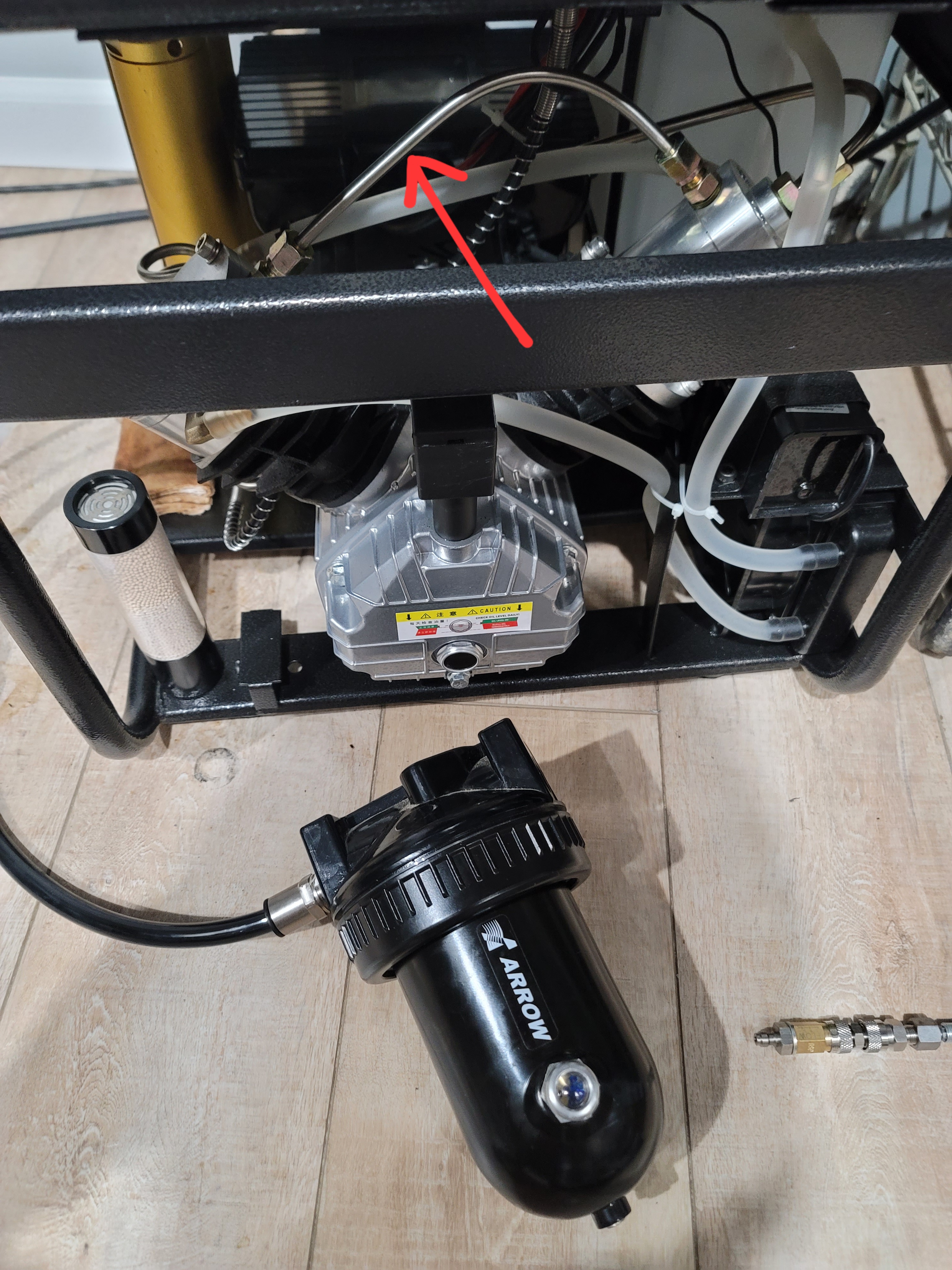

I've had an idea for a while to add a dessicant trap between stages on my tuxing compressor.

First I'm wondering if anyone has measured the pressure between these stages. The bowl I have is labeled up to 250psi. Figured I'd ask before I start disassembling those fittings as they seem to be stuck.

I've been using it as a prefilter for a while now. Definitely seems to reduce the moisture leaving the bleed screw, but I imagine it would be even better under pressure.

Side question: the air from this thing stinks like oil. Any budget methods to improve the air purity?

First I'm wondering if anyone has measured the pressure between these stages. The bowl I have is labeled up to 250psi. Figured I'd ask before I start disassembling those fittings as they seem to be stuck.

I've been using it as a prefilter for a while now. Definitely seems to reduce the moisture leaving the bleed screw, but I imagine it would be even better under pressure.

Side question: the air from this thing stinks like oil. Any budget methods to improve the air purity?