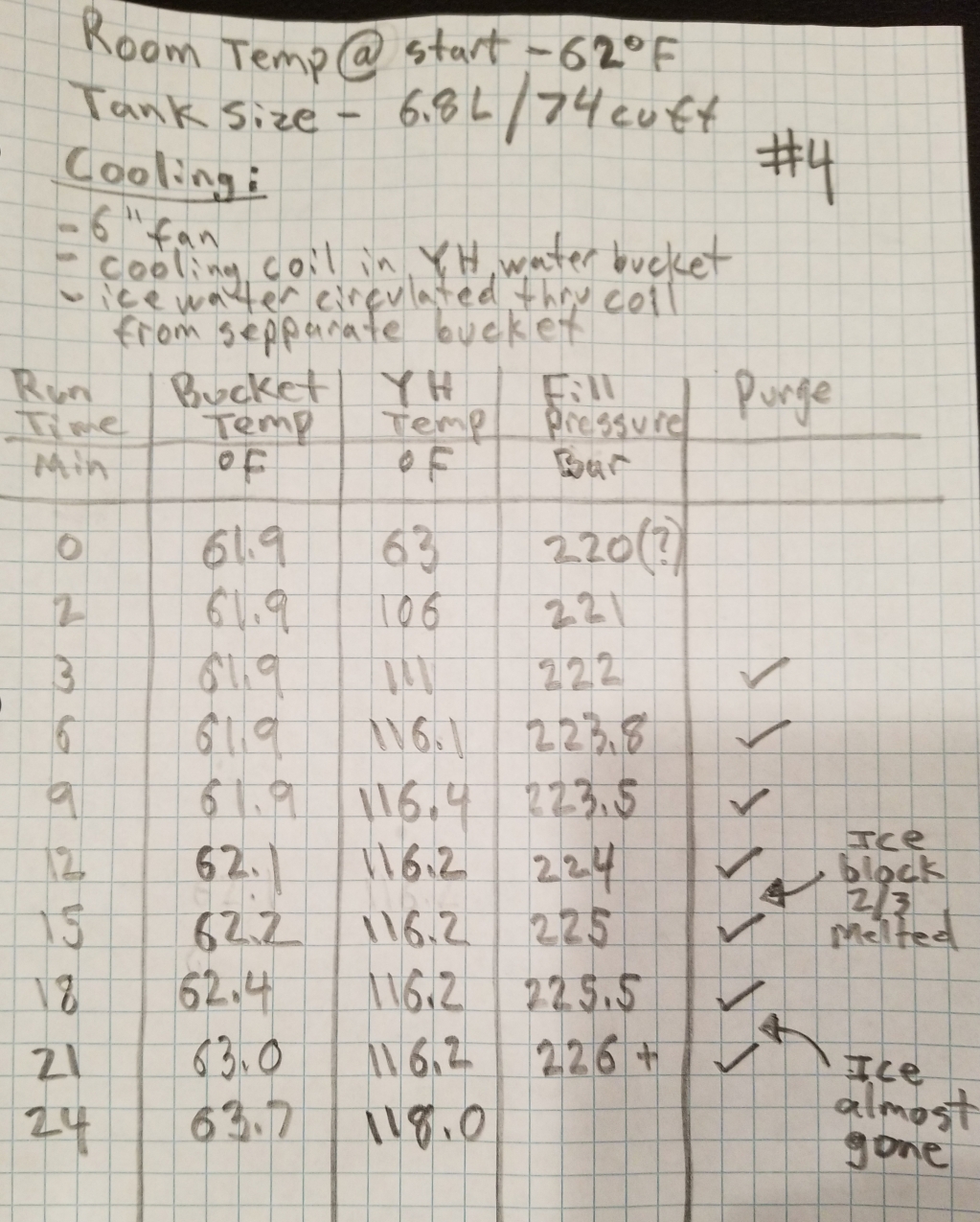

Next test. This time I put the coil in the bucket and circulated ice water thru the coil from a second pail. YH water pump circulates bucket water thru compressor. Second pump/pail (ice water) chills water in bucket.

Again, the idea being to have a "ready-to-go" no hassel set up for short run time fills with the ability to use additional cooling for filling large tanks.

I was kind of surprised at how well it actually worked. Surprised enough that I ran this test a second time to confirm the results. From the 6th minute to the 21st minute the temp held at a consistent 116 °F. Only after the ice was depleted did the temp start to rise. Seems like more ice would make for an even longer run time. When done the second pump and tubing coil up and store on top of the main bucket.

The YH works perfectly well for SHORT run times with just water in the bucket. With ice in the bucket I can extend the run time. I worried about water left in the bucket getting "funky" and forming mineral deposits. I filled the bucket each time which was a bit of a pain but sure beats hand pumping. I thought about adding Water Wetter (which I did do later) to stop the "funk". That would then limit me to short fill times - can't add ice - or I would have to use frozen water bottles - I did not want to clean them afterwards. I wanted to be able to have my Yong Heng set up and ready to go for short fills of guns or topping off my 90 cuin bottle but also be able to fill my 6.8L tank with longer run times (additional cooling needed).

Enough marinating, here's the meat. Lol. I used a 20' length of 3/8 copper tubing, a wet saw pump, and some vinyl tubing and started experimenting. First a baseline test. Just a 6" fan blowing on the compressor head (this was used in each test) and a bucket of water- no ice:

I do have Water Wetter added. These tests were done over a 6 month period and not in the order that I'm presenting them. I mention this because I bought a 3 pack of gauges for the YH that read in °F instead of °C part way thru this process. I started with a metal probe style thermometer for the bucket temp then switched to the more accurate °F unit. Yes, I know that I should have used the same testing set up for consistancy. When I started this project it was for my own curiosity. I did not have posting the results in mind.

Next test. Plumb the copper coil in line to receive the heated water from the YH then into the bucket to be recirculated. Additional window box fan blowing on the coil.

This had just the opposite effect that I thought would happen. Temp went up more rapidly. I think that the coil restricted the water flow too much.

Next test. Use a second water pump to circulate water from the bucket thru the coil and back to the bucket. Use the box fan to cool the coil. Original YH pump circulates bucket water thru compressor.

No improvement over baseline test.

Next test. This time I put the coil in the bucket and circulated ice water thru the coil from a second pail. YH water pump circulates bucket water thru compressor. Second pump/pail (ice water) chills water in bucket.

Again, the idea being to have a "ready-to-go" no hassel set up for short run time fills with the ability to use additional cooling for filling large tanks.

I was kind of surprised at how well it actually worked. Surprised enough that I ran this test a second time to confirm the results. From the 6th minute to the 21st minute the temp held at a consistent 116 °F. Only after the ice was depleted did the temp start to rise. Seems like more ice would make for an even longer run time. When done the second pump and tubing coil up and store on top of the main bucket.